Oerlikon

Oerlikon Metco Coating Services (MCS)’s new laser cladding service center is fully operational in Huntersville, North Carolina, a Charlotte suburb.

As previously communicated, Oerlikon planned to expand their existing world-class additive manufacturing facility to include laser cladding and thermal spray services; thereby implementing a service super center under one roof and allowing the company to conveniently offer Print & Coat parts.

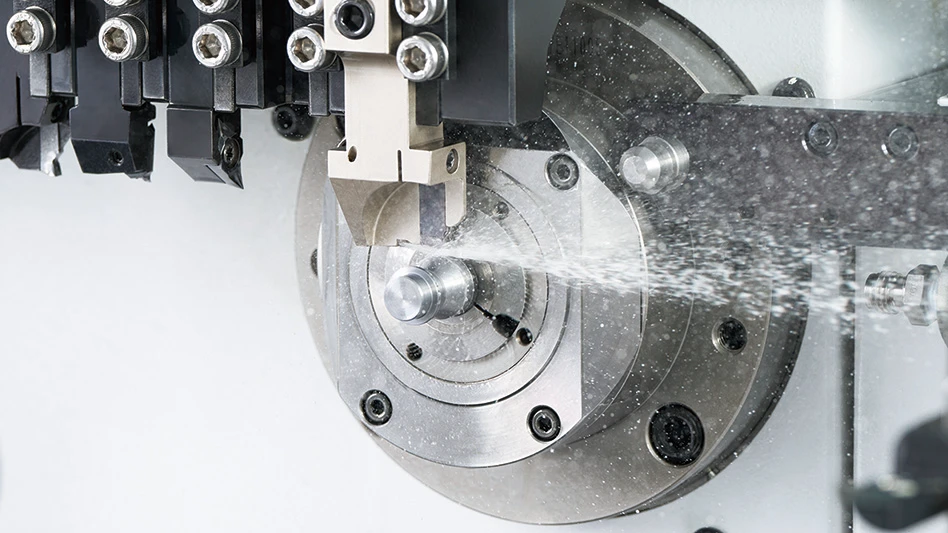

Laser cladding services are now fully operational at this facility with the ability to offer O.D. and I.D. coatings, as well as laser hardening, pre- and post-machining, and inspection services.

The facility is equipped to handle a wide range of parts, with a maximum part weight of 15,000 lb (6,800kg), maximum part length of 480" (12,192mm). Outside diameters up to 96" (2,438mm), as well as inside diameters from 2" to 120" (50.8mm to 3,048mm) can be processed.

Experienced personnel at the Huntersville location and the company’s long history of laser cladding solution development will serve the aerospace, energy, and automotive markets, among others.

“Laser cladding is increasingly an important process in the services that Oerlikon, through Oerlikon Metco Coating Services, can offer. We are therefore excited to see this new facility now in operation and already serving our customers,” states Thomas Meier, global head of sales for MCS. The substantial investment at the Huntersville facility, along with a recent significant investment in new, leading edge laser cladding equipment at the company’s Wohlen, Switzerland facility, punctuates the importance of laser cladding to the overall coating service strategy. In addition, the company continues to develop new materials optimized for the laser cladding process.

In addition to the laser cladding expansion at Huntersville, thermal spray coating equipment is currently being installed and planned to be operational at the same location at the end of Q1 2022.

Oerlikon Metco enhances surfaces through a broad range of surface technologies, equipment, materials, services, specialized machining services and components. Surface technologies such as thermal spray, laser cladding, and laser hardening improve performance and increase efficiency and reliability.

Oerlikon AM provides additive and conventional manufacturing solutions with metals and polymers. The extensive portfolio of solutions offered ranges from the co-development and contract manufacturing of high-quality and performance-optimized components, through research and development, to the production of the company’s own metal powders for 3D printing. Materials, process and applications engineering, certified manufacturing processes, post-processing of components and quality management enable Oerlikon AM to provide optimally customized comprehensive solutions. Together with Oerlikon Balzers and Oerlikon Metco, Oerlikon AM forms the Surface Solutions segment of the Swiss-based Oerlikon Group. Oerlikon AM employs more than 200 people at four sites throughout Europe, the United States, and China.

Latest from Aerospace Manufacturing and Design

- November Lunch + Learn with Fagor Automation

- Able Aerospace SMS earns FAA acceptance

- Iscar's CERMILL endmills with ceramic round inserts

- IMTS 2024 Booth Tour: Okuma America Corp.

- Solar Atmospheres of Western PA gets Pratt & Whitney approval

- Tungaloy’s TungBoreMini drilling and turning tool

- 3 Questions with an Expert: Mitutoyo

- Optimize your manufacturing applications with the right metrology tools