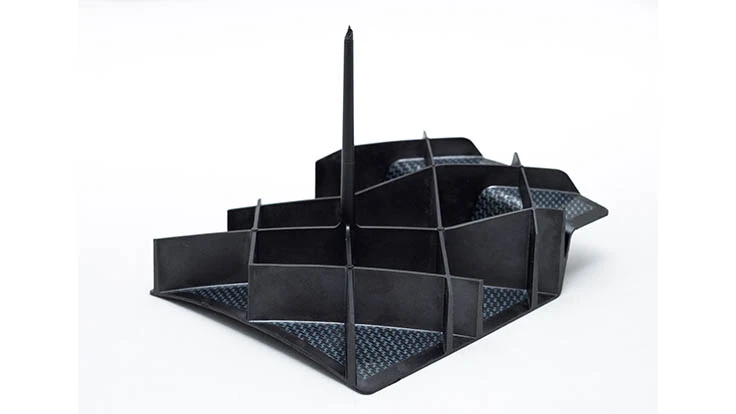

Aerospace grid stiffened demonstration panel - thermoplastic composite using Victrex PAEK-based solutions.

The ThermoPlastic composites Research Center (TPRC), Enschede, The Netherlands, has a new Tier 1 member: Victrex, which recently introduced the Victrex AE250 composite family based on polyaryletherketone (PAEK) polymer. Planned joint activities will concentrate on the acceleration and proliferation of new technologies with the aim of addressing industry needs regarding costs, speed of manufacturing, and assembly of aircraft components.

TPRC has an extensive thermoplastic (TP) processing knowledge, Victrex has in-depth expertise in PAEK materials and applications in combination with a new hybrid molding technology. As a Tier 1 member, Victrex will work alongside other Tier 1 and Tier 2 members, such as Boeing, Daher, Dedienne Aerospace, TenCate, and Vaupell | SB aero.

With the design and manufacture of an advanced demonstration part, the TPRC earlier this year presented the results of a collaborative project of its members on the over-molding of thermoplastic composites. The part features a typical grid stiffened panel that can be found in large numbers in aerostructure applications, made of Victrex PAEK material solutions and is currently among the finalists for the prestigious CAMX Combined Strength Award 2017. The winners will be announced during the CAMX, the Composites and Advanced Materials Expo in Orlando, Florida, Sept. 11-14, 2017.

Tim Herr, aerospace director at Victrex, says, “We will be able to further develop the hybrid molding materials and process technologies with the aim of providing engineers with the development tools required for the design and manufacturing of aircraft components. Refining this technology should help to enable this capability in aerospace supply chains.”

“Victrex joining the TPRC as a Tier 1 member demonstrates the company´s dedication to driving the adoption of new technologies that will open additional opportunities for the aerospace industry. In addition, it represents an appropriate step towards our integrated approach to component design, from raw material, through design and manufacturing and on to mass production,” said Harald Heerink, general manager at TPRC.

Latest from Aerospace Manufacturing and Design

- AviLease orders up to 30 Boeing 737 MAX jets

- 256-piece general maintenance tool kit

- JetZero all-wing airplane demonstrator achieves milestones

- Cermet indexable inserts for medium turning operations

- Trelleborg acquires Aero-Plastics

- Industrial automation products, enclosed encoders

- #61 - Manufacturing Matters: CMMC roll out: When do I need to comply?

- AIX shows aircraft interiors are a strategic priority for global airlines