Sumitomo

Sumitomo has developed AC4125K to reduce machining costs by lowering overall tool usage and tool change frequency through stable and long tool life in cast iron applications. Many of these cast iron applications are featured in the automotive industry, among others. Gray cast iron is used for parts like engine blocks and brake discs where sliding is required, while ductile cast iron is used for parts such as differential cases and carrier cases where strength is required. Gray cast iron is an alloy primarily composed of carbon (C) and silicon (Si), with C content of 2.1% or more. Gray cast iron appears gray on the fracture surface because carbon is more present in the form of graphite than in the form of cementite. Ductile cast iron contains somewhat more carbon and silicon than gray iron, with the graphite becoming spherical due to the addition of magnesium and/or cerium.

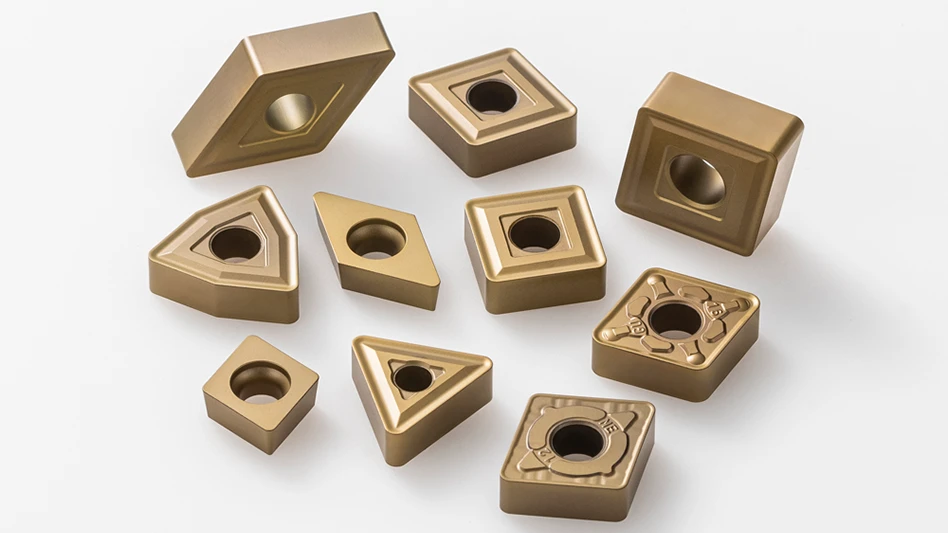

AC4125K is Sumitomo’s 1st recommended grade for interrupted machining of cast iron. Using Absotech Coating, the proprietary CVD coating technology, to provide excellent chipping resistance by maximizing compressive stress to achieve stable and longer tool life for roughing of components such as differential cases and carrier cases. Also, the gold color inserts make it easy to identify used corners, assisting in the improvement of tool management.

AC4125K is Sumitomo’s 1st recommended grade for interrupted machining of cast iron. Using Absotech Coating, the proprietary CVD coating technology, to provide excellent chipping resistance by maximizing compressive stress to achieve stable and longer tool life for roughing of components such as differential cases and carrier cases. Also, the gold color inserts make it easy to identify used corners, assisting in the improvement of tool management.