Photo credit: Airbus SAS 2022/Hervé Gousse – Master Films

The Airbus Summit 2022 brought together business leaders, partners, and industry experts to exchange ideas and debate the challenges and opportunities of sustainable future flight. The event provided an opportunity for Airbus to reveal numerous initiatives it is undertaking toward zero-emission aircraft.

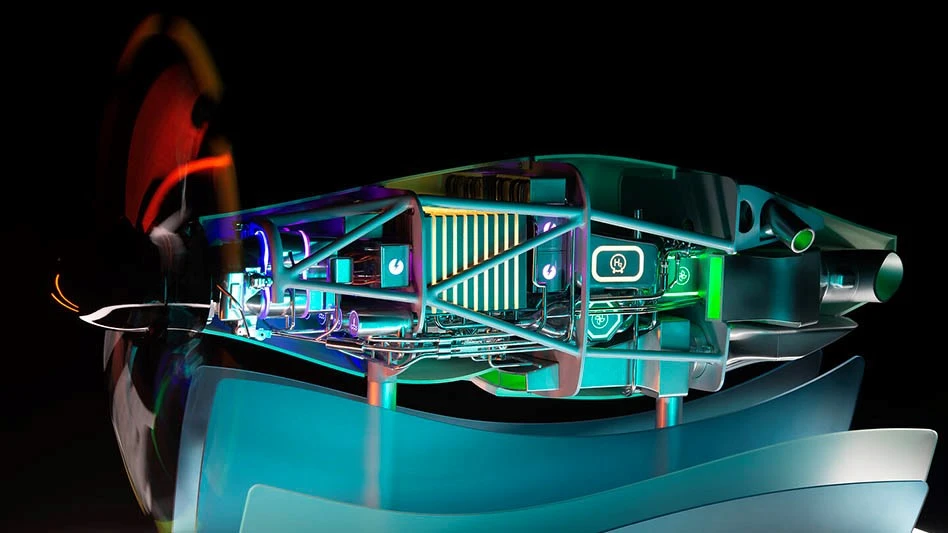

Among the announcements, Airbus revealed it is developing a hydrogen-powered fuel cell engine. The propulsion system is being considered as one of the potential solutions to equip its zero-emission aircraft that will enter service by 2035.

Airbus will start ground and flight testing this fuel cell engine architecture onboard its ZEROe demonstrator aircraft towards the middle of the decade. The A380 MSN1 flight test aircraft for new hydrogen technologies is currently being modified to carry liquid hydrogen tanks and their associated distribution systems.

“Fuel cells are a potential solution to help us achieve our zero-emission ambition and we are focused on developing and testing this technology to understand if it is feasible and viable for a 2035 entry-into-service of a zero-emission aircraft,” said Glenn Llewellyn, VP Zero-Emission Aircraft, Airbus. “At scale, and if the technology targets were achieved, fuel cell engines may be able to power a 100- passenger aircraft with a range of approximately 1,000nm. By continuing to invest in this technology we are giving ourselves additional options that will inform our decisions on the architecture of our future ZEROe aircraft, the development of which we intend to launch in the 2027-2028 timeframe.”

Airbus identified hydrogen as one of the most promising alternatives to power a zero-emission aircraft, because it emits no carbon dioxide when generated from renewable energy, with water being its most significant by-products.

There are two ways hydrogen can be used as a power source for aircraft propulsion. First via hydrogen combustion in a gas turbine, second, by using fuel cells to convert hydrogen into electricity to power a propeller engine. A hydrogen gas turbine can also be coupled with fuel cells instead of batteries in a hybrid-electric architecture.

Because one single fuel cell is only a few millimeters thick and roughly the size of a letter envelope, it doesn’t release much energy. To realize sufficient power levels for use in an aircraft, hundreds of these fuel cells need to be electrically connected in series to form a stack. combined into multiple fuel cell channels. With this modular approach, the megawatt levels of power needed for an electric aircraft are achievable.

Hydrogen fuel cells, especially when stacked together, increase their power output allowing scalability. In addition, an engine powered by hydrogen fuel cells produces zero NOx emissions or contrails, thereby offering additional decarbonization benefits, according to the company.

Airbus has been exploring the possibilities of fuel cell propulsion systems for aviation for some time. In October 2020, Airbus created Aerostack, a joint venture with ElringKlinger, a company with more than 20 years of experience as both a fuel cell systems and component supplier.

Two years after Aerostack was formed, collaborative work is well underway. The first prototype fuel cell stacks are already being evaluated by Airbus in Hamburg, where the teams are designing fuel cell systems, assembling, and testing them.

In December 2020, Airbus presented its pod-concept which included six removable fuel cell propeller propulsion systems.

In other news from the summit, Airbus UpNext, a wholly owned subsidiary of Airbus, and CERN, the European Laboratory for Particle Physics, are launching a project to evaluate how superconductivity can contribute to the decarbonization of future aircraft systems.

Airbus unveiled its DisruptiveLab, a new flying laboratory using an existing H130 helicopter to test technologies destined to improve aircraft performance and to reduce helicopters’ CO2 emissions.

Airbus signed a partnership agreement with HyPort, a joint venture between ENGIE Solutions and the Regional Agency for Energy and Climate in Occitanie (AREC), a leader in the development of green hydrogen in France, to support the development of one of the world’s first low carbon hydrogen production and distribution stations at an airport.

Construction of the hydrogen station at Toulouse-Blagnac airport was completed earlier this year and the production, storage, and distribution systems are currently undergoing final testing. The station which is slated to enter-into service in early 2023 will have a capacity to produce around 400kg of hydrogen per day, providing the possibility to power some 50 ground transportation vehicles.

Airbus and ArianeGroup, a joint venture in space propulsion technologies equally owned by Airbus and Safran, will work together to build the first liquid hydrogen refueling facility for ZEROe aircraft at Toulouse, Blagnac airport. The station will be operational in 2025.

Latest from Aerospace Manufacturing and Design

- Mastering high-temp alloys with Kennametal Inc.

- Boeing to sell portions of digital aviation solutions

- SMW-Autoblok’s KNCS-matic 3-jaw power chuck

- 3 Questions with an Expert with Allied Machine & Engineering

- Electra raises $115M to pioneer Ultra Short aircraft

- Walter’s WT26 partial- and full-profile thread turning inserts

- April Manufacturing Lunch + Learn with Iscar

- April Manufacturing Lunch + Learn with Insaco