TE Connectivity

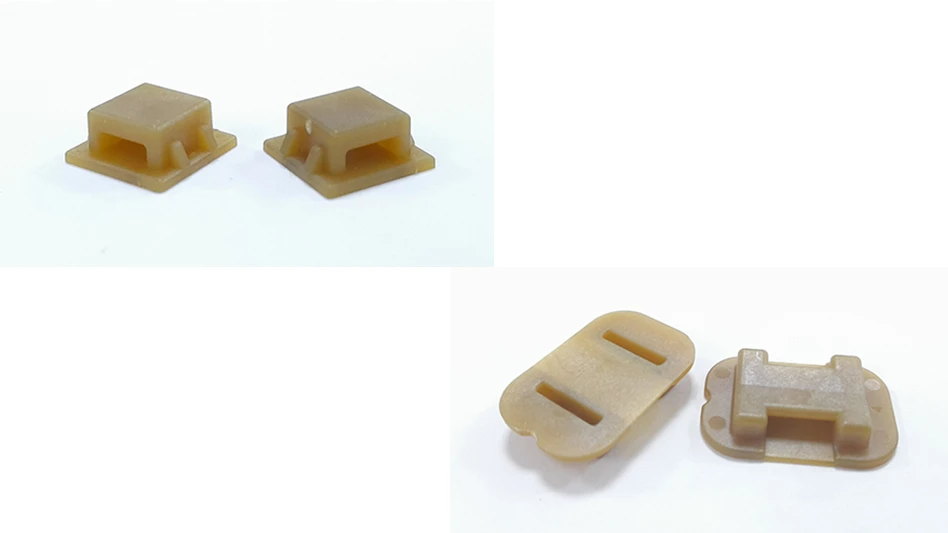

TE Connectivity (TE), a world leader in connectivity and sensors, has expanded its portfolio of cable management solutions with the launch of its latest standard and miniature cable tie adhesive mount brackets. Designed to support equipment in pressurized and unpressurized areas of an aircraft, these lightweight brackets support quick installation with recommended adhesives while maintaining structural integrity.

These latest adhesive mount brackets significantly reduce the need for drilled holes and structural modifications, preventing potential issues such as fatigue cracks on metal surfaces due to incorrect drilling. The brackets' enhanced strength-to-weight ratio and compact footprint help save both weight and space while maintaining performance. Each bracket accommodates a range of industry-standard cable tie sizes, reducing the need for multiple hardware components and part numbers.

"TE's latest adhesive mount brackets provide a versatile, standardized solution for efficient cable management in aerospace applications," says Stephen Rosenbauer, Product Manager at TE Connectivity. "The brackets' lightweight, space-saving design and quick installation process make them a highly reliable choice for customers seeking to fine tune cable routing while maintaining high levels of performance and reliability."

Key features and benefits:

- Space efficiency: Both brackets are engineered to occupy minimal space, allowing for enhanced utilization of functional requirements.

- Ease of assembly: The brackets support a range of industry-standard cable tie sizes, providing for a smooth installation process.

- Industry approved: The brackets conform to several industry standards including RTCA-DO-160, EN2591 and EN3909.

- Weight savings: The standard bracket’s bonding surface pocket weighs less than other in-market products when considered with the same raw material, which helps to optimize strength while providing a weight savings of approximately 16% per product.

- Structural integrity: The adhesive design of the brackets significantly reduces the need for drilled holes and structural modifications, preventing fatigue cracks and corrosion on metal surfaces.

TE's adhesive mount brackets are well-suited for various aerospace applications such as attaching wiring, cables, conduits, sensors, lighting and acoustic panels in both eVTOL and commercial aircraft.