Collaborative robots (cobots) assist human workers and can handle extraordinary circumstances, even a novel global pandemic. As the technology changes and expands capabilities, cobots have become increasingly important due to growing demand for enhanced productivity, speed, and safety. According to the latest report by Research and Markets, the cobot market is projected to grow at a compound annual growth rate (CAGR) of 30.37% from 2020 to 2025. Kristian Hulgard, general manager – The Americas at OnRobot, examines factors influencing this growth and poses expectations for what’s ahead.

Aerospace Manufacturing and Design (AM&D): What value is created with collaborative operations, and what are the advantages of having these systems in place?

Kristian Hulgard (KH): For us, it’s about creating value in the entire supply chain. It’s not only about creating value for the end user, but also for the integrators and distributors. Automation is easy to use for quick and effective deployment with shorter integration time and lower costs. In addition, because it’s flexible, the manufacturer can manage, operate, and maintain a program on their own.

Collaborative operation is also addressing current challenges in the market. It solves labor shortages, improves product quality, increases productivity, provides fast return on investment (ROI), and helps with social distancing to keep workers safe. It was very popular in the 1990s to outsource manufacturing to Asia; now collaborative operations help with the changing focus toward reshoring.

AM&D: The market is heavily focused on software-driven solutions. Where are you seeing this shift and why?

KH: Traditionally, components on a robot and integrated in an application cell were pneumatically driven, so it was either on or off. Those were the only two options. Now demand from the market is leaning more toward electric tools and accessories controlled by software. Instead of end of arm tooling (EOAT) having only one function, they are more flexible and have multiple capabilities. For example, a gripper doesn’t only get one part, the gripper can grip different shapes, sizes, and materials. And with more Industry 4.0 capabilities in place, manufacturers can monitor their manufacturing in the cloud, determine maintenance ahead of time, and monitor machines to see how the robot is running and its effectiveness. If you have software driven tools, sensors, and cameras, then you can export that and optimize your production, meaning you’re more productive and profitable.

AM&D: What is the market outlook for cobots, and what trends are you seeing?

KH: Like the rest of the world, we were of course challenged by COVID-19. As many manufacturers made shifts in production and found new use cases for cobots, newcomers to automation demonstrated more growth compared to the more traditional cobot and light industrial robot industries. Looking into 2021, I believe we’ll see more traditional automation users come forward again.

AM&D: How will application design change and advance?

KH: There are many more companies taking the software and the plug-and-play approach, and I think that’s the future. You integrate a part onto the robot, connect it to the controller, and you’re ready to use it instantly. I can also see the difference as more manufacturers are partnering to develop these application capabilities. I would say in 5 to 10 years, for lightweight, industrial and collaborative robot application design, it’ll be something you can do online, through drag and drop, put all your components in something that will generate what you need, and then send it to your local distributor who will ship you the parts.

I also think that data and machine learning will involve simpler, almost fully automatic application programming. Light industrial robots will be standard components in the collaborative operation. The focus will shift more to how easily and quickly the solution can solve a problem.

AM&D: Why is developing one language for all robots so important for the future?

KH: We want one language and one software for all robots so we can open automation to everyone. It’s very important to look at components and parts for the application, where you have just one control or one language. Compatibility is usually a huge barrier, especially for small- and medium-sized enterprises (SMEs) when they don’t have a complete overview of all the components and each part has its own language. It’s critical to have one single common platform so that we can give users the safety and confidence they need to use any tool.

AM&D: What do you anticipate moving forward in this market?

KH: I think there’ll be less talk about specific gripper or robot functions, and we’ll be focusing more on solutions, but how are we going to get there as fast as possible? With easily deployable robots.

The International Federation of Robotics states that we’re going to sell 10x as many robots in five years. And my question to the industry is, how are you going to contribute to 10x as many robots deployed? The answer is not going to be hiring 10x as many engineers or salespeople. It’s determining how to deploy a robot or automation solution faster and more effectively. In the time that I spend deploying one robot today, in five years, I can deploy 10 robots. That’s key to the market’s success, and there are several companies contributing to that. Eliminating deployment time and decreasing hours on design, installation, and programming is essential.

About the author: Michelle Jacobson is the assistant editor of AM&D. She can be reached at mjacobson@gie.net or 216.393.0323Get curated news on YOUR industry.

Enter your email to receive our newsletters.

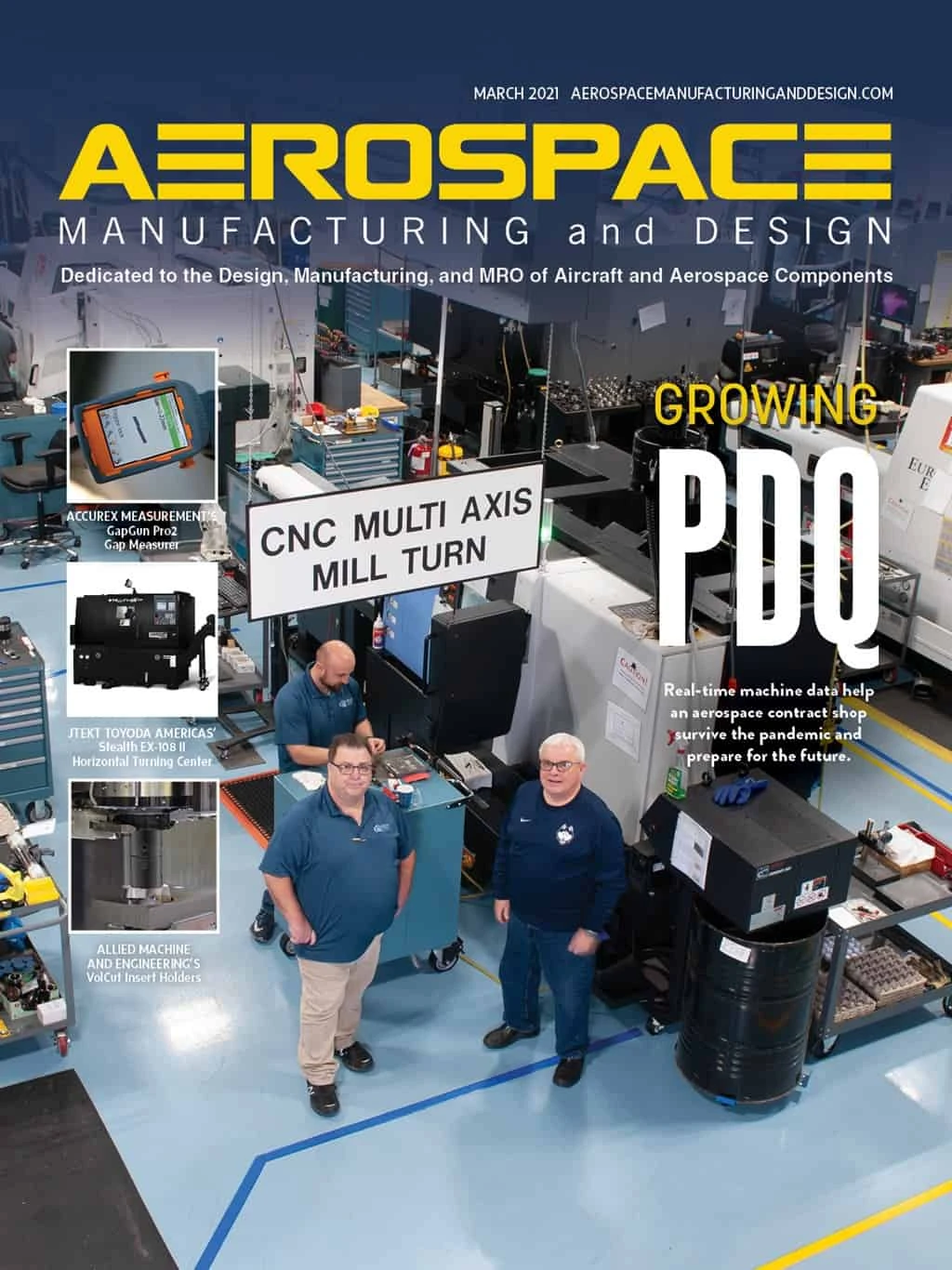

Explore the March 2021 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- NASA offers free high school engineering program this summer

- Pemamak's PEMA Vision 3D software

- Aerospace Industry Outlook - Spring 2025, presented by Richard Aboulafia

- Panama’s National Air and Naval Service selects Embraer Super Tucano

- Model 5770 Linear Abraser

- #42 Lunch + Learn Podcast - Quell Corp

- RECARO Aircraft Seating showcases advanced comfort solutions at AIX 2025

- Mitutoyo America’s MiSTAR 575 Shop Floor CNC CMM