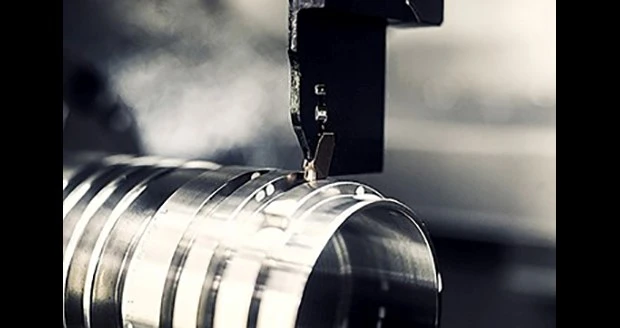

Fair Lawn, New Jersey – Sandvik Coromant officials offer a new white paper on “Parting & Grooving: How to achieve greater performance, quality, and tool life in the 21st century.”

Production engineers faced with overcoming the challenges of parting and grooving need reliable tools capable of delivering world-class performance in terms of productivity, quality, and tool life. To ensure that market demand is met, Sandvik Coromant has invested many decades and considerable resources in continuous research, development, and testing of parting and grooving technologies. Conducted in close cooperation with customers, each technology is developed to bring direct benefits to the end user. This white paper will share some of the knowledge gained throughout the years and serves as a guide to the latest cutting-edge technology and best practices for parting and grooving.

Source: Sandvik Coromant

Latest from Aerospace Manufacturing and Design

- 2024 Favorites: #5 Article – Solving workforce issues with digital transformation

- 2024 Favorites: #5 News – GE Aerospace is investing in manufacturing

- 2024 Favorites: #6 Article – Mastering complex precision machined parts

- 2024 Favorites: #6 News – Boeing to acquire Spirit AeroSystems in $8.3B deal

- Season's greetings

- 2024 Favorites: #7 Article – Deep drawing aerospace components

- 2024 Favorites: #7 News – GKN Aerospace completes sale of St. Louis facility to Boeing

- 2024 Favorites: #8 Article – Beyond uptime