A question I’ve been asked many times through the years is, “Do you need to have balanced tooling?” Many tool makers advertise balance by design, but does that mean the tooling is balanced? The tool may be balanced by design, but the minute you put a tool in the holder it’s no longer balanced and you have to decide if you’re going to use the tool as it’s assembled or if you must balance the total assembly.

When you look at any toolholder without a tool in it, determine if it looks like it could be a balanced tool. Let’s take an end mill holder for instance. You’ll find that on one side it has two tapped holes where set screws are used to hold an endmill in place. Knowing that you have two drilled and tapped holes on one side and none on the other means this can’t be a balanced tool. Look at the end mill you will use. In many cases it has two flats milled on one side so the set screws can be tightened against them to hold the tool. Looking at this you know the end mill isn’t balanced, therefore the tool assembly isn’t balanced either.

You will find similar instances in all the tooling on your machine. When a tool is out of balance it puts stress on spindle bearings. Throughout time, continued pressure will cause spindle problems and ultimately require premature spindle replacement. Another concern is that unbalanced tooling causes your tooling to reach end of life earlier due to uneven cutting forces. Also, surface finishes are harder to obtain when tooling is out of balance.

Higher spindle rpm and faster running machines require balanced tooling to protect you and your equipment. Safety being the most important issue here in protecting your most valuable assets – your employees. There are many other benefits as we have already discussed: better quality of parts, longer tool life, and longer machine life.

I suggest that you balance all your rotating tooling prior to use. Work with your local providers for balancing tooling assemblies. I’m sure you’ll see the benefits and your returns will far outweigh the cost.

CMR Consultants

miker2468@aol.com

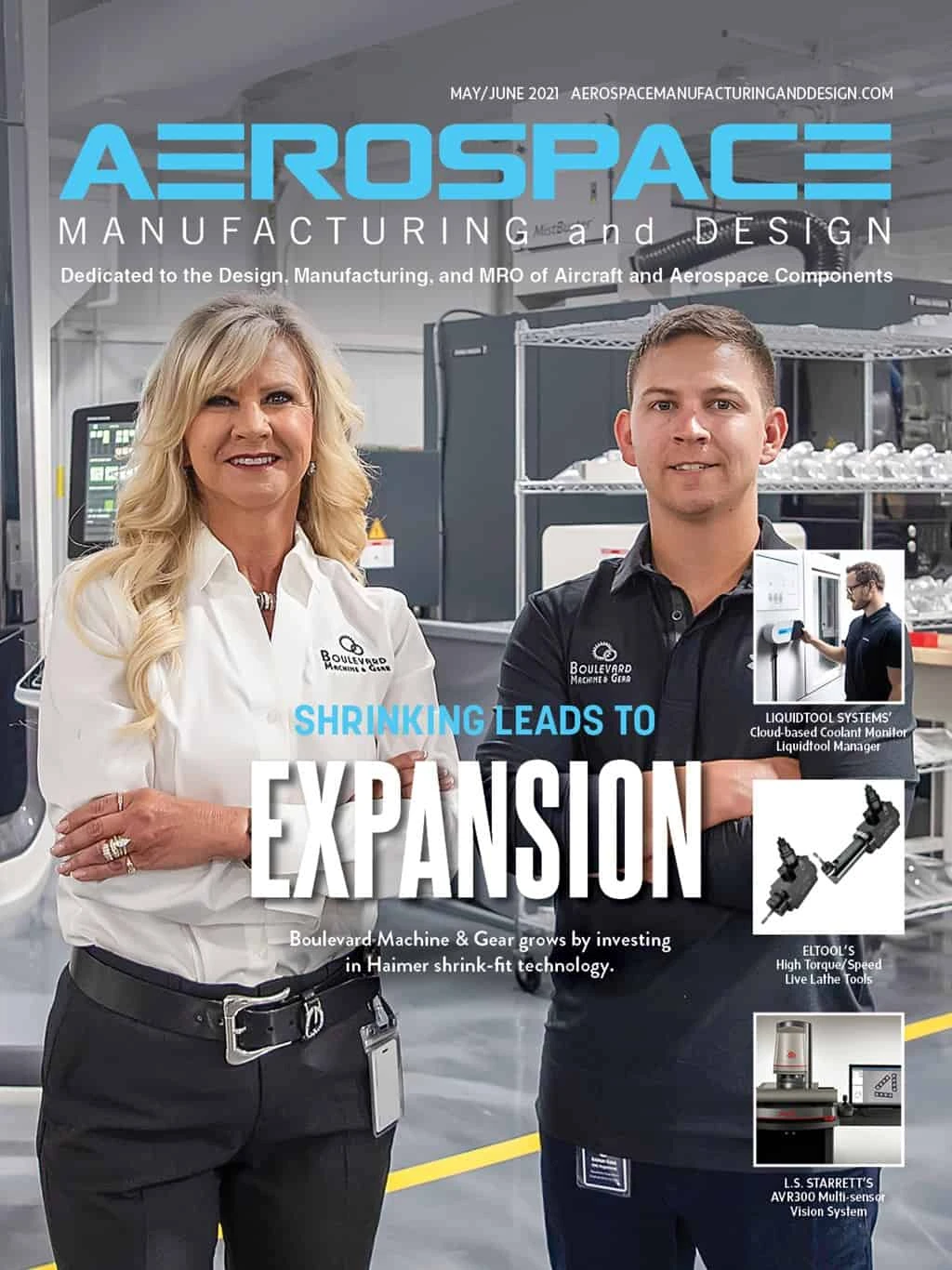

Explore the May June 2021 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- The 5 Best and Fastest Spindle Repair Services

- Mill smarter, not harder: How collaboration optimizes production

- Be proactive – stay ahead of tariffs and other economic and supply chain curveballs!

- Taiwan’s China Airlines orders Boeing 777X passenger, freighter jets

- Reamer re-tipping extends life of legacy tooling

- Revitalizing the Defense Maritime Industrial Base with Blue Forge Alliance

- Safran Defense & Space opens US defense HQ

- Two miniature absolute encoders join US Digital’s lineup