Dayton, Ohio-based Reynolds Machinery, exclusive distributor for Hurco CNC machine sales and service in the Buckeye State, won the 2020 Top Unit Sales Award for North America.

Hurco representatives presented Reynolds Machinery with the award at the distributor’s showroom and technical center with the assistance of the Hurco Job Shop Automation Collaborative Robot.

National Sales Manager for Hurco Scott Camloh says, “Reynolds Machinery’s winning formula serves their customers well because they focus on support and service after the sale. They’re responsive to their customers and understand how to help them gain the greatest benefits from Hurco CNC machines.”

Watch a video of the Reynolds award being machined on a Hurco CNC machine.

Reynolds Machinery President, Scott Mays, hold the company’s Hurco 2020 Top Unit Sales Award for North America.

Airbus gears up for A321XLR assembly

Industrialization and parts production for the first A321XLR are underway by Airbus and its suppliers, paving the way for major component assembly of the first forward fuselage, center- and rear-fuselage sections, and wings, in the second half of 2021.

“The production of components for the first A321XLR flight-test aircraft is progressing through the sites all across the world, for large and small components as well as systems,” notes Gary O’Donnell, head of the A321XLR program. “In parallel, many parts are already being tested and demonstrated – on the aircraft structure and systems – to validate the functionality of those first aircraft components. The production system is now coming alive, with our teams receiving the design drawings from Airbus and the key risk-sharing design partners and bringing them into physical reality.”

Premium Aerotec Group in Germany is completing the final parts for the rear center tank and aft fuselage. Stelia Aerospace is producing parts for the aircraft’s nose and forward fuselage. Collins and Parker Aerospace are producing fuel & inerting systems.

Major sections of the A321XLR contain significant design changes from current A321neo/A321LR aircraft, especially the center and aft fuselage integral rear center fuel tank and fuel management systems – key to the aircraft’s 4,700nm range – 15% more than the A321LR version.

Wind River, Curtiss-Wright collaborate on cybersecurity

Software company Wind River Systems is collaborating with Curtiss-Wright Defense Solutions to offer integrated cybersecurity and anti-tamper protections for aerospace and defense systems, enabling their customers to meet security and performance requirements for mission-critical applications.

Wind River’s Titanium Security Suite has been integrated, tested, and validated on Curtiss-Wright OpenVPX modules. The collaboration enables customers to integrate security during the design phase, incorporating advanced cybersecurity and technology protections that meet Defense Department requirements.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

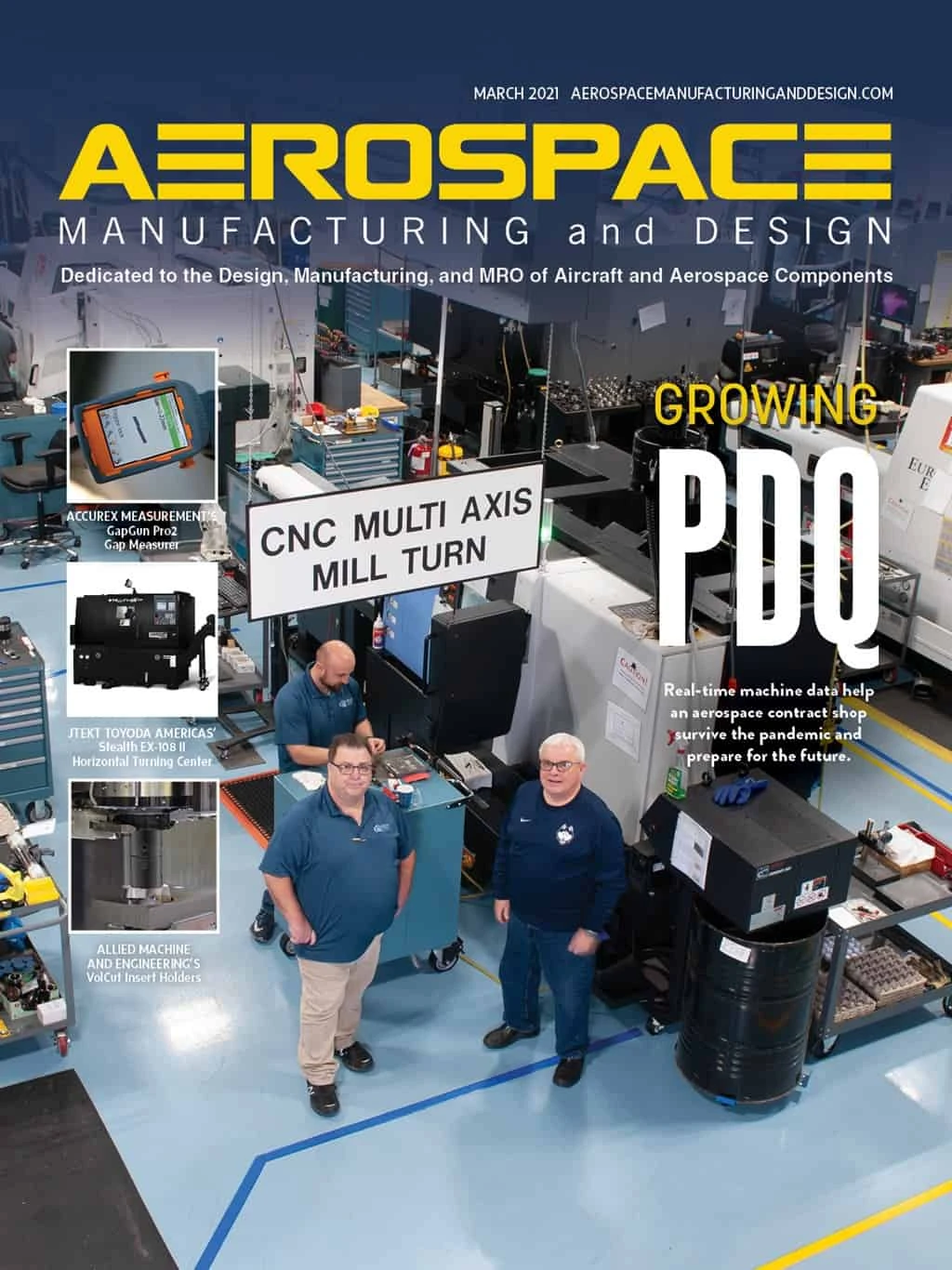

Explore the March 2021 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Piasecki acquires Kaman's KARGO UAV program

- PI Americas’ long-travel XY piezo nanopositioners-scanners

- AAMI project call submission deadline extended to May 12

- Jergens launches cast iron tooling column additions

- Airbus to acquire assets relating to its aircraft production from Spirit AeroSystems

- FANUC America's Cobot and Go web tool

- Chicago Innovation Days 2025: Shaping the future of manufacturing

- High-density DC/DC converters for mission-critical applications