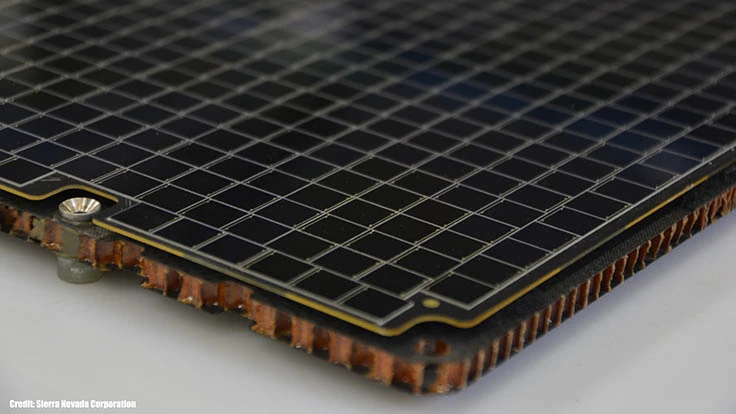

Sparks, Nevada – Sierra Nevada Corp. (SNC) and Solar Junction Corp. are launching a new technology to increase the efficiency of spacecraft solar array production and operation at lower cost. The advanced solar arrays are manufactured using a patent-pending surface mount technology (SMT) assembly method that allows each cell to be installed faster, closer together, and with more accuracy. This advancement increases the amount of power generated per area, while decreasing cost and delivery time. The San Jose, California-based Solar Junction’s high-efficiency, multi-junction Surface Mount Cell with Coverglass (SMCC) enables automated, high-speed, pick-and-place assembly of SNC-designed and manufactured solar arrays.

“In the last decade, we’ve noticed a critical industry need for smaller, lower-mass, higher-efficiency spacecraft systems,” said Matt Johnson, senior director of programs for SNC’s Space Systems business area. “Partnered with Solar Junction, our team is now able to meet these market demands. Our SMT arrays provide more power in a smaller package and at a lower cost.”

SMT allows SNC and Solar Junction to design, fabricate, inspect, and test a complete solar array in less time, benefitting overall spacecraft system design and performance.

In addition to the improved design, SNC has implemented a zero-touch labor process that reduces room for human error and allows each interface to undergo a more rapid and precise quality test. Once on-orbit, the small cell size and increased number of strings per panel makes the array more resilient to solar interference such as partial shadowing from the spacecraft and debris.

“Solar Junction’s patented cell technology enables us to simplify and automate the manufacturing processes for both the solar cell and solar array,” said Ali Torabi, director of corporate development at Solar Junction. “Our SMCC cells exceed 31% Air Mass Zero efficiency while maintaining industry-standard reliability requirements and radiation performance. We look forward to supporting SNC as it integrates this disruptive technology on an entirely new class of spacecraft.”

SNC recently completed its first contract to integrate this advanced technology onto its solar arrays under the Air Force Research Laboratory’s (AFRL) Satellite for High Accuracy Radar Calibration program. The 5U cubesat array will prove the efficiencies and benefits of this scalable system.

SNC has developed and delivered solar array systems for the ORBCOMM Generation 2 constellation, NASA’s CYGNSS spacecraft, and the AFRL’s STPSat-5, for which SNC is the prime contractor.

Source: Sierra Nevada Corp.

“In the last decade, we’ve noticed a critical industry need for smaller, lower-mass, higher-efficiency spacecraft systems,” said Matt Johnson, senior director of programs for SNC’s Space Systems business area. “Partnered with Solar Junction, our team is now able to meet these market demands. Our SMT arrays provide more power in a smaller package and at a lower cost.”

SMT allows SNC and Solar Junction to design, fabricate, inspect, and test a complete solar array in less time, benefitting overall spacecraft system design and performance.

In addition to the improved design, SNC has implemented a zero-touch labor process that reduces room for human error and allows each interface to undergo a more rapid and precise quality test. Once on-orbit, the small cell size and increased number of strings per panel makes the array more resilient to solar interference such as partial shadowing from the spacecraft and debris.

“Solar Junction’s patented cell technology enables us to simplify and automate the manufacturing processes for both the solar cell and solar array,” said Ali Torabi, director of corporate development at Solar Junction. “Our SMCC cells exceed 31% Air Mass Zero efficiency while maintaining industry-standard reliability requirements and radiation performance. We look forward to supporting SNC as it integrates this disruptive technology on an entirely new class of spacecraft.”

SNC recently completed its first contract to integrate this advanced technology onto its solar arrays under the Air Force Research Laboratory’s (AFRL) Satellite for High Accuracy Radar Calibration program. The 5U cubesat array will prove the efficiencies and benefits of this scalable system.

SNC has developed and delivered solar array systems for the ORBCOMM Generation 2 constellation, NASA’s CYGNSS spacecraft, and the AFRL’s STPSat-5, for which SNC is the prime contractor.

Source: Sierra Nevada Corp.

Latest from Aerospace Manufacturing and Design

- Molex to acquire AirBorn

- Nano Dimension's Exa 250vx digital light processing (DLP) 3D printer

- IMTS 2024 Booth Tour: Fagor Automation Corp.

- How Robotics and Automation are Transforming Manufacturing

- Wichita State’s NIAR delivers fiber metal laminate test panel to FAA

- Walter's PCD milling cutters

- IMTS 2024 Booth Tour: Marubeni Citizen-Cincom, Inc.

- Mazak celebrates 50th anniversary in Kentucky