MIDACO Corporation

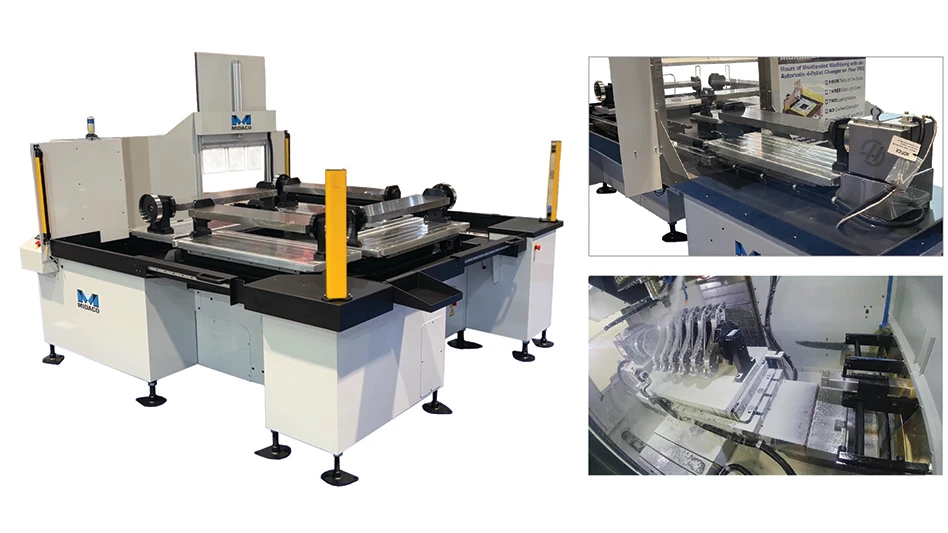

MIDACO Corporation, a leader in machining productivity solutions, launched its Automatic 4-Pallet Changer with Trunnion System for CNC machining, as seen at this past IMTS 2024. Designed for seamless integration with Vertical Machining Centers (VMCs), this system optimizes workflows by eliminating idle time, maximizing spindle utilization, and increasing flexibility for complex jobs.

High-volume, mixed-job efficiency with four-pallet shuttle

MIDACO’s four-pallet shuttle system is engineered for both high-volume production and low-volume, high-mix jobs, enabling continuous operation without interruption. Operators can stage multiple ops of a production job or load a series of different parts on four pallets, which automatically shuttle into the machining area when the spindle completes a cycle. This setup enables operators to load and unload parts on one pallet while machining continues on another, reducing idle time and exponentially increasing productivity.

Built for robust, flexible capacity

MIDACO’s 4-Pallet Changer features durable cast aluminum or cast-iron pallets, in XY sizes ranging from 28" x 15" (711mm x 381mm) to 50" x 24" (1270mm x 609mm). Each pallet is automatically transferred with +/- 0.0001” (0.0025mm) repeatability onto a cast-iron receiver mounted directly on the machine table that supports up to 500 lbs (226kg) for smaller models and up to 2,000 lbs (908kg) on larger models with weight evenly distributed. This system is powered by a servo drive and equipped with a rotary shuttle, automatic door, and CE light curtain for safety.

The shuttle system’s two loading stations allow clear access to all four pallets with no overhead obstruction, making it ideal for workflows requiring heavy part handling or crane loading.

Enhanced workholding flexibility with trunnion system for 4th-axis machining

For added versatility, MIDACO’s Automatic 4-Pallet Changer integrates a Trunnion System that enables 4th-axis operations on a 3-axis VMC. Equipped with four trunnions, the system uses a single 4th-Axis Rotary Indexer (not included) to power all trunnions, and eliminates any need for cable management, simplifying the process. This feature is ideal for shops handling parts with complex geometries, angled surfaces, or multi-sided components, making it possible to perform intricate work in a single setup. The included actuator assembly provides smooth, reliable trunnion movement and straightforward operation. The Trunnion System minimizes operator intervention, boosting throughput.

Efficient VMC integration and control

MIDACO’s 4-Pallet Changer is fully integrated with the VMC via M-codes, allowing operators to control the system directly from the VMC’s control panel. This ease of use reduces training time and enables faster production start-up, allowing operators to manage the pallet changer with confidence.

Powerful tool for modern machine shops

For machine shops looking to reduce idle time and handle more challenging jobs, MIDACO’s Automatic 4-Pallet Changer is the answer. With its durable build and advanced features, this system empowers any shop to maximize their CNC equipment’s potential by enabling uninterrupted machining, expand part-loading capacity, and integrate 4th-axis machining on their new or existing 3-axis equipment to stay competitive in an evolving market.