focused on numeric control (NC) programming, composite manufacturing, and 3D design.

Most CNC machine shops face the same problem: the programming office is backed up, so how can we keep machine tools running? Wooster, Ohio-based NobleTek CNC programmer Casey Carson and his colleagues use Vericut toolpath simulation and optimization software from CGTech Inc. in Irvine, California, to ensure smooth operations, preventing late deliveries, lost productivity, and unhappy customers.

Early discoveries

Carson has only been with the company a little more than a year, but he’s been using Vericut at various programming and engineering jobs for more than a decade. It wasn’t until he was several years into it, though, that a friend of his introduced him to some of the software’s more advanced features.

“Before that, I’d been using Vericut in the same way that many of our customers do – as a means to avoid crashes,” Carson says. “But, there are lots of little things such as advanced reporting, automation, graphing of the cutting forces, and so on that many people don’t realize are available in the base software. These are tools that any shop can use to make their programs run better and improve overall shop efficiency.”

Lending a hand

NobleTek uses a team approach, blending on-site and off-site professionals to meet customers’ project demands. In addition to CNC programming, NobleTek offers robotic programming, composite manufacturing, 3D-design, and data conversion. For Carson and his fellow programmers, a typical day involves taking customer CAD models and providing them with a proven, efficient, and crash-free set of NC toolpaths.

Carson mostly focuses on CATIA programming, while others in the department might use NX, Mastercam, GibbsCAM, or any of several other CAM packages. As a rule, they use whatever software their customer is using to maintain as seamless a handoff as possible. This includes Vericut.

“Most of our customers – the ones I work with anyway – are in the aerospace industry, and I’ve yet to see one that wasn’t using Vericut,” he says. “That’s a good thing, because accurate toolpath simulation is so essential to achieving what was intended when you’re programming the job.”

Cost-, crash-avoidance

Before working at NobleTek, Carson discussed the seemingly high cost of Vericut with former employers. His response was straightforward: “It’s a lot cheaper than a new spindle.”

Proving out a part the old-fashioned way – putting it on the machine and stepping through each line of code – is costly, but running Vericut eliminates that hassle and expense.

Even shops that don’t worry about spindle collisions because of skilled programmers can benefit from advanced Vericut features, Carson adds.

“How many cutters do people break? How many parts are scrapped? How many minutes or hours are lost proving out programs because they didn’t have Vericut?” he asks. “Then there are the things like automatic tool lists and setup sheets and all the different reporting capabilities – everything that you need to know about the job is in there, and all of these functions serve to make shops more efficient.”

Digging simulation

When asked how often Vericut has “saved his bacon” or that of his customer, he doesn’t have to stop and think about it. “Every day.”

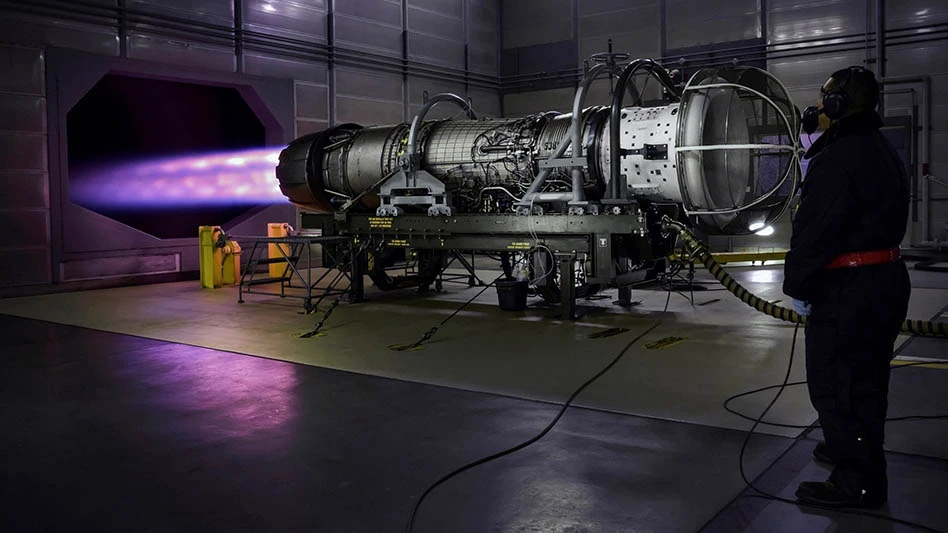

The ability to bulletproof programs for others is especially important in today’s manufacturing environment, where much of the industry’s tribal knowledge is retiring, and those few coming into the trades are often less skilled. At the same time, parts are becoming more complex, materials more difficult, machine tools faster and more expensive, and production quantities are generally falling.

Throw the increase in robotics and unattended machining into the mix, and it’s imperative that shops find the tools necessary to verify and optimize part programs long before the cutting tool first touches the metal.

“It’s such a small price to pay to find out if something works or doesn’t work,” he says. “Simulation lets me know if I’m tearing my machine up, and Vericut’s Auto- Diff function lets me know if my part’s good. And when I send the program to the customer, they’ll use Vericut to review how I ran the program and ensure that I’m cutting the part the way they wanted. It saves so much time, and so much money for everyone involved.”

Explore the June 2019 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- SW’s wing rib technology for the aerospace industry

- Mach Industries launches Mach Propulsion

- Murata Machinery USA's MT1065EX twin-spindle CNC turning center

- Electra reaches 2,200 pre-orders for its Ultra Short aircraft

- Heule's DL2 tooling for deburring of small bores

- Ralliant to establish global headquarters in North Carolina

- Philatron MIL-DTL-3432 military cables

- Beyond Aero refines its hydrogen-electric light jet