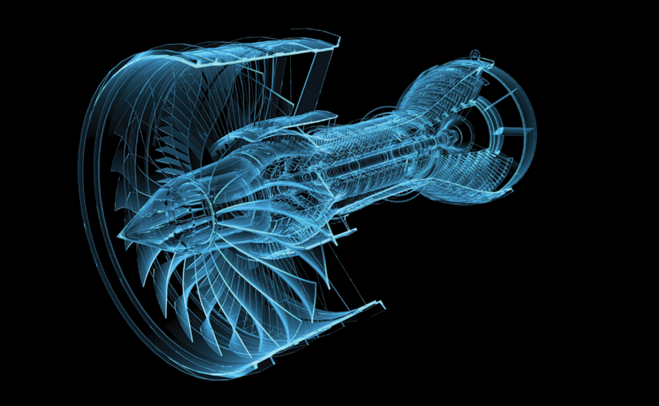

High fuel prices, stricter emissions regulations, and intense competition from low-cost carriers are driving a quest for more efficient aero-engines and components, and even small advantages can drive major benefits.

Turbine blades are no exception, according to a recent report by Market Research Future suggesting that the market for commercial aircraft turbine blades is set to grow at a compound annual growth rate (CAGR) of 6% by 2023.

The casting industry is investing to meet this demand and looking to gain advantages in every aspect of manufacture, including for the support rods used in the production of turbine engine blades. The two most commonly used materials to cast these are quartz (silica) and alumina.

Quartz, the traditional material of choice, is chemically weak and fast to leach, which accelerates and simplifies production. On the other hand, its mechanical weakness can lead to processing issues and defects during investment casting of difficult metals such as super-alloys.

Alumina rods have about 4x the mechanical strength of quartz and have high strength and load-bearing capabilities. However, alumina is so chemically strong it can take several days to fully leach out the material, resulting in longer production times.

While the two materials offer almost opposite properties, they share one common advantage: neither create trace elements that can contaminate processes or compromise part quality and performance.

Neither material is perfect, but what if there was a way to combine the best properties of each?

Making LEMA

This was the challenge Morgan Advanced Materials set itself in 2015, resulting in LEMA proprietary alumina-based materials that provide 2x the mechanical strength of quartz without the leaching times of typical high-purity alumina.

Following significant experimentation, the solution lay in combining two materials in the right balance – a complex task, especially as the materials in question were so different.

Morgan’s laboratories started with a method borrowed from glass science – using two distinct phase-separate materials to improve mechanical properties such as toughness or to provide a leaching path through the chemically weaker glass. Ultimately, the laboratories created an alumina-silicate ceramic with a leaching path of silica across the grain boundaries. Adjusting particle size distribution and processing parameters produced the desired mechanical strength. LEMA entered the market in 2017.

Fast leaching, no strength loss

LEMA is almost 2x as strong as quartz and has a slightly lower thermal expansion coefficient than alumina, which can help with metal leakages sometimes encountered with alumina rods during casting. Made of pure materials, LEMA satisfies the requirement for trace-element certification.

LEMA crumbles out when flushed, making it easier to remove during leaching. Moreover, LEMA 250 parts will experience approximately a 20% mass reduction after 20 hours at 300°F (149°C) and 185psi. Under the same conditions, a comparable alumina part does not demonstrate any mass loss.

In addition to its advantageous chemical and mechanical properties, LEMA can reduce investment casting times in turbine engine blades by accelerating leaching by up to 20%, solving many delays and production challenges.

Less need for autoclave time during the leaching process spares manufacturers some of the costly investment in additional equipment.

LEMA offers a powerful solution for the investment casting of turbine blades, just as the industry is facing an increased demand for these critical components. Combining the best aspects of quartz and alumina represents the best of both worlds as well as a major breakthrough for the industry.

Morgan Advanced Materials

http://morganadvancedmaterials.com

About the author: Eric Larson is director of technology and process improvement for Morgan Advanced Materials’ Technical Ceramics business. He can be reached at 510.491.1100 or marketing@morganplc.com.Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Explore the March 2019 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Ralliant to establish global headquarters in North Carolina

- Philatron MIL-DTL-3432 military cables

- Beyond Aero refines its hydrogen-electric light jet

- Americase's advanced protective solutions

- Social media - what are your thoughts

- GE Aerospace secures Air Force engine contract

- Thomson Industries' online sizing and selection tool

- #53 - Manufacturing Matters - 2024 Leaders in Manufacturing Roundtable