GKN Aerospace

GKN Aerospace will lead a UK collaboration program, called H2GEAR, to develop the company’s first hydrogen propulsion system for sub-regional aircraft. Hydrogen is expected to play a key role in the decarbonization strategy of aviation as it can power aircraft efficiently, leaving water as the only by-product.

H2GEAR puts GKN Aerospace at the heart of the technology developments needed for the future of more sustainable aviation. The technology will first focus on significantly improving sub-regional aircraft hydrogen powered performance, in turn enabling applications on larger aircraft and longer journeys. The program is supported by $37 million of Aerospace Technology Institute (ATI) funding, matched by GKN Aerospace and its industrial partners.

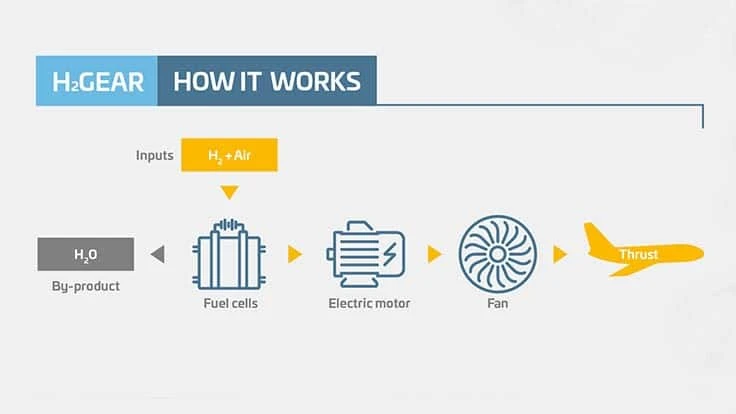

In the H2GEAR system, liquid hydrogen is converted to electricity within a fuel cell system to efficiently power the aircraft. This would create a new generation of clean air travel, eliminating harmful CO2 emissions.

H2GEAR will reinforce the UK’s position at the forefront of aerospace technology research and development. GKN Aerospace will collaborate with Intelligent Energy, Aeristech, Newcastle University, The University of Manchester, and University of Birmingham, throughout the program, aiming to create more than 3,000 jobs in the next decade. The program will be delivered from GKN Aerospace’s Global Technology Centre in Bristol, UK, the company’s new $44 million collaborative space for research and development.

GKN Aerospace’s Chief Technology Officer Russ Dunn said, “Hydrogen-powered aircraft offer a clear route to keep the world connected, with dramatically cleaner skies. The UK is at the forefront of this technology, and the H2GEAR project is an example of industry, academia, and government collaboration at its best. Working with our partners, and made possible by government investment, GKN Aerospace will develop and industrialize the breakthrough technology to fly aircraft with zero CO2 emissions by the mid-2020s. This will not only create thousands of jobs, but it will keep the UK at the forefront of the next generation of cleaner air travel for decades to come.”

GKN Aerospace will use its long-term experience and in-depth knowledge of electrical power systems and propulsion technology to accelerate the development of technology. The entry-into- service of the first hydrogen-powered aircraft could be as early as 2026.

H2GEAR partners:

GKN Aerospace is a multi-technology tier 1 aerospace supplier. It develops, builds, and supplies aerostructures, engine systems, transparencies and wiring systems for use in aircraft ranging from helicopters and business jets to the most used single aisle aircraft and the largest passenger planes in the world. GKN Aerospace operates in 14 countries at 48 manufacturing locations employing approximately 17,000 people.

Intelligent Energy (IE) will create new and innovative IP, know-how, skills and capabilities in the field of lightweight fuel-cell stacks (using new materials, coatings and processes) and systems configured for zero emission flight propulsion requirements. These will be exploited through development by IE, and IE's supply chain, of new fuel cell products and services in aviation application.

Aeristech was founded in 2006 and is a leading designer of advanced electric motor and control systems, winning the Queen's Award for Enterprise: Innovation in 2020. Aeristech’s technology enables it to manufacture the world’s fastest accelerating and most power dense permanent magnet variable speed electric motors for applications where efficiency, power density, and speed are essential. Its Leamington Spa headquarters feature laboratories, pilot production and test facilities.

As a member of the Russell Group of research-intensive universities in the UK, Newcastle University has a world-class reputation for research excellence in the fields of medicine, science and engineering, social sciences, and the humanities.

The Research Excellence Framework 2014 (REF) placed Newcastle University 16th in the UK for Research Power and the vast majority of our research was assessed to be world-leading or internationally excellent.

The University of Manchester has a worldwide reputation for pioneering research in electrical networks and electrification of transport. The ambition of this project is to develop cryogenic technologies to create new electric drive concepts enabling power dense, highly efficient zero emission propulsion for aerospace.

The Centre for Fuel Cell and Hydrogen Research at the University of Birmingham will work on the future aviation fuel cell stack concept. The future stack will be based on the Novel Intermediate Temperature Polymer Electrolyte Fuel Cell (IT-PEFC) technology being developed at University of Birmingham. The IT-PEFC stack will offer an increase in power density, improved performance, and simplified balance of plant.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.Latest from Aerospace Manufacturing and Design

- Lockheed Martin, NASA X-59 takes flight

- Claw jaws for maximum clamping force

- #53 Lunch + Learn Podcast with Iscar

- PI moves into new US headquarters

- Indexable thread milling grade with PVD aluminum oxide coating

- Falcon Aviation Services orders 50 eVTOL aircraft from AutoFlight

- Finned rollers for firm, safe, efficient parts handling

- Vietjet finalizes order for 100 Airbus A321neo aircraft