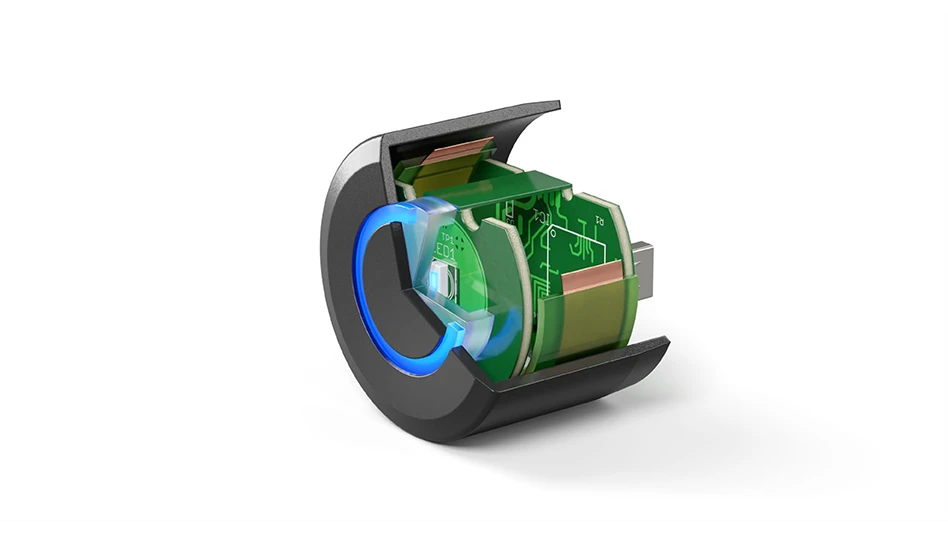

Based on the company’s capacitive capaTEC technology, EBE sensors + motion is developing a rotary encoder without any mechanical parts. The rotary encoder is set by a sliding movement of several fingers across a cylinder. The operator’s fingers serve as individual influencing factors that can be detected via capacitive measurement. Electrodes introduced from within are adjusted inside the rotary encoder via a carrier element. The housing wall remains completely closed and contains no mechanical or otherwise rotating components.

The advantages of such a rotary encoder are obvious. The concept is absolutely tight. As the bulge for the sensor rotary encoder is directly cast into the front panel of the end device, the surface remains completely closed. It can be ideally integrated into acrylic glass or plastic surfaces. Without any movable parts, wear by friction or contamination is excluded. Thus, the whole system is extremely resilient to ambient conditions and easy to install.

By means of its dynamic operating concept, the rotary encoder can be switched from a continuous control element to a step switch during operation. The resolution of the rotary encoder can also be flexibly adapted to additionally required manipulated variables. Not only the operation of the sensor rotary encoder can be adapted; the size and diameter of the encoder, the number of sensor surfaces, the resolution or the integration of haptic feedback can also be individually implemented according to the respective requirements of the application. Furthermore, it is possible to realize an additional button function and, alternatively, a display on the front side of the rotary encoder. With this novel solution it is possible to develop completely new operating surface designs.

The capacitive rotary encoder is particularly suitable in environments that need to be regularly cleaned or disinfected. The new technology also convinces in industrial environments and the outdoor area. Here, dust and humidity are often a challenge for conventional rotary encoders and switches. In contrast, the new sensor rotary encoder offers an attractive alternative.