The Minuteman Series of Teflon composite bearings from LM76 are ideal for applications that involve linear, rotary, and/or oscillating motion. The self-lubricating Minuteman Series composite bearings can handle 10 times the load, has a very low coefficient of friction, dampen vibrations, tolerates shock, and are lower in cost than that of conventional linear ball bearings. These composite bearings can be submerged, washed down with water, high pressure steam, or chemicals, and can operate in harsh, abrasive, and contaminated environments.

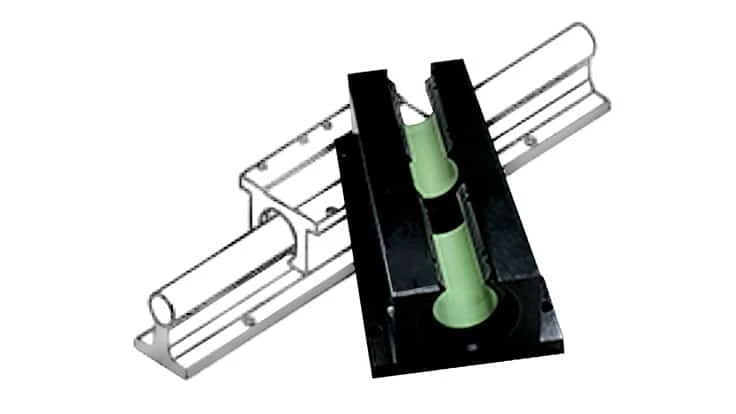

Designers specifying a Minuteman M-SRBT twin pillow block linear rail assemblies can select from seven different shaft sizes from 0.500 of in. to 2.000 in. of either RC60 case hardened steel or 303 stainless steel rail guides in lengths to 12 feet.

As composite bearings are in 100% contact with the shaft there is no place for contaminates to collect and these bearing will not score aluminum shafting.

LM76 manufactures a broad variety of bearings and shafting that can easily be integrated into new and existing applications. The bearing options include Self-lubricating FDA & USDA compliant Teflon composite bearings in a 304 stainless steel shell, and lower cost bearings with a ceramic coated shell and FDA & USDA compliant liner. Bearings are available in closed and open configurations and are drop-in replacements for all inch sized linear ball bearings. Shafting options include Solid and hollow class L 304 stainless steel, and ceramic coated aluminum shafts in lengths to 12 feet. FDA & USDA compliant, shafting features: Excellent corrosion and chemical resistance, custom machining to print, pre-drilling and assembly.