Santa Clara, California – Arevo Labs has introduced a scalable robot-based additive manufacturing (RAM) platform for fabricating 3D printed composite parts.

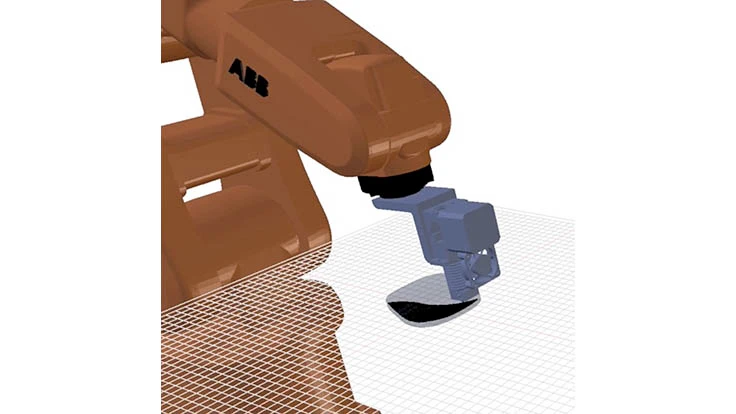

The solution consists of a standard commercially available robot, composite deposition end-effector hardware, and a comprehensive software suite. Arevo’s solution is tailored to ABB’s smallest 6-axis robot, the IRB 120, though the scalable software can support larger ABB robot models and sizes. The additive end-effector hardware consists of a deposition head with advanced thermal management technology for processing high-performance carbon-fiber reinforced thermoplastic filaments.

Arevo’s software suite includes:

- CAM software to convert CAD models to a set of additive deposition instructions for the robot. Software is capable of six degrees of freedom, enabling true 3D additive manufacturing.

- A precise kinematics simulator that interprets deposition instructions to validate and optimize part construction.

Arevo Labs’ RAM platform interfaces with ABB’s RobotStudio programming and simulation software to ease tool path generation from CAD files.

The platform’s multi-axis toolpaths enable, for the first time, production quality parts constructed with true 3D surfaces in variable orientations. The resulting parts have strength and aesthetics superior to those made with conventional Cartesian-based additive manufacturing equipment and software.

In addition to expanded design possibilities, the Arevo Labs’ Robotic Additive Manufacturing Platform maximizes size scalability and production efficiency. Key enabling technologies include automation and secondary process integration within manufacturing work cells. Depending upon the size of the robot, the part build envelope is scalable from 1,000mm3 to 8m3.

“We are excited to be the first to develop a robot based additive manufacturing platform optimized for composite parts,” said Hemant Bheda, CEO and founder of Arevo Labs. “Unencumbered by the constraints of conventional Cartesian systems, this platform is the dawn of the additive manufacturing work cell for the aerospace and defense factory-of-the-future.”

“Our ABB IRB120 robot is perfectly suited for the Additive Manufacturing Platform, offering the high precision and repeatability required for 3D printed parts for end-use applications. We are glad to see ABB’s robot performance and capabilities being fully utilized with Arevo Labs’ software in printing true 3D surfaces," said Nicolas De Keijser, new applications business line manager at ABB.

Source: Arevo Labs

Latest from Aerospace Manufacturing and Design

- Avio USA, ACMI Properties partner on rocket motor production

- norelem's modular clamping systems for metrology

- IMTS 2024 Booth Tour: Behringer Saws

- Toray Advanced Composites acquires Gordon Plastics

- Dillon Manufacturing's 3-jaw chucks

- IMTS 2024 Booth Tour: Belmont Equipment & Technologies

- Boeing strike ends after more than 7 weeks

- Siemens acquires Altair Engineering