The commercial aerospace industry’s ambitious targets to reduce net greenhouse gas emissions 50% by 2050 (from 2005 levels), are not on track. To succeed, airframe and engine manufacturers, suppliers, and companies throughout the value chain must coordinate the sustainability agenda. A collaborative effort will ensure the industry has a say in its own future, rather than having that future shaped by government regulations.

That’s the premise of a new report from Boston Consulting Group, “The Sustainability Opportunity for Aerospace.” The authors contend that although various new technologies and solutions are emerging to increase efficiency and reduce greenhouse gas emissions, they represent only incremental improvements. The industry must take more transformational measures because proactive coordination will lead to faster reductions in CO2 emissions. Moreover, sustainability represents an opportunity for the aerospace industry.

Now is the time for aerospace companies to chart a path to sustainability as they consider pandemic-related restructuring initiatives. During the next 12 to 18 months, the industry should retain emissions-related capabilities and investments as it reconsiders how to manage post-COVID-19 travel demands, remote work, and other immediate challenges.

“Leadership teams will clearly face tough choices regarding what to trim, but sustainability initiatives should not be on the list,” the report’s authors argue.

Companies should consider the full range of collaboration structures, including co-investing with other stakeholders, changing suppliers, and exploring vertical-integration opportunities that prepare them to develop or incorporate carbon-reduction technologies.

One example: forming a consortium of fuel refiners, engine manufacturers, infrastructure developers, and regulators to consider how best to implement sustainable aviation fuels (SAFs) refined from non-petroleum feedstocks. SAFs offer significant emission reductions with existing engine designs. However, to supply enough SAFs to achieve 50% adoption by 2050, production capacity will have to increase 25x.

Another advantage, collaboration can help companies identify new opportunities in adjacent business areas, such as battery manufacturing or hydrogen fuel cells.

“Given that sustainability imperatives are growing in virtually all industries, this approach will allow organizations to expand beyond their current boundaries and potentially develop products and services that address broader decarbonization challenges,” the authors say.

“There’s more to do than just focusing purely on technical investments,” Gonzalo Tobaruela, a BCG project leader, tells AM&D. “Technologies won’t be introduced at scale unless regulations and the overall industry ecosystem support them.”

Companies should work with regulators to establish standards needed to shape the sustainability agenda. A proactive approach will give companies a seat at the table as new standards are established, converting regulation into a source of competitive advantage.

Regulators must create positive incentives as well. Subsidies have promoted change – boosting adoption of electric vehicles (EVs), for example. Similar approaches in the aerospace sector could encourage research and development investments and adoption of new technologies.

Aerospace companies have a choice. They can be passive participants and fall behind the competition. Or they can be proactive, building the right foundations today to seize sustainability’s opportunities in the future. – Eric

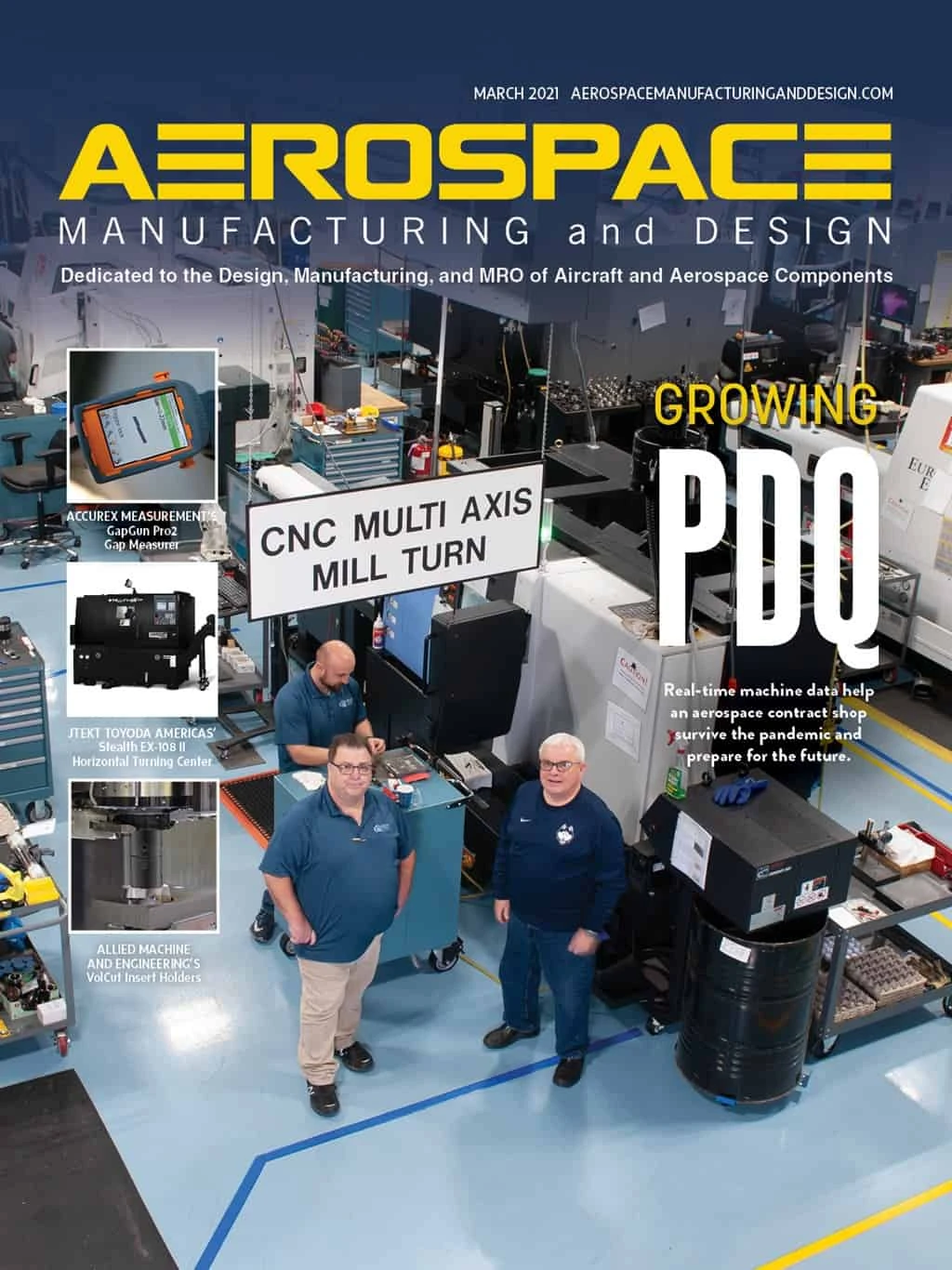

Explore the March 2021 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Piasecki acquires Kaman's KARGO UAV program

- PI Americas’ long-travel XY piezo nanopositioners-scanners

- AAMI project call submission deadline extended to May 12

- Jergens launches cast iron tooling column additions

- Airbus to acquire assets relating to its aircraft production from Spirit AeroSystems

- FANUC America's Cobot and Go web tool

- Chicago Innovation Days 2025: Shaping the future of manufacturing

- High-density DC/DC converters for mission-critical applications