High-speed machining (in excess of 20,000rpm) is often used in aerospace when machining exotic alloys and hard metals such as titanium.

At these speeds, precise and secure seating of tapered toolholders in the spindle becomes even more critical. So much so, that failing to pay attention to this single detail can lead to decreased productivity, less precise machining, reduced tool life, and damaged workpieces.

Often overlooked, even ignored, are poorly designed retention knobs that – when tightened – create a bulge in the small end of the taper that prevents full contact and proper seating in the spindle.

Despite widespread evidence of uneven wear patterns and simple touch-off tests that immediately identify it as a widespread issue, the industry has largely ignored this aspect of machining and, unwittingly, are paying a price for it.

The flaw in the system

Shanks of tapered toolholders are ground to a fine finish within very precise, established tolerances, and are also threaded at the narrow end to accept a retention knob. The knob engages with the drawbar, which exerts a pull force that holds the toolholder firmly in the spindle.

The problem is poorly designed, traditional retention knobs – a less-than-$30 part – when tightened, create a bulge in the taper that prevents proper seating in the spindle. Once this expansion occurs, the toolholder will not pull fully into the spindle and so cannot contact upward of 70% of its surface.

The results are manifest in a wide range of CNC milling issues often attributed to other causes: vibration and chatter, poor tolerances, non-repeatability, poor finishes, shortened tool life, excessive spindle wear, run-out, and shallow depths of cuts.

“A lot of aerospace work is really tight tolerance,” says Rex Ausbun at Cling’s Aerospace, a Tempe, Arizona-based company that specializes in complex 4- and 5-axis precision-machined parts. “When you see chatter or vibration, you know there is an issue with the toolholder.”

According to Ausbun, who is responsible for purchasing all the inserts, tools, and other machining accessories for Cling’s Aerospace, “with a tapered toolholder, you want to marry it as tight as possible to the spindle to get as much contact across the entire taper as possible. That way, you are not just hitting at the top of the angle.”

Retention knobs accomplish this; however, Ausbun says that newer CNC milling machines exert significantly more drawbar pressure on the knobs than in the past. This is compounded by the fact that most retention knob manufacturers provide little information on the proper torque required, a factor that can lead to the improper seating already described.

As a result, Ausbun says several of the retention knobs literally pulled apart during operations.

“As CNC machines drawbar tension continues to increase, it puts so much pressure on the weakest link, the retention knob, that it’s bound to come apart. It’s a significant issue, because if the retention knob comes apart while the machine is running, it could cause considerable damage.” Ausbun notes, “You are talking spindles that cost $10,000 to $14,000 a piece, not to mention the downtime. That’s a lot of money.”

High-torque retention knobs

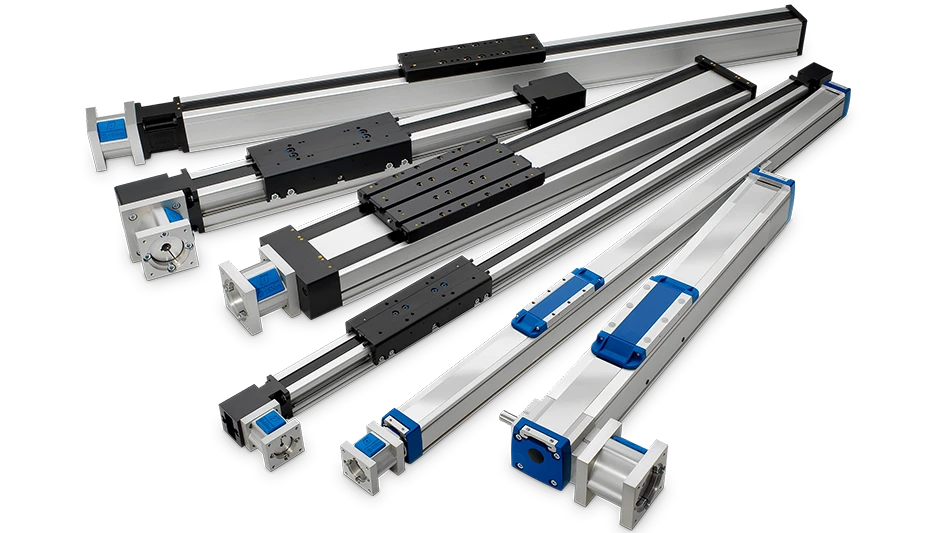

To find a solution, Ausbun discovered JM Performance Products Inc. (JMPP) searching online. In 2009, the company introduced its High Torque retention knob. Invented by the company’s founder, John Stoneback, the product works with all existing toolholders including BT, DIN, ISO, and CAT toolholders from 30 taper to 60 taper.

The High Torque retention knob is longer to reach deeper into the threaded bore of the toolholder. As a result, all thread engagement occurs on the toolholder where there is a thicker cross-section of material to resist deformation.

It also includes a precision pilot to increase rigidity and is balanced by design. Since over-tightening of the High Torque retention knobs can still create a bulge, the company provides specifically calculated torque specs based on drawbar pressure.

By combining the High Torque retention knob with the correct torque, spindle contact with the taper is improved to close to 100% every time.

“When you start checking out different manufacturers as to what they recommend for torque specs on the retention knobs, everyone seems to have a different opinion,” Ausbun says. “I thought it was pretty impressive that [JMPP] went the extra mile and put a lot of research into determining the ideal torque.”

Tool life

By increasing toolholder rigidity at higher rpms, the High Torque retention knob can also increase tool life.

Aerospace manufacturing can take a toll on the carbide cutting tools used when machining exotic alloys and hard metals, so cutting tools must be changed more frequently as they dull or break.

“In aerospace, every shop is trying to machine parts faster and aggressively remove more stock, just to stay competitive,” Ausbun says. “This just puts more pressure on the tool.”

With higher-end technical carbide inserts, the cost of tool replacement and lost production time due to frequent changeover can add up quickly.

“Since we changed to the High Torque Retention Knobs, we are not going through inserts like we used to, and we haven’t had any more issues with retention knobs pulling apart,” Ausbun adds. “I’m also not seeing any distortion in the toolholder taper either.”

As a result, Ausbun estimates that tool costs have been reduced by as much as 20%.

Try a touch-off test

For those that are not entirely convinced that improper seating of tapered toolholders is even a problem, JMPP suggests a simple 6-step touch-off test. More sophisticated measurement of toolholder expansion (bulge) can also be taken using a taper shank test fixture.

Source: JM Performance Products

Latest from Aerospace Manufacturing and Design

- Electra reaches 2,200 pre-orders for its Ultra Short aircraft

- Heule's DL2 tooling for deburring of small bores

- Ralliant to establish global headquarters in North Carolina

- Philatron MIL-DTL-3432 military cables

- Beyond Aero refines its hydrogen-electric light jet

- Americase's advanced protective solutions

- Social media - what are your thoughts

- GE Aerospace secures Air Force engine contract