GKN Aerospace

Multi-technology Tier 1 aerospace supplier GKN Aerospace and KTH (the Swedish Royal Institute of Technology) will together develop electric fan technology for smaller regional aircraft. The project, to span more than 1.5 years, will study aerodynamic design, performance, noise, and manufacturing technology for a nested fan powered by electricity, either from batteries, hydrogen fuel cells, or conventional hybrid propulsion solutions.

The proposed propulsion solution with a nested fan instead of a conventional propeller offers significant advantages in three main areas: safety, noise level, and engine installation. By rapidly demonstrating fan technology for electric aviation, the EleFanT project will accelerate the pace of electric aviation development and position the participants for international aero-engine and aircraft development projects.

The project, which kicked-off in July 2021 and is supported by the Swedish Energy Agency, underpins GKN Aerospace’s sustainability goals, and will be delivered from its new Global Technology Centre in Trollhättan, Sweden.

Europe's aviation industry has set clear targets and adopted an ambitious roadmap to achieve net zero emissions by 2050.

"We are very positive about this initiative, which helps us to become part of the solution to aviation's climate challenge. We will benefit greatly from GKN Aerospace and KTH's long experience in turbomachines, lightweight construction, and advanced manufacturing technology. From an electrification and sustainability perspective the project is strongly aligned with our recently announced H2GEAR and H2JET programs." says Henrik Runnemalm, vice president of GKN Aerospace Global Technology Centre in Trollhättan.

Latest from Aerospace Manufacturing and Design

- November Lunch + Learn with Fagor Automation

- Able Aerospace SMS earns FAA acceptance

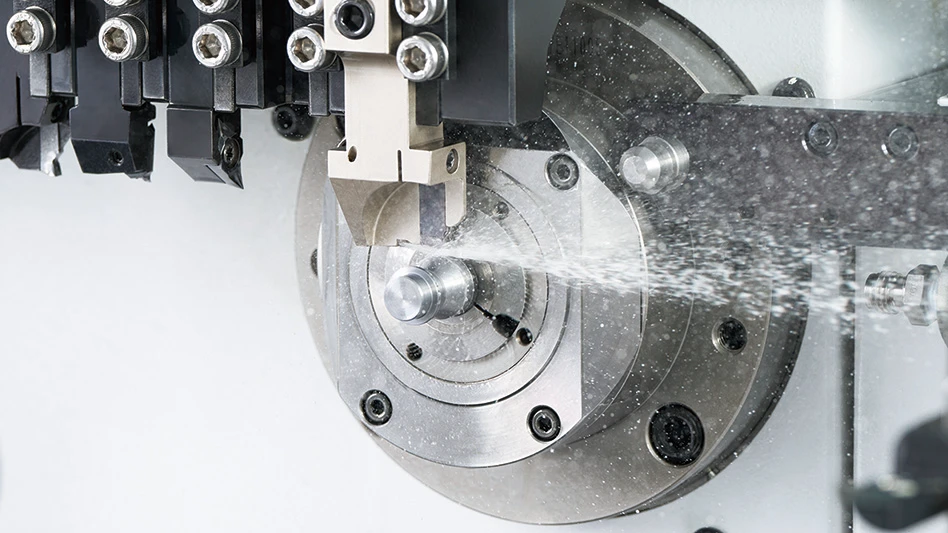

- Iscar's CERMILL endmills with ceramic round inserts

- IMTS 2024 Booth Tour: Okuma America Corp.

- Solar Atmospheres of Western PA gets Pratt & Whitney approval

- Tungaloy’s TungBoreMini drilling and turning tool

- 3 Questions with an Expert: Mitutoyo

- Optimize your manufacturing applications with the right metrology tools