Structur3D Printing has launched the Inj3ctor platform, combining principles of injection molding with 3D printing for aerospace manufacturing.

Using 3D printing technology combined with rubber/silicone injection molding, Structur3D allows small-batch manufacturing of high-quality, custom products without increased costs.

By injecting a 3D-printed mold with professional-quality materials, manufacturers can create custom products that are viable from prototyping to production.

The Inj3ctor platform creates 3D-printed products with factory-grade rubber materials, such as silicones and polyurethanes.

Metal 3D printing calculator

The Production Metal Cost Calculator estimates per-part costs for binder jet 3D printing a precision metal part, allowing quick comparisons to other forms of traditional and additive manufacturing.

The tool requires just a few easy inputs – material, machine, part dimensions, and volume – and is based on the purchase of any one of ExOne’s four Pro series printers.

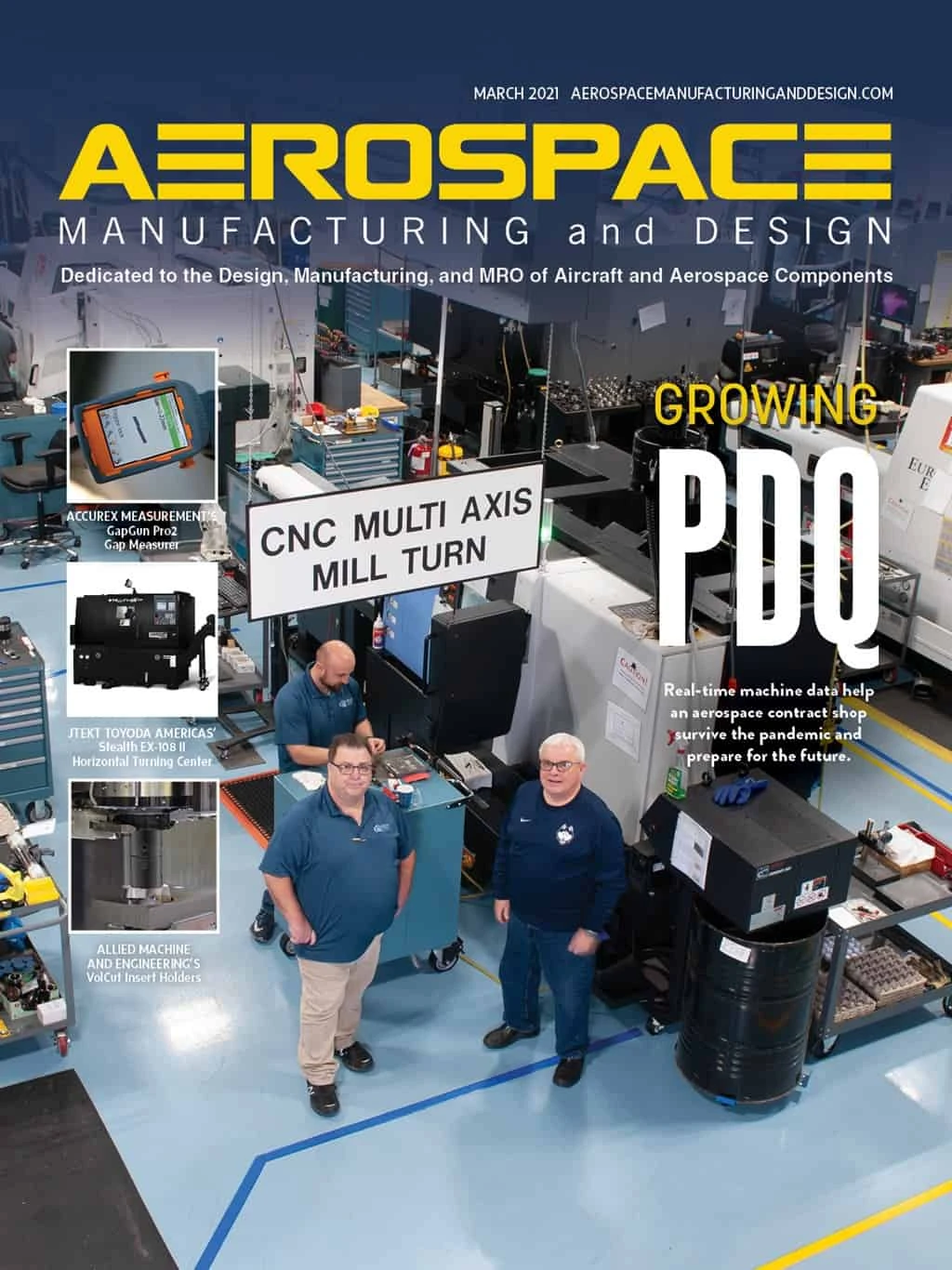

Explore the March 2021 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- AAMI project call submission deadline extended to May 12

- Jergens launches cast iron tooling column additions

- Airbus to acquire assets relating to its aircraft production from Spirit AeroSystems

- FANUC America's Cobot and Go web tool

- Chicago Innovation Days 2025: Shaping the future of manufacturing

- High-density DC/DC converters for mission-critical applications

- #59 - Manufacturing Matters: Additive manufacturing trends, innovations

- ACE at 150: A legacy of innovation and industry leadership