Small crystal oscillators

The QTC series of ultra-miniature XO, TCXO, and VCXO devices feature high stability and a wide operating temperature range. The oscillators boast stability as tight as 50ppm from -55°C to 125°C as well as 0.5ppm from -40°C to 85°C. All devices in the QTC line are available with full MIL-PRF-55310 level B screening and offer low phase noise and jitter.

Based on product type, available dimension types are 2.5mm x 3.2mm, 3.2mm x 5mm, and 5mm x 7mm.

Q-Tech Corp.

https://q-tech.com

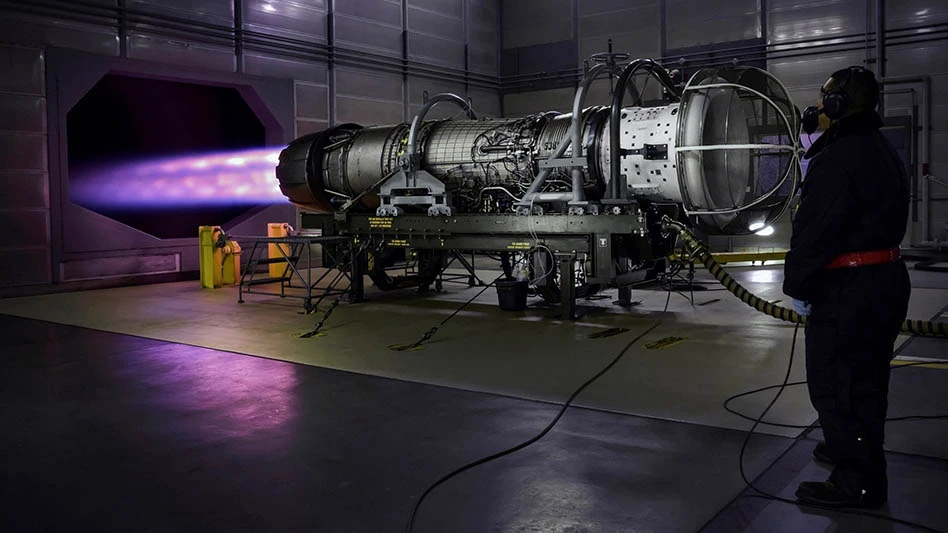

Controlled atmosphere DED systems

LENS CS 600 and CS 800 controlled atmosphere (CA) systems use an additive manufacturing technique called directed energy deposition (DED), where high-powered lasers build structures by layers directly from powdered metals, alloys, ceramics, or composites to produce fully-dense parts with mechanical and fatigue properties.

The systems are configurable and maximize the process build envelope with a minimal system footprint. Both come standard with controlled atmosphere chambers, processing non-reactive and reactive metals in an atmosphere that maintains less than 10ppm oxygen levels. The systems are also compatible with the LENS deposition head, providing higher power laser processing up to 3kW, interchangeable print nozzles, and variable spot sizes.

LENS machines are equipped with a linear 3-axis motion system, but optionally can be delivered with a user interchangeable rotary table and/or tilt-rotate trunnion for 4- and 5-axis operations.

Optomec

http://optomec.com

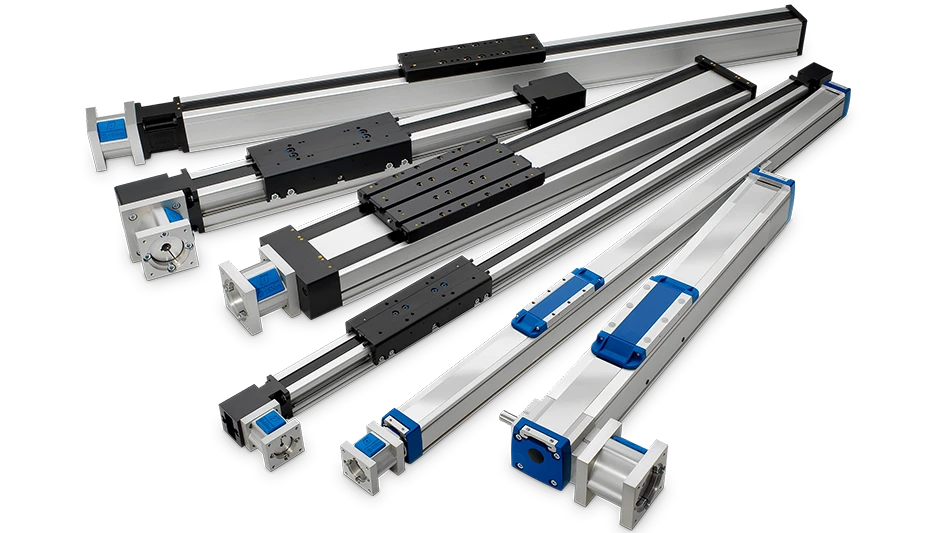

5-axis multi-sensor CMM

Altera CMM’s SCANtek 5 is coupled with Renishaw’s REVO-2 scanning system and multi-sensor technology, offering a 5-axis solution for inspecting dimensional accuracy and surface finish.

The multi-sensor package includes Renishaw’s MODUS software for importing data, controlling the CMM and acquiring results and reports.

SCANtek 5 is available with measuring volumes from 800mm x 700mm x 600mm to 6,000mm x 2,000mm x 1,000mm, with larger options. The CMM scans without the stylus leaving the component surface, allowing coordinates of up to 4,000 points to be captured on-the-fly every second. Infinite head positioning flexibility increases the effective measuring volume by minimizing the need for head reorientations, while performing highly complex measurements. Exchanging the REVO-2 scanning probe for one of the vision probes can increase data collection rates, and results can be correlated with those acquired using tactile methods.

By employing different tip arrangements and knuckle joints, detailed surface finish analyses can be combined with other CMM measurements in a single operation, the basic output being Ra, RMS, and raw data.

LK Metrology

https://www.lkmetrology.com

EASTEC 2019 Booth #3310

Explore the April 2019 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Drop in for an interactive webinar on automation in manufacturing

- SW’s wing rib technology for the aerospace industry

- Mach Industries launches Mach Propulsion

- Murata Machinery USA's MT1065EX twin-spindle CNC turning center

- Electra reaches 2,200 pre-orders for its Ultra Short aircraft

- Heule's DL2 tooling for deburring of small bores

- Ralliant to establish global headquarters in North Carolina

- Philatron MIL-DTL-3432 military cables