Multiaxis machining can dramatically increase a shop’s competitiveness. Mastercam’s multiaxis machining offers a wide range of multiaxis machining strategies – both basic and advanced. With Mastercam, you have complete control over the three crucial elements of multiaxis machining – Cut Pattern, Tool Axis Control, and Collision Control. Mastercam X5 introduces a unified interface and a streamlined workflow for generating multiaxis toolpaths.

Cut Patterns

Cut Patterns guide the tool along specified paths. These patterns can be simple 2D and 3D wireframe, solid primitives (for example, box, cylinder, or sphere), or complex multisurface grids.

Mastercam’s Multiaxis machining has many toolpath types to govern the cut pattern including:

- Curve wireframe for trimming operations

- Swarf fanning and swarf machining over multisurface floors, plus rail swarf cutting for added control

- Multisurface 5-axis roughing and finishing, including depth cuts, plunge roughing, and flowline machining and drilling

- Stock recognition that trims toolpaths to eliminate air-cuts and drastically reduce cycle times

- Custom applications for machining cylinder heads and converting probe data to machinable geometry

- And Mastercam X5 introduces eight new triangular mesh multiaxis toolpaths that support surface, solid, and STL input

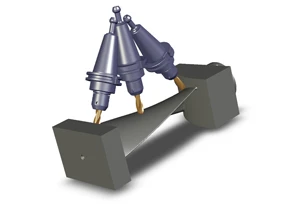

Tool Axis Control

Mastercam’s Tool Axis Control allows orientation of the tool’s center axis to be manipulated as it follows the cut pattern. You have complete and dynamic control over the tool axis, lead/lag, entry/exit, and tilt, which simplifies even the most difficult multiaxis jobs. Full entry and exit control lets you determine exactly where and how the cutter enters and leaves your part. An automatic point generator adds greater precision, as well as advanced gouge checking and a 5-axis safe zone around the part.

Powerful axis limits control tool motion between defined angles, ensuring that the tool tilt does not violate part or machine tool limits. You can easily refine control of your tool axis with a few simple pieces of CAD geometry. Shank containment simplifies cutting in confined areas.

Collision Control

When programming 5-axis parts, it is often necessary to come very close to the part or fixture with either the cutter, arbor, or the holder. Mastercam gives you “near miss tolerance” fields so you can specify how close you are willing to get with any part of the tool and how to avoid those situations.

Streamlined Multiaxis Interface

Mastercam X5 introduces a unified interface and a streamlined workflow for multiaxis toolpaths. The selection screen tree structure changes based on toolpath family and type selections. The tree is laid out in the logical order of setting your toolpath parameters. Simply advance along the tree structure, choosing your options and setting your parameters along the way, to create the desired multiaxis toolpath.

For more information on Mastercam’s Multiaxis machining, please visit http://www.mastercam.com/Products/Multiaxis/Default.aspx.

About Mastercam

Developed by CNC Software, Inc., Mastercam is Windows®-based CAD/CAM software for 2- through 5-axis routing, milling and turning, 2- and 4-axis wire EDM, 2D and 3D design, surface and solid modeling, and artistic relief cutting. CNC Software is a privately owned corporation founded in 1984. The U.S.-based company provides Mastercam CAD/CAM solutions to more than 150,000 installations in 75 countries in industries including mold-making, prototyping, automotive, medical, aerospace, and consumer products. Mastercam runs under Windows 7, Windows Vista®, and Windows XP, and is compatible with all other CAD/CAM systems. For more information about CNC Software, Inc. and its Mastercam family of products, contact CNC Software, Inc., M - F, 8 AM - 6 PM EST at (800) 228-2877 or (860) 875-5006,—671 Old Post Road, Tolland, CT 06084. Or visit www.mastercam.com.