The FBX drill for flat-bottom drilling offers up to 200% higher metal removal rates compared to traditional ramping techniques when machining high-temperature alloys, stainless steel, other steels, and cast irons. The drill is part of a three-step tooling concept that maximizes metal removal rates and decreases cycle times when machining aerospace structural components.

Combining the advantages of a flat bottom drill and a Z-axis plunge mill, the FBX drill speeds up machining compared to the traditional time-consuming, low metal removal rate first process step of entering the material using ramping techniques. The flat bottom design eliminates radial forces while four cutting edges provide increased feed and speed rates. Once the drill has shaped the basic structure of the component, the next process steps are roughing and finishing with indexable and solid end mills.

Four cutting edges provide stability in challenging applications such as chain hole drilling and plunging, while large chip flutes ensure hassle-free chip evacuation. Supported by a series of exchangeable coolant nozzles to help eliminate heat buildup, the drill point has a center insert with two cutting edges and chip splitters for maximum feed capabilities.

Drill bodies are available in 60mm, 75mm, and 90mm diameters, in 150mm and 95mm lengths. The modular drill connects to bolt taper flange (BTF) mount adapters, available in various spindle connection styles.

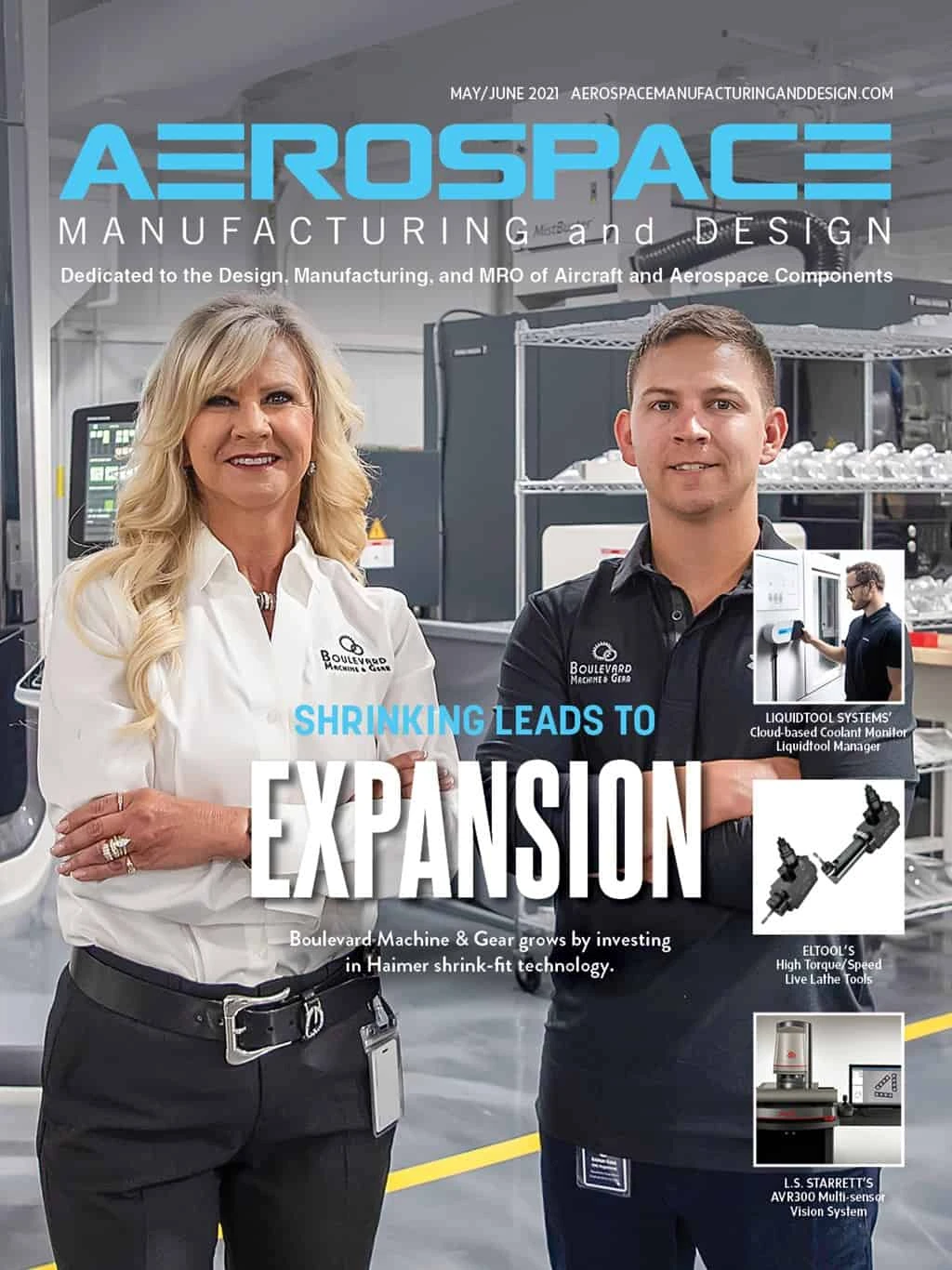

Explore the May June 2021 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Revitalizing the Defense Maritime Industrial Base with Blue Forge Alliance

- Safran Defense & Space opens US defense HQ

- Two miniature absolute encoders join US Digital’s lineup

- Lockheed Martin completes Orion for Artemis II

- Cylinder CMMs for complex symmetrical workpieces

- University of Oklahoma research fuels UAS development

- Motorized vision measuring system

- Everyone's talking tariffs