Noblesville, Indiana - Focusing on the replacement of cam-controlled multi-spindle lathes up to 22 mm bar diameter, the new extended version Index MS16 Plus of the MultiLine series is a modular design, 6-spindle CNC multi-spindle lathe. In each work spindle position, the machine can simultaneously accomplish two or more operations, dropping complete parts in very short cycles. It will be demonstrated by Index at IMTS.

According to Index engineers, it is intended to replace the widely used but costly to set up fast cam-controlled multi-spindle lathes that still dominate the market when it comes to machining workpieces of simple to moderate complexity.

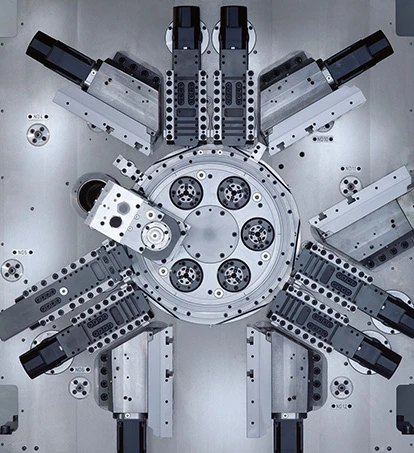

The Index MS16 Plus combines the speed of a cam-controlled machine with the flexibility of CNC technology, yet is extremely compact (1,300 mm width), requiring no more space than current cam-controlled multi-spindle machines. In addition, the MS16 Plus offers exceptional ease of setup and more versatile machining options compared to cam-controlled machines. To keep up with the speed and efficiency of cam-controlled multi-spindle lathes for small parts up to 22 mm diameter, the Index engineers added a number of innovations to the multitasking MS16 Plus.

Infinitely variable speed control of the work spindles

The MS16 Plus makes use of maintenance-free and powerful hollow-shaft motor technology in all work spindles and the optimum selection of cutting data via the CNC program. The six high-torque work spindles with a drive power of 8.7 kW per spindle, which are cooled on demand by the fluid-cooling system proven in the MultiLine series, run in a fluid-cooled spindle drum that is precisely locked through a three-part Hirth coupling after each indexing operation. Thermal growth of the spindle carrier is minimized and the spindle bearing temperature is kept at a low level, which benefits the service life and leads to optimum thermal stability.

Multiple simultaneous machining with grooving or boring and cross-slide

The grooving or boring slides and cross-slides are arranged in a v-shape around each work spindle, allowing trouble-free use of several tools at the same time. The machining type is determined by the tool holder. All operations (external – external, internal – external, stationary – live, and live – live) can be freely defined in almost any spindle position.

Extremely fast spindle stop and cutting off without stroke extender

For rear end machining, the MS16 Plus is equipped with a synchronous spindle driven by a hollow-shaft motor allowing speeds up to 10,000 rpm and which can move 140 mm in Z at 30 m/min to engage several rear end machining tools on the NC cutoff slide with the X- and Z-axis in succession more quickly.

Source: Index Corp.