Marposs is a leading global supplier of precision metrology equipment for shop-floor inspection, measurement, and process control solutions, which help to improve quality and reduce costs in manufacturing.

Marposs can supply products ranging from an individual gaging component to turnkey machines or fully automated lines to address customer needs worldwide, supplying the metrology equipment associated with non-destructive testing, leak testing, and a wide variety of sensors and machine tool controls.

The company makes equipment capable of measuring to the thousandth of a millimeter and more. Plus, these tasks can be performed in a workshop environment along the production line, and on any machine tool instead of in a metrology lab.

Marposs serves a wide variety of industries including machine tool, automotive, aerospace, medical, and others, where the company has a hand in supplying gaging and testing equipment for many types of applications.

Aerospace

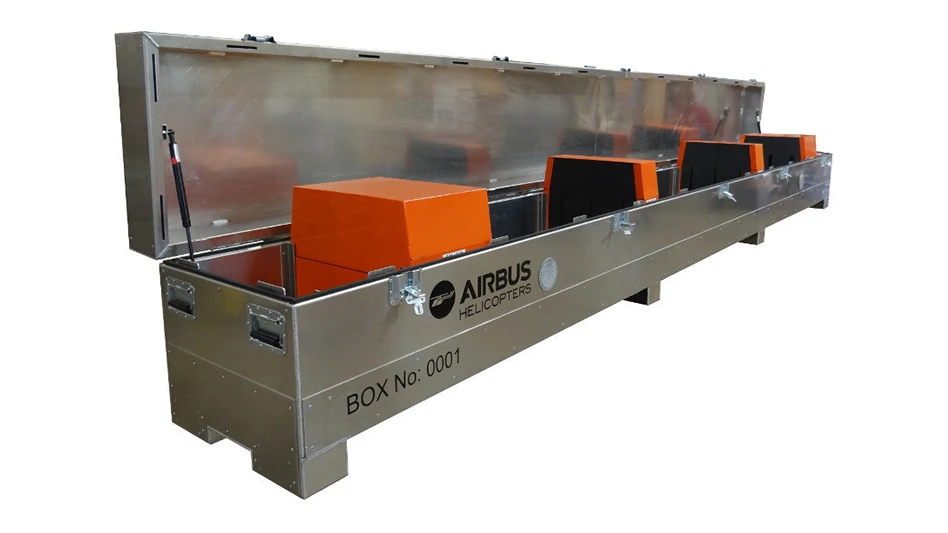

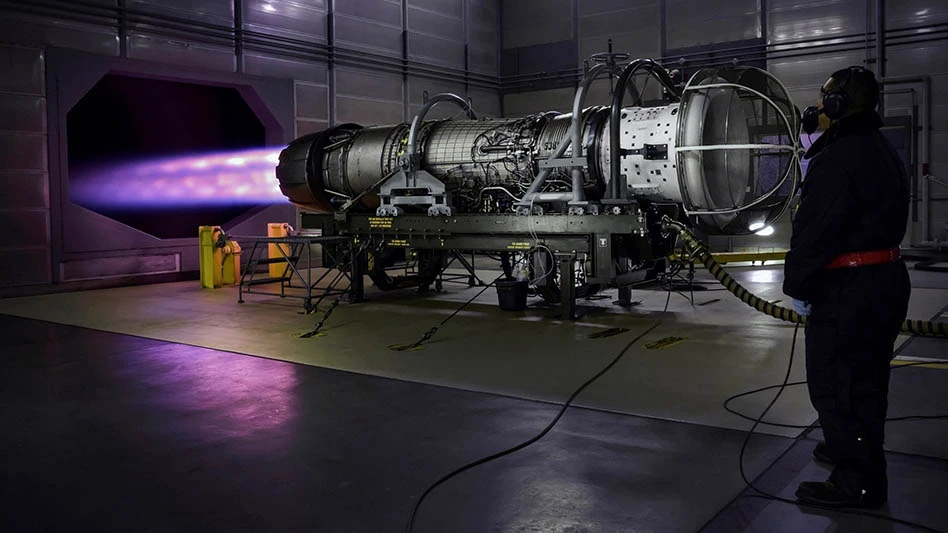

Marposs has many years of experience in the design and manufacture of tooling, fixtures, machine monitoring systems, and automatic inspection machines that perform checks on specific parts used in aeronautics and space sectors. Marposs systems are used for assembly, final inspection, and MRO of almost every modern aircraft engine manufactured. Throughout the last few decades, we have supplied thousands of gaging/tools systems to customers worldwide; the most of any gage manufacturer in the world.

Automotive

For the automotive and transportation industries, Marposs provides a full depth of gaging and measurement solutions for components that are used in engines (combustion and battery-powered), transmissions, car body and chassis, automotive glass, lighting, and more.

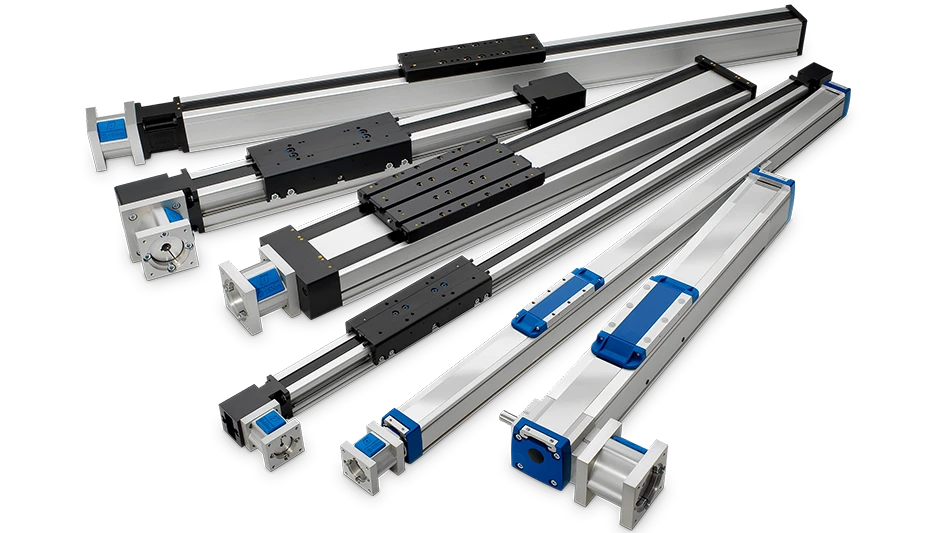

Solutions can vary from standardized components to tailor-made systems built to fulfill customer specifications. Standard solutions encompass in-process and post-process applications for machine tools, hand-held gages to check diameters and simple geometries, or gaging components to build gaging stations.

Our dedicated solutions include benches and machines for manual, semiautomatic, or fully automatic inspection of multiple parameters; equipment for non-destructive testing based on eddy current technology; and equipment for leak testing, such as battery components.

Medical

Within this industry, it is typical to require inspection of 100% of component production. Marposs has solutions for measuring tubes, orthopedic joints, medical sets, and more, as well as equipment used for dialysis or assisted breathing.

We offer several types of leak testing technologies for applications such as bags for liquids (blood, feeding, pharma solutions) and bottles. In addition to typical leak or flow tests, volume and resistance (burst tests) are checked with functional and destructive tests. Sealed products such as single dose, are commonly tested by interception, in bell or in vacuum.

In all we do, Marposs adheres to quality principles and is committed to the continuous improvement of procedures and methods, as well as the adoption of new methods most suitable for the analysis, engineering, production, control, and assistance of all our products and services.

Marposs’ expertise enables our customers to reach their goals of product quality, efficiency, flexibility, productivity, reliability, and maintainability of the manufacturing process, regardless of their company size.

FOR MORE INFORMATION:

https://www.marposs.com

Explore the Inspection Target Guide Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Drop in for an interactive webinar on automation in manufacturing

- SW’s wing rib technology for the aerospace industry

- Mach Industries launches Mach Propulsion

- Murata Machinery USA's MT1065EX twin-spindle CNC turning center

- Electra reaches 2,200 pre-orders for its Ultra Short aircraft

- Heule's DL2 tooling for deburring of small bores

- Ralliant to establish global headquarters in North Carolina

- Philatron MIL-DTL-3432 military cables