A horizontal profiler, the new HyperMach H4000, features 5-axis contouring, 2m x 4m (6.5ft x 13ft) pallet capacity, full-portal open-center construction, and industry-best horizontal machining productivity. Cutting operations are totally enclosed with chip through to a high-volume conveyor, avoiding chip re-cutting and the need for a chip blow-off attendant. Cell-ready, the H4000 can be easily integrated/expanded for multiple machine processing using MAG Cincinnati CINCRON cell modules.

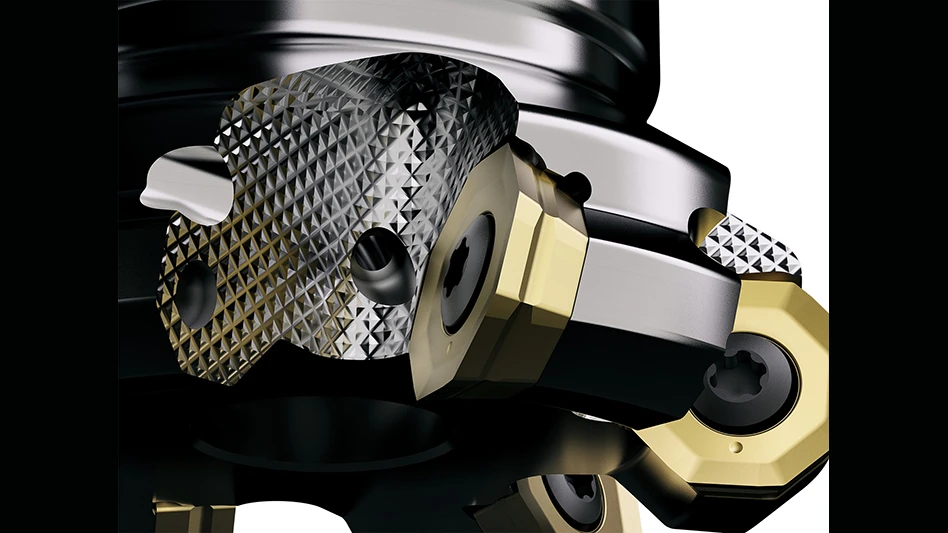

The HyperMach H4000 uses proven elements from Cincinnati's advanced line of Hyper-Mach vertical profilers, only in different orientation. The high-performance design features choice of 30,000rpm 60kW HSK63A spindle or 20,000rpm 85kW HSK100A spindle. The powerful high-speed spindles deliver high metal removal rates of 8,066.5cc/minute on aluminum plate or forgings.

Water-cooled motors power the table/pallet receiver at speeds up to 50m/minute. High-speed ballscrews drive the Y and Z axis, while the spindle carrier rotates at 150 deg/ second in A and C axis powered by permanent magnet torque motors – no gears, belts or mechanical drive elements to wear or replace. The H4000 comes standard with 96 tool automatic tool changer (HSK63A), field-expandable to 190 tool capacity.

IMTS BOOTH A-8218

MAG Cincinnati

Hebron, KY

cinmach.com

Explore the July August 2008 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Archer unveils Midnight Launch Edition

- AMETEK PDS' rapid-response tactical booster amplifiers

- BAE Systems expands Endicott operations to support aircraft electrification

- Frontgrade's Class L GaN DC-DC converter, EMI filter

- #39 - Lunch & Learn Podcast with EMUGE-FRANKEN USA and Okuma America

- Boeing selects Collins Aerospace ejection seats for F-15EX

- Exxelia's mica capacitors

- Embraer clinches firm order from Japan’s ANA Group