Hill Helicopters manufactures luxury light helicopters. The company’s team of more than 80 engineers develop and manufacture a complete aircraft from the ground up. To achieve this, the Rugeley, United Kingdom manufacturer has enlisted the support of leading manufacturers of machine tools, cutting tools, and ancillary equipment. When the company needed CAD/CAM technology trusted by the aerospace industry, it turned to OPEN MIND Technologies and its advanced hyperMILL CAD/CAM software suite.

Founder, Chairman, and Chief Engineer at Hill Helicopters, Dr. Jason Hill, says, “Hill Helicopters are designers, developers, and manufacturers of the HX50 5-seat turbine light helicopter. We’re bringing light helicopter manufacturing back to the U.K. for the first time in 50 years. To sell an effective general aviation light helicopter, you must match the price point with high-end supercars. To do that, you really can’t turn to the existing aerospace supply chain. So, we’ve had to develop a vertically integrated manufacturing strategy where we manufacture everything in-house from scratch.”

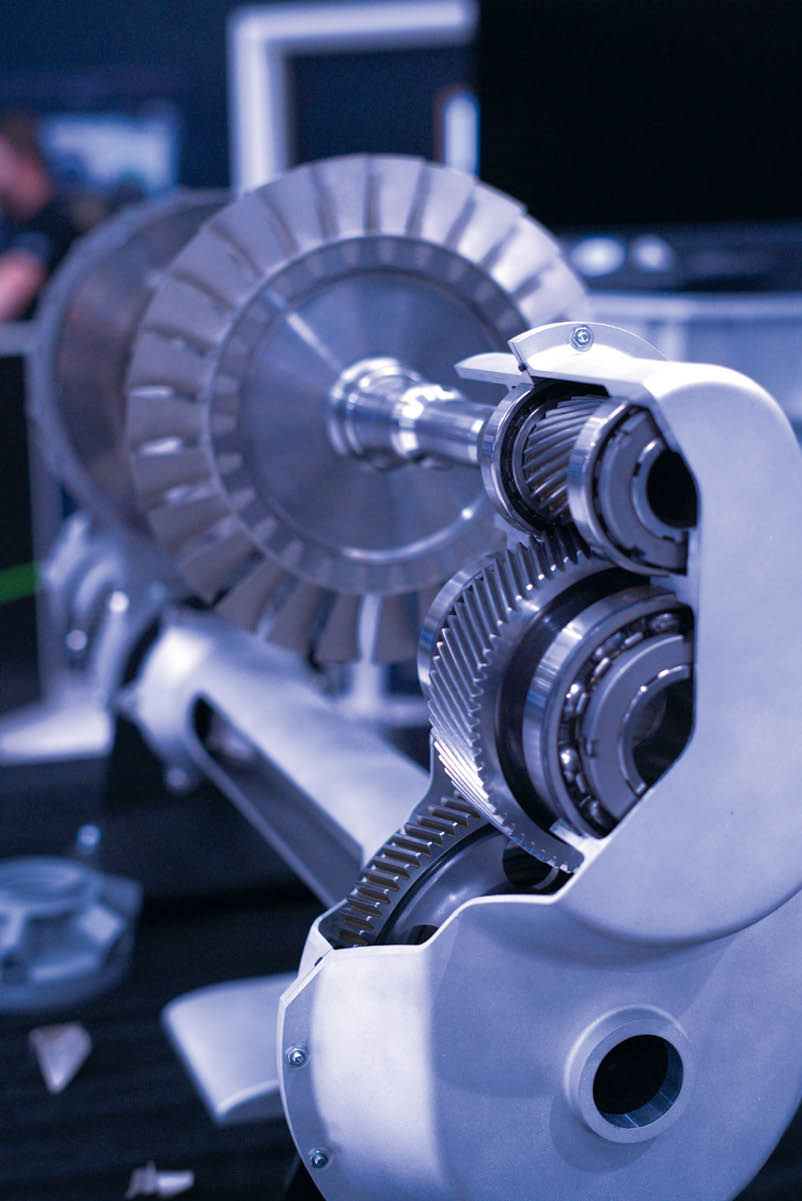

Explaining how the company has achieved this, Hill adds, “We’ve developed the entire machining and composites capability – for a whole aircraft, transmission system, and the gas turbine engine. That’s been an enormous undertaking. We have a group of technology partners that have helped take us through the learning curve and enabled us to machine parts, cast parts, and make composite components. OPEN MIND Technologies has been an instrumental knowledge and support partner, enabling us to program and manufacture complex machined components in a wide variety of materials.”

A growing relationship

Describing the start of the relationship between Hill Helicopters and OPEN MIND Technologies, Justin Talboys-Cotton from OPEN MIND says, “We were initially invited by Hill Helicopters to look at their compressor wheel, which is effectively an impeller. It was a challenging component with very small gaps. Since then, there’s been a wide variety of parts the company wanted to make. The relationship has grown, and as Hill Helicopters bought more equipment and machine tools, they’ve increased their use of hyperMILL. Being invited into Hill helicopters at such an early stage – before machines and programmers were here – has been really exciting, to be part of this helicopter development program and watching it grow.”

GA 2.0

Presently, Hill Helicopters is fast approaching 1,000 units in sales with 943 aircraft pre-ordered for delivery to 67 countries. It’s currently looking to invest in a new facility to accommodate its growth, and every month new milestones are being reached in bringing the project to rapid fruition. Hill Helicopters has pioneered a new approach to delivering and supporting safe, exciting, luxury private aircraft ownership at an affordable price, calling the new concept General Aviation 2.0 (GA 2.0) – an end-to-end ownership experience that’s entirely customer-focused.

It begins with a ground-up modern aircraft design while simultaneously meeting or exceeding the latest European Union Aviation Safety Agency (EASA) and U.S. Federal Aviation Administration (FAA) airworthiness requirements. Beyond this, GA 2.0 also provides an all-new, safe, and fully supported ownership experience. These factors ensure the new aircraft delivers low operating costs and maintains a stable high resale value, making personal helicopter ownership more attainable than before. For the aircraft, the Hill GT50 engine is a 400hp unit with a take-off power of 440hp (328kW) up to 3,048m (10,000ft), a cruise speed of 259km/h (161mph; 140kts) and a maximum range of 1,296km (700nm). The company is also manufacturing a commercial variant, the HC50. The differences between the HC50 and HX50 are price, time to market, and customization based on customer preferences (for example, color).

Speed counts

Hill says of the current stage of development, “Fundamentally, our sole objective is to get through the development of parts and subsystems as fast as possible. Almost everything we do on every single machine here is a first-off, a one-off. So, we must manage the risk of programmer error or machine crashes as we’re going through these development phases at a fast pace. The capabilities within hyperMILL are absolutely crucial to us being able to do that with minimum risk and the maximum confidence possible – as quickly as possible.”

OPEN MIND’s Talboys-Cotton adds, “The hyperMILL VIRTUAL Machining Optimizer enables the customer to execute functions such as rewinding automatically on a gantry mill. You program as usual even though the machine is performing complex processes. Having the digital twin setup via the Optimizer module automatically ensures the processes are collision-free and able to run within the machining envelope comfortably. I believe the main objective here in being efficient is managing the many parts and design changes involved with the components passing through the process chain for the first time. hyperMILL is enabling Hill Helicopters to really optimize their programs, first as prove-out for fit-for-function, but also to make sure the parts are going to be valid for the production environment.”

Hill adds, “We program milling and turning with hyperMILL and it’s absolutely instrumental for us to be able to rapidly develop hundreds of complex components in a wide variety of materials to extremely tight tolerances.”

On concluding the project, Hill says, “I’ve been dreaming about making this helicopter since I was a little boy, so to find myself 44 years later in a position where it’s becoming physical and real, where we’re not far from actually flying, is an amazing experience. The day-to-day requirements of building a helicopter and a jet engine from scratch are extremely demanding. However, seeing the joy in our staff and our 943 customers who are witnessing this becoming a reality and taking its first baby steps into flight more than offset that. It’s a journey that’s definitely been worth it.”

Hill Helicopters

Explore the May 2024 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- NASA-supported technology outfits Venus Aerospace hypersonic engine

- To the Smoothest Surfaces, Finishes, and Beyond | Okuma GA26W

- Extraordinary Starts Where Limits End | Okuma

- Satair, Champion Aerospace sign multi-year distribution agreement

- EMUGE-FRANKEN USA expands N. American solid carbide drill program

- AURA AERO unveils INTEGRAL R to the US market

- Creform Tite-Space AGV fleet

- Cyient Group, Deutsche Aircraft finalize multi-year contract