XSYTIN-360 end mills combine a phase-toughened ceramic XSYTIN-1 substrate with a cutting geometry offering 10x higher productivity compared to current solid carbide or ceramic products.

XSYTIN-1 ceramic material exhibits high wear and thermal shock resistance, making XSYTIN-360 end mills highly predictable, versatile, and high-performing. They’ve shown high material removal rates and increasing productivity on a range of materials, including high-temperature alloys, 3D-printed sintered high-temperature alloys, hardened steels, ductile cast irons, and compacted graphite iron (CGI). In hardened steels, the tool life of XSYTIN-360 end mills match high-performance carbide end mills when run at high speeds (11,460rpm), while also removing more than 73in3 (1,200cm3) of material.

Suitable for machining materials in the aerospace, automotive, die & mold, and power generation industries, XSYTIN-360 inch and metric end mills are available now.

Greenleaf Corp.

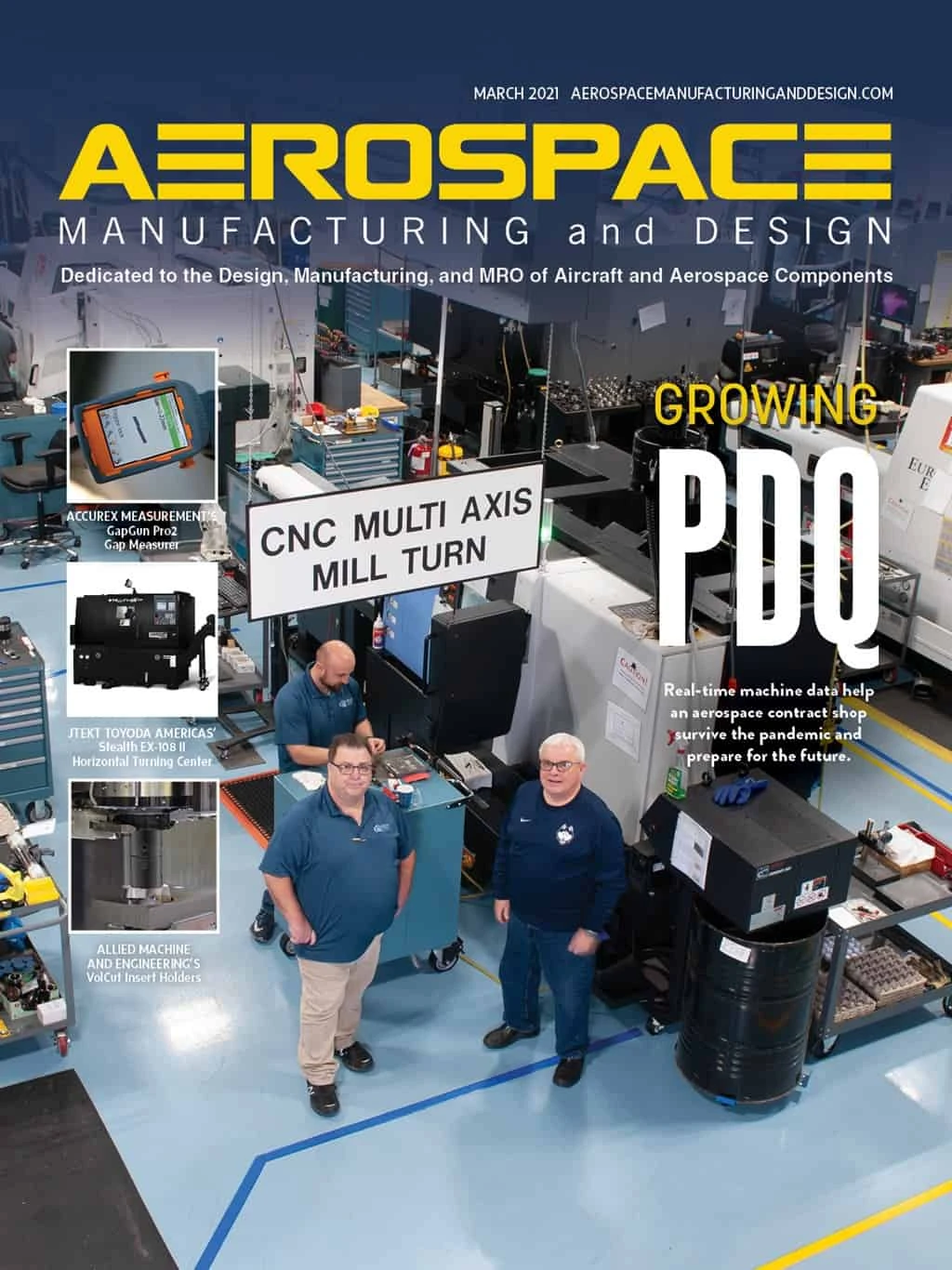

Explore the March 2021 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- AAMI project call submission deadline extended to May 12

- Jergens launches cast iron tooling column additions

- Airbus to acquire assets relating to its aircraft production from Spirit AeroSystems

- FANUC America's Cobot and Go web tool

- Chicago Innovation Days 2025: Shaping the future of manufacturing

- High-density DC/DC converters for mission-critical applications

- #59 - Manufacturing Matters: Additive manufacturing trends, innovations

- ACE at 150: A legacy of innovation and industry leadership