MIDACO Corporation

MIDACO Corporation, a leading innovator in manufacturing productivity solutions since 1969, will showcase its redesigned Automatic 4-Pallet Changer at IMTS 2024, South Hall Booth #339347.

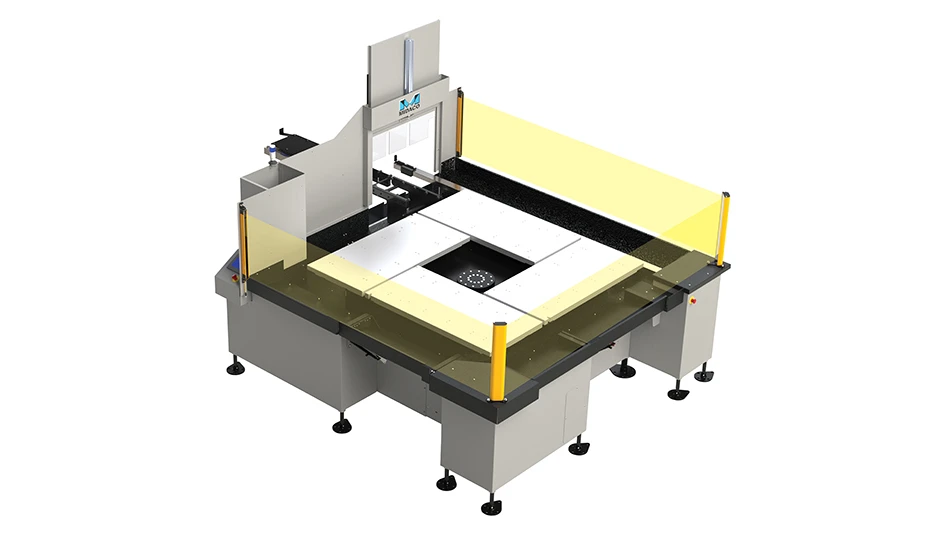

The Automatic 4-Pallet Changer is engineered to revolutionize both high-volume production and low-volume, high-mix multi-setup operations, offering versatility and efficiency. Featuring a single shuttle with four pallets, this system integrates seamlessly with both new and existing VMCs up to a 50” x 25” XY travel, enabling extended periods of unattended machining. This capability significantly increases operator walk-away time and maximizes overall productivity.

Features:

- Versatile pallet sizes and capacities: The system includes four cast aluminum or cast-iron pallets, with sizes ranging from 28” x 15” (711mm x 381mm) and a 500 lbs (226 kg) capacity per pallet, up to 50” x 24” (1270mm x 609mm) with a 2,000 lbs (908kg) capacity per pallet.

- 360-degree rotating shuttle: The pallet carousel allows convenient access to all four pallets from two flip-panel stations. Easily load heavy parts using a crane or robot without any overhead obstruction, even during machine operation.

- Automatic pallet transfer: Upon completion of a job cycle, the pallets rotate automatically on the shuttle carousel, and the servo drive seamlessly transfers the next pallet onto the cast-iron receiver mounted directly on the VMC table. Precision ground steel rails and hardened locating pins/bushings ensure repeatability within +/- 0.0001” (0.0025mm).

- Enhanced safety and integration: This redesigned system includes three-sided safety guarding with a Pilz light curtain. The control panel is fully integrated with the VMC via M-codes, ensuring seamless operation.

Additionally, MIDACO offers a “Dual Automatic 4-Pallet Changer” configuration. This setup features a 4-pallet shuttle mounted on both the left and right sides of the VMC, providing eight fully loaded table setups and enabling continuous, unattended machining for multiple operations.

MIDACO’s mission is to deliver solutions that eliminate idle time and keep machines running efficiently, ultimately driving productivity and profitability for manufacturers.