Airborne

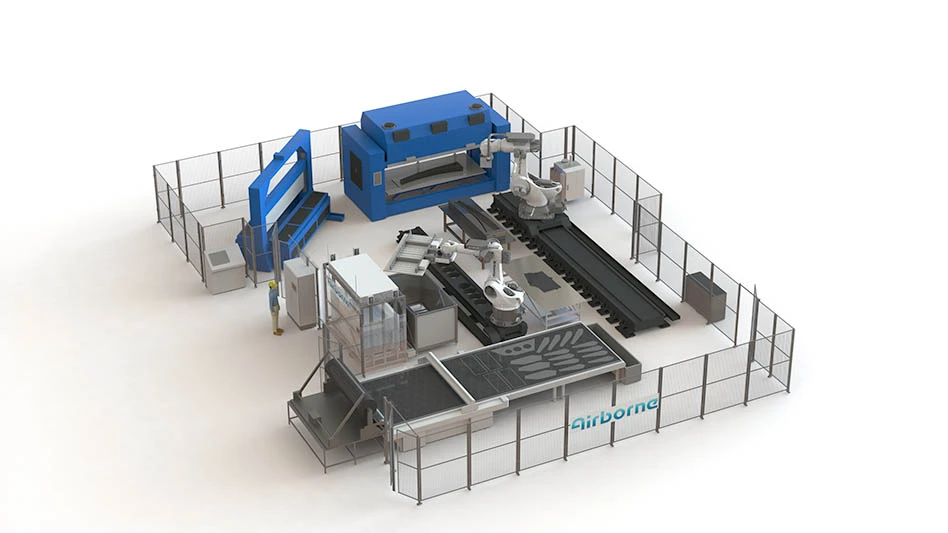

GKN has selected Airborne to supply a fully automated preforming line to the Global Technology Centre, Bristol, UK. The system will integrate an automated ply placement (APP) cell by Airborne, automated preform trimming by Accudyne Systems, a ply cutter from Assyst Bullmer, and a hot drape former by PAC Group.

The system will transform broad goods such as woven or non-crimp fabric (NCF) materials into 3D preforms suitable for resin transfer molding (RTM). Cut shapes can be optionally stored in Airborne’s buffer enabling out-of-sequence nesting, minimizing material waste and improving cost and sustainability. Plies will be assessed using a vision system and then via pick-and-weld assembled into 2D tailored blank preforms. These will be 3D formed by the hot drape former and then finally trimmed to shape on the trimming cell.

Each sub-system will be integrated by Airborne into its automated programming software platform. Each device can be operated stand-alone, however in automated mode the system will translate design and process input into individual controls and robot code without the need for programming. The system will generate instructions on the fly enabling flexible manufacturing.

The system will initially be deployed to fulfil objectives of the Aerospace and Automotive Supply Chain Enabled Development (ASCEND) project, a UK industry consortium GKN Aerospace is leading to develop and accelerate composite material and process technologies for the next generation of energy efficient aircraft and future mobility. The £40M ($50.8m) consortium, funded by a £20.0M ($25.4m) commitment from industry and a £19.6M ($24.9m) commitment from the UK Government, will focus on greater adoption of composite technologies today, the industrialization of new technologies, as well as accelerating aerospace production rates to meet future high-volume requirements. The collaboration will help develop technologies from across the UK supply-chain to develop the advanced materials and automation equipment required to manufacture lightweight structures for the sustainable air mobility, aerospace, and automotive industries. The new Automated Preforming Cell from Airborne will provide the capability to manufacture next generation components for the aerospace market.

Joe Summers, commercial director of Airborne and managing director of Airborne UK said, “This major commitment from GKN Aerospace to Airborne’s technology further supports our goal to offer flexible automation solutions and workflow automation enabling higher rate manufacturing of composite structures.”

Latest from Aerospace Manufacturing and Design

- Taiwan’s China Airlines orders Boeing 777X passenger, freighter jets

- Reamer re-tipping extends life of legacy tooling

- Revitalizing the Defense Maritime Industrial Base with Blue Forge Alliance

- Safran Defense & Space opens US defense HQ

- Two miniature absolute encoders join US Digital’s lineup

- Lockheed Martin completes Orion for Artemis II

- Cylinder CMMs for complex symmetrical workpieces

- University of Oklahoma research fuels UAS development