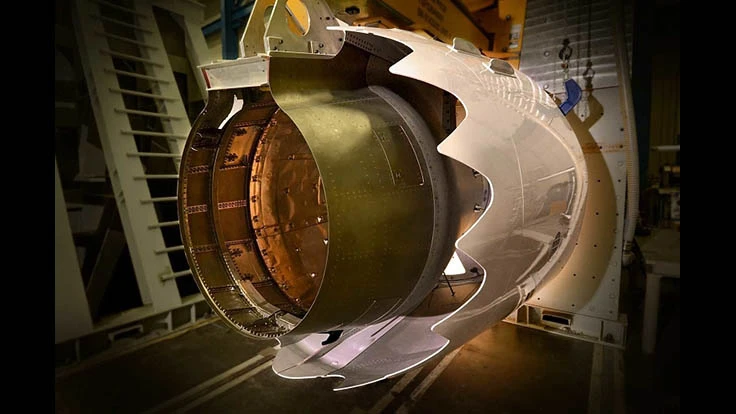

The first 737 MAX thrust reverser with a composite inner wall undergoing tests at Spirit AeroSystems' engineering lab.

Wichita, Kansas – Spirit AeroSystems Inc. has completed an expansion project on the Spirit Wichita campus to support production of the 737 thrust reverser. The expansion supports production rate increases already planned for the Boeing 737 program. The company also celebrated delivering the first 737 MAX thrust reverser with the new composite inner wall to the flight test program. Spirit produces the 737 MAX fuselage, pylon, thrust reverser and engine nacelle at its Wichita, Kansas, facility and the wing leading edges at its Tulsa, Oklahoma, facility. Spirit is responsible for delivering about 70% of the 737 structure to Boeing.

"We're excited to celebrate completion of this expansion project and delivery of the first thrust reverser with a composite inner wall," said Tom Gentile, Spirit AeroSystems president and chief executive officer. "Spirit has delivered assemblies and components for more than 9,000 737s since the model entered service, and we look forward to supporting the 737's continued success and competitiveness through this newest expansion."

Spirit is using a proven composite inner wall material, providing Boeing with a maintainable, producible and reliable solution for the 737 MAX. The new design includes a thermal protection system, which provides reliable protection from the heat generated by the new fuel efficient LEAP-1B engines made by CFM International. The 737 MAX is 20% more fuel efficient than the original Next-Generation 737.

The 737 MAX will extend the Next-Generation 737 range advantage with the capability to fly more than 3,500nm (6,510km), an increase of 340nm to 570nm (629km to 1,055km). Delivery of the first 737 MAX is scheduled for the first half of 2017.

Boeing, which currently produces 42 737s per month, will increase the rate to 47 airplanes per month in 2017. To support rate increases, Spirit also opened a new expansion to support 737 MAX thrust reverser production. The new expansion is 45,000ft2 and will deliver 94 thrust reversers per month to support the next rate increase.

"Delivering this very important capability to our customer is our top priority," said Duane Hawkins, Spirit's senior vice president of Boeing Programs. "Spirit helped design and develop a technical solution for our customer and now we have the capacity to deliver the product on time and with the highest quality possible."

Spirit employs about 15,000 people worldwide designing and building complex aerostructures for the world's most recognizable airplanes. Spirit builds the forward fuselage section of every Boeing Commercial Airplane in production today, as well as wing and propulsion components.

Source: Spirit AeroSystems Inc.

Latest from Aerospace Manufacturing and Design

- Ulbrich Stainless Steels & Special Metals acquires two ATI operations

- Abaco Systems' SBC3215 high-performance, rugged single-board computer

- IMTS 2024 Booth Tour: Hurco

- Soracle to bring AAM services to Japan with Archer eVTOLs

- Veterans Day

- Carter Manufacturing's bearings for ultra-high vacuum applications

- IMTS 2024 Booth Tour: Greenleaf Corporation

- Register now for November’s Manufacturing Lunch + Learn!