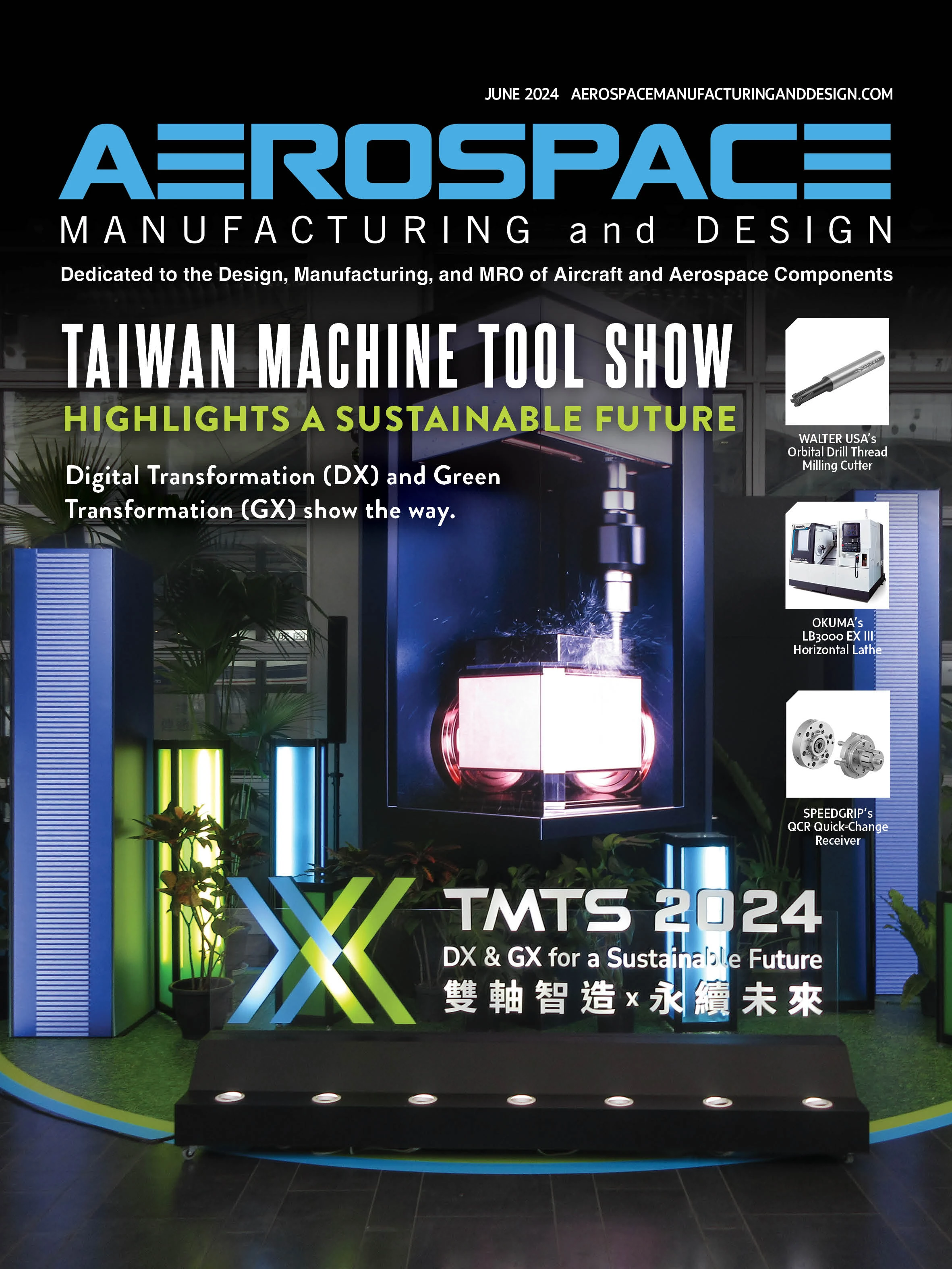

This year’s Taiwan International Machine Tool Show (TMTS 2024) incorporated dual themes of Digital Transformation (DX) and Green Transformation (GX) as the means to achieve a sustainable future. The March event, organized by the Taiwan Machine Tool & Accessory Builders’ Association (TMBA), marked the show’s first appearance in the island’s capital city. The DX and GX themes were interwoven across 10 major elements and 9 thematic exhibition zones in two exhibit halls at the Taipei Nangang Exhibition Center.

Bringing together 26 companies and more than 50 machines, components, and end users digitally, the German Machine Tool Builders’ Association (VDW) and the German Engineering Federation (VDMA) partnered with the organizers to set up the universal machine technology interface (umati). This allowed equipment from different industries to connect on one platform, facilitating data transfer between machine tools, 3D printers, and product management systems.

TMBA Chairman (and YCM Co. GM) Patrick P. Chen remarked at the opening ceremony, “This not only showcases the digital transformation capabilities of Taiwanese companies but also reflects TMBA’s efforts in aligning industry standards with international norms.”

Reducing machine tools’ carbon footprint

TMBA, with more than 800 members, has been actively promoting carbon reduction in the machine tool industry. Chen says, “In 2022, we published Taiwan’s first carbon reduction handbook exclusively for the machine tool industry.”

In 2023, TMBA established Taiwan’s first carbon reduction supply chain for machine tools. This year, it jointly established six major product category rules (PCR), aiming to align with international standards and lay the foundation for establishing a machine tool industry carbon footprint database.

Evidence of the effort was visible in many machine tool exhibitors proclaiming compliance with a suite of International Organization for Standardization (ISO) guidelines, including ISO 14064-1/-2 (greenhouse gases), ISO 14067:2018 (products’ carbon footprint), and the three-part ISO 14955:2017 (design methodology for energy-efficient machine tools, energy measurement, and testing metal-cutting machine tools for energy efficiency).

TMTS also hosted the first Machine Tool Energy Saving Label Evaluation, encouraging the development of energy saving equipment or components to showcase exhibitors’ capabilities in GX. Scoring was based on energy saving improvements, feasibility assessment of energy saving, energy saving benefits, continuous improvement plans, and bonus points for adopting international standards. In all, 28 companies with 49 products participated in the evaluation, resulting in 18 products (including three components) receiving the Golden Energy Saving Label and 29 products receiving the Silver Energy Saving Label. These Circular Economy TNBA labels were prominently displayed at exhibitor booths.

“The products demonstrate the Taiwan machine tool industry’s continuous pursuit of technological innovation and transformational upgrades,” Chen says.

Rounding out the exhibition, a series of forums had domestic and overseas experts sharing insights on DX, GX, talent sustainability, and industry-academia collaboration.

DX, GX for a sustainable future

As presented at TMTS, the DX tenets are:

Smart manufacturing – Automate and digitize production processes through intelligent technology to improve production efficiency, quality.

Data analytics and cloud computing – Apply big data, artificial intelligence (AI), and other technologies to analyze data on production processes and product quality, optimize production processes, or achieve production data management and application through cloud computing.

AIoT – Integrate AI and Internet of Things (IoT) technologies to transform the factors of production – operator, machine, material, method, and environments – into data resources.

Digital twin/Human-machine collaboration – Simulate and optimize production processes through digital twin technology. Apply robotics or AI to achieve human-machine collaboration.

Blockchain technology – Apply to achieve product traceability and quality control, improve reliability and trust of products.

GX consists of:

Smart energy conservation – Improve energy efficiency, reduce energy consumption through energy management systems, automated monitoring systems. Reduce carbon emissions using environmentally friendly energy sources to improve production lines’ energy efficiency.

Environmental certification – Establish environmental protection management systems through environmental management certification to carry out GX.

Resource recycling and reuse – Reduce resource waste by recycling (re-use waste materials, reduce product packaging, etc.)

Green supply chain – Promote manufacturing of green products by cooperating with green suppliers, stimulating GX of the entire supply chain.

Sustainable product design – Mitigate environmental impact through sustainable product design (use more eco-friendly materials, etc.)

To demonstrate these principles, exhibitors showcased five major trends:

- Tailoring comprehensive solutions to individual market demands

- Incorporating more green energy-saving technology applications into machine equipment and accessories using existing smart technologies

- Integrating smart energy management to implement more efficient green processes

- Implementing product lifecycle management (PLM) encompassing a comprehensive plan from product design to recycled packaging and carbon-reduced transportation

- Recognizing international energy-saving regulations and engaging in standardized product or qualification certifications

Exhibits

Key participating exhibitors in TMTS included Goodway, HIWIN, YCM, Takisawa, Victor, Tongtai Group (TTGroup), Quaser, TPI, Fair Friend Group (FFG), Buffalo, Siemens, Heidenhain, FANUC, and igus, among others.

YCM, celebrating its 70th anniversary, is the largest machine tool builder in Taiwan. It was recognized with the 2024 Taiwan Excellence Gold Award and the Machine Tool Industry Golden Energy Saving Label for its T11 Green Smart Machine. The T11’s entire design and manufacturing process incorporates low-pollution materials and energy-saving, carbon-reducing principles, according to YCM. Energy-efficient peripheral equipment minimizes power consumption, further reducing the T11’s carbon footprint – earning it ISO 14955 certification. The numbers show it can reduce seven tons of CO2 emissions and save 14,800kWh per year. The company’s digital twin solution provides a virtual, model-based simulation that can accurately estimate cycles time and simulate machining to prevent program interruptions and help plan costs.

Another Golden Energy Saving Label award went to HIWIN for its Mikrosystem line of linear motion drives and motors featuring vibration, torque, and temperature sensors. Featured in the booth was the Cartesian Robot-KK Series. Despite having one axis, the cantilever, cross, polar, and moving arm-type devices can be mounted on multiple surfaces to allow side-to-side or up/down motion in various automation applications.

TTGroup, Taiwan’s biggest machine tools group with seven brands and more than 120 machine models, was celebrating its 55th anniversary. Intelligent manufacturing capability was well represented with brand Tongtai earning two Golden Energy Saving Label awards (VP-12 vertical machining center, HTT500 horizontal machining center) and winning a silver award for the MT-1500 horizontal lathe. The T-BOT information system delivers feedback on machinery and software issues via generative AI, handling inquiries specific to Tongtai products ensuring data security and privacy. TTGroup’s Asia Pacific Elite Corp. (APEC) focuses on aerospace solutions with its G-800T featuring milling and turning with an 800mm rotary table.

Goodway’s GMT-2000 multi-tasking CNC lathe with 9-axis control and 5-axis simultaneous cutting won TMBA’s gold award for excellence in research and innovation.

Awea’s AU-680 high-speed 5-axis machining center demonstrated its suitability for turbine casing machining.

FFG showcased its Feeler VUX-400 4/5-axis vertical machining center in a work cell with automated loading and large-screen digital twin monitoring.

Campro Precision Machinery, known in North America via Campro USA, was well-represented with machines used in cutting helicopter and airplane parts. GM Zachary Tsai shared that AI is helping machine users to fix problems themselves. Capturing a QR code lets users identify a machine and error code and transmit it directly to the manufacturer without needing a telephone call.

Jainnher Machine Co. offers centerless, plunge/angular cylindrical, internal, center hole, double-spindle, and vertical grinding machines. The company has an international sales network with local dealers, VP Yi-Tung Chen says. The JHD-320S CNC twin-spindle machine for O.D. and I.D. grinding featured at TMTS has a new design and easy-to-use control.

You ji Machine Ind. Co.’s Overseas Sales Dept. Deputy Section Manager Jerry Wu says the company has had a quiet presence in aerospace for more than 20 years, selling more than 1,000 machines to more than 40 component and engine manufacturers globally. The MCR and HMC series machines make aircraft structure parts, the CTV and YB make landing gear and fasteners, while the VHL, VTL, and VTL+Y series are used in machining engine casings.

Ocean Technologies Co. specializes in drilling electrical discharge machining (EDM), offering its growing line of River series machines. President Sunny Liao explains how by replacing some metal castings with granite castings in the machine base, they’ve generated 50% energy savings in manufacturing while reducing carbon footprint by about 35%.

Accutex Technologies Co. also makes EDM machines, and its AZ-600A wire cut EDM won a Silver Taiwan Excellence award.

Palmary Machinery Co. will have its centerless, cylindrical, internal, vertical, and surface grinding machines at IMTS 2024. The Top-Work Industry brand offers high-precision CNC tool and cutter grinders (TA-5 and TG-5) for aerospace applications.

Concluding remarks

“The successful hosting of the TMTS exhibition not only showcases the advantages of the Taiwan machine tool industry in technological innovation and product development, but also highlights the achievements of Taiwan’s machine tool industry in cross-domain integrated ecosystem development,” Chen remarked. “We look forward to the continued achievements of the Taiwan machine tool industry in sustainable development, contributing more strength to the global machine tool industry’s development.”

Taiwan International Machine Tool Show (TMTS2024)

Taiwan Machine Tool & Accessory Builders’ Association (TMBA)

Explore the June 2024 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Bell awarded funding for X-plane build phase of SPRINT program

- Shaft coupling clamps

- #46 Lunch + Learn Podcast with SMW Autoblok

- Gleason Corp. acquires the Intra Group of Companies

- Thread milling cutter reduces cutting pressure, vibration

- Malaysia Aviation Group orders 20 more Airbus A330neo widebodies

- More displacement from space-tested piezo actuators

- Textron Aviation to bring its largest-ever lineup to 2025 EAA AirVenture