GIE Media’s Manufacturing Group

About the presentation

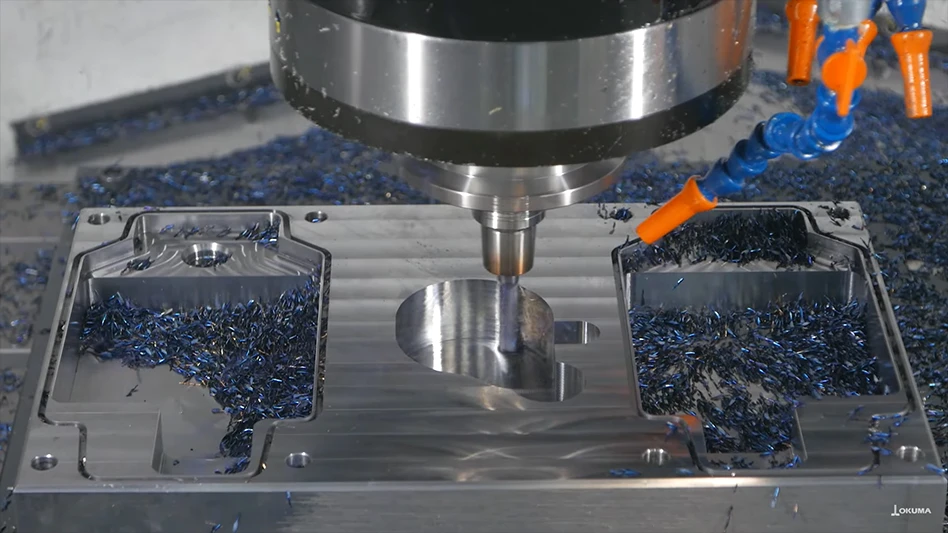

The cost of any metalworking fluid is a small fraction of the total investment into a manufacturing process. However, it has a large impact because it touches everything in the shop. The idea that this minor player – around 0.5% of the production cost – influences the success of the other 99.5% is called the “leverage effect” of metalworking fluids.

In this session, operations and maintenance managers will learn:

1. The impact of the right metalworking fluid on major cost centers in the shop

2. How to use coolant to extend tool life, increase cutting speeds, and gain process stability

3. Examples of improvement goals from other shops, from productivity to health and safety

4. How to reduce hours on unpleasant maintenance tasks and protect your valuable CNC machines

Registration

Powered by AMT and managed by GIE Media, The IMTS 2022 Conference features 69 different sessions you won’t want to miss so register today. Focused on a range of topics that include process innovation, plant operations, quality/inspection, and automation, The IMTS 2022 Conference addresses improving productivity; improving part quality; and developing a stable, competent workforce to lower the cost of manufacturing in the United States and create new levels of market demand.

Meet your presenter

Chris Porsch is the sales director for the Midwest and Western regions of Blaser Swisslube. He has a background in Chemistry and a Bachelor’s degree in Business. He developed deep knowledge of metalworking fluids and their applications over the past 8 years, and he is driven to share his expertise to help Blaser Swisslube customers improve processes and reduce manufacturing costs.

About the company

For more than eight decades, Blaser Swisslube has been reputed for human-compatible and environment-considerate products. Our customers not only want cutting fluids, but also need a competent partner to help optimize their machining processes. With our committed team, we provide this partnership. More than 80 specialists at our headquarters R&D and technology center are constantly developing better solutions for tomorrow, including innovations such as DNA analysis of cutting fluids and product trials on the latest CNC centers and machine tools.

Latest from Aerospace Manufacturing and Design

- Honeywell, NXP expand aviation technology partnership

- ETCO connectors and terminals for drones

- Vertical Aerospace starts 2025 with piloted thrustborne milestone

- Seco's digital boring heads

- America Makes announces winners of $2.1M project call

- HEULE's GH-K Tool

- Mastercam acquires FASTech

- Amada Weld Tech's AWS3 Pneumatic Active Welding System