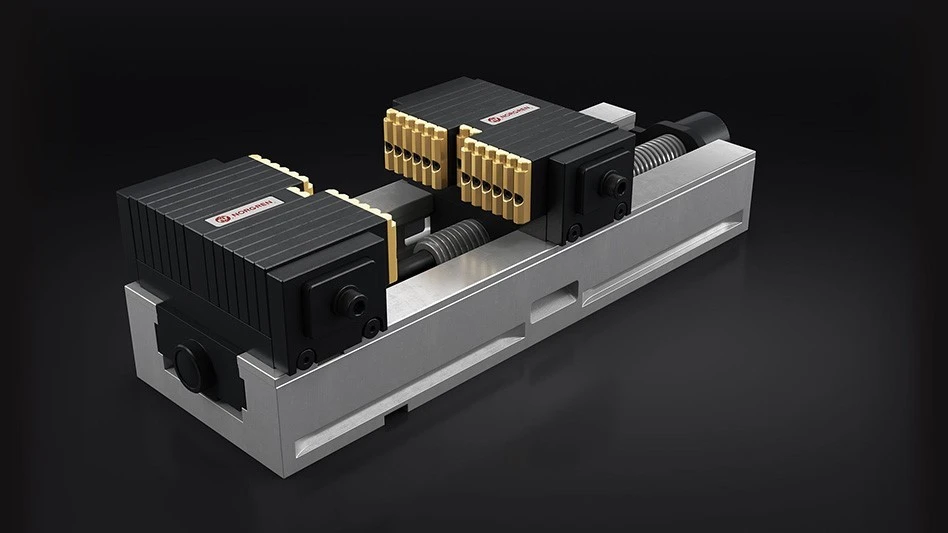

ADAPTIX rapidly adjusts to powerfully grip the most challenging of pieces. Innovative technology ensures repeatability and precision are maintained throughout the machining process, resulting in more uptime and faster changeovers. Unique shapes can be quickly setup and held for high mix, low volume orders. Its ease of configuration and interchangeable pin tips mean machine operators can radically reduce set up and changeover times and their associated labor costs.

As well as the opportunity to investigate the revolutionary ADAPTIX in action, visitors to the Norgren [Workholding] booth can see the wide range of supporting system components such as tips and studs, which enable the product to adapt clamping forces and grip dependent on the material. Norgren’s team of expert application engineers will be on-hand to demonstrate ADAPTIX and to answer technical questions.

Rachel Short, managing director, ADAPTIX says: “We are delighted to present Norgren’s revolutionary ADAPTIX at IMTS. It delivers game-changing time and saving benefits for the CNC market by eliminating the need for an extensive inventory and the provision of ultra-quick new part shape adjustment to aid production efficiency objectives. With built-in flexibility thanks to an array of interchangeable pin tips and a guaranteed performance level for clamping forces, users can add it to their tool portfolio with confidence.”