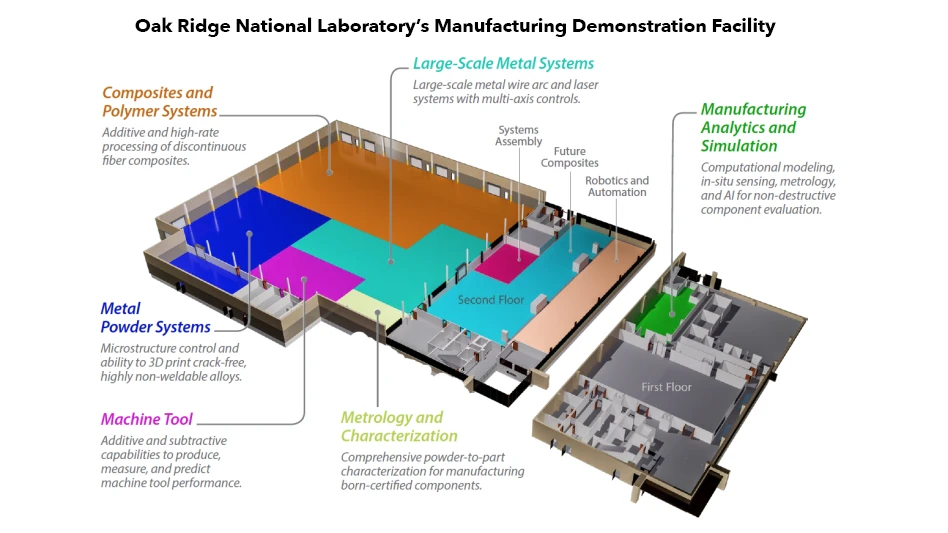

Courtesy Oak Ridge National Laboratory

Wichita, Kansas-based Spirit AeroSystems Inc. is partnering with the Oak Ridge National Laboratory (ORNL) Manufacturing Demonstration Facility in Knoxville, Tennessee, which is managed by University of Tennessee Battelle, for the development of applications in hypersonic travel and aircraft of tomorrow.

Spirit and ORNL will jointly focus on scalable, efficient manufacturing of advanced material solutions in the commercial, defense, and space aerostructure markets. They will collaboratively explore advances in high temperature in-situ process monitoring techniques and predictive modeling capability for microstructure-based performance and certification of carbon and ceramic composites as well as additively manufactured alloys. In addition, research teams will study various processing techniques for materials that can withstand extreme heat and harsh environments, including the scaling up of a thermal protection system for aerospace platforms.

“Efficiently producing these advanced material types will advance American manufacturing and do so with lower emissions through the Department of Energy’s Industrial Demonstration Program, said Dr. Sean Black, Spirit AeroSystems senior vice president, chief technology officer and chief engineer. “With the right manufacturing techniques, machines, and tools capable of reaching a high rate on products, paired with the right approach to manufacture advanced materials and a relentless drive to optimize, means success in designing and modeling fully integrated commercial and defense aerospace systems.”

The ORNL Manufacturing Demonstration Facility is the nation’s largest advanced manufacturing research facility focusing on manufacturing analysis and simulation, composites and polymer systems, metal powder systems, metrology and characterization, machine tooling, large-scale metal systems, and robotics and automation. The Manufacturing Demonstration Facility, in partnership with industry, develops and demonstrates the latest advancements in new manufacturing systems, materials, and processes.

Latest from Aerospace Manufacturing and Design

- Solar Atmospheres of Western PA gets Pratt & Whitney approval

- Tungaloy’s TungBoreMini drilling and turning tool

- 3 Questions with an Expert: Mitutoyo

- Optimize your manufacturing applications with the right metrology tools

- Navigating today’s supply chain

- Piper Aircraft Inc. achieves AS9100 Certification

- Kyocera SGS' KGZ precision cut-off solutions

- Bridging the Skills Gap: A Solution for Today’s Labor Shortage