Toray Industries Inc.

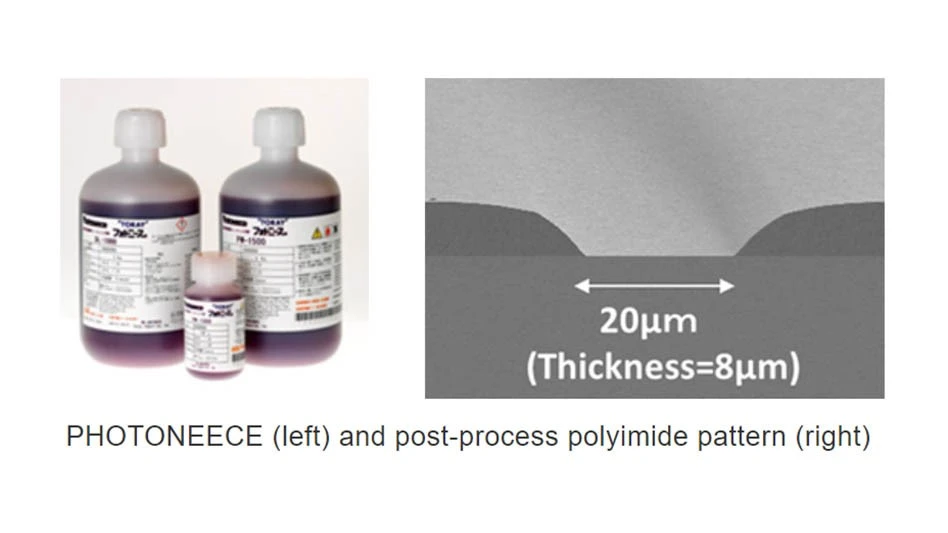

Toray Industries Inc. has developed a new version of its PHOTONEECE photosensitive polyimide coating material*. This modified material employs technology that is free of N-Methyl-2-pyrrolidone (NMP) to lower the potential environmental impacts of that organic compound. The company has established a mass-production system for this new offering, and will launch full-fledged sales, primarily for power semiconductor applications.

Major semiconductor device innovations have fueled the dramatic proliferations of electric vehicles, 5G communications, artificial intelligence, the metaverse, and other advanced technology platforms. The protective insulating films of these devices are predominantly polyimide materials, which safeguard them from manufacturing process and other heat.

Recent years have seen efforts in Europe and the United States to regulate the use of NMP, which serves as a polyimide material solvent. This is because of a growing desire to care for the environment.

Such moves prompted Toray to leverage the functional polyimide design technology it has amassed through the years in creating a technology to synthesize polyimide with NMP alternatives. It can thus provide materials without NMP (below the detection limit of 5ppm).

The outstanding heat resistance and insulation performance of Toray’s new PHOTONEECE make it particularly suitable for power semiconductors, whose manufacturing process requires a lot of heat. These devices also run on much higher voltages than regular semiconductors.

Power semiconductors also have applications that require particularly high voltages, such as large electric vehicles, trains, and electric power stations. For these applications, polyimide films must be especially thick. Despite these challenges, Toray was able to develop an NMP-free photosensitive polyimide material that enables the same high-fidelity pattern processing as conventional counterparts even with films thicker than 15µm, which is more than double the thickness of those counterparts, by applying a technology that enhances light transparency.

The company’s new material is highly adhesive to silicon, copper, and other base materials in contact with the insulating protective film and sample evaluation is currently underway at a major power semiconductor manufacturer.

The Japan Ministry of Economy, Trade, and Industry's "Supply Chain Enhancement FDI Promotion Program" will partially subsidize manufacturing facilities for new materials.

* Note: A photosensitive polyimide changes its solubility in an aqueous alkali or organic solvent developing solution upon light irradiation and can form patterns through the development process. The type in which the exposed area dissolves is positive. The type in which the exposed area becomes insoluble is negative.

Latest from Aerospace Manufacturing and Design

- Malaysia Aviation Group orders 20 more Airbus A330neo widebodies

- More displacement from space-tested piezo actuators

- Textron Aviation to bring its largest-ever lineup to 2025 EAA AirVenture

- Qualified materials for 3D-printing mission-critical applications

- #69 Manufacturing Matters - Shopfloor Connectivity Roundtable with Renishaw and SMW Autoblok

- Demystifying Controlled Unclassified Information (CUI)

- Simplify your shop floor operations while ensuring quality parts

- Happy Independence Day - July 4th