Electroimpact

Morgan Hill, California – A joint development between Electroimpact, Toray Advanced Composites, and Janicki Industries has achieved a leap forward in the high-speed manufacture of large thermoplastic composite parts. The project has resulted in the development of automated, cost-effective processing technologies that can manufacture large-scale thermoplastic parts at high-speed deposition rates of up to 4,000" (100m) per minute.

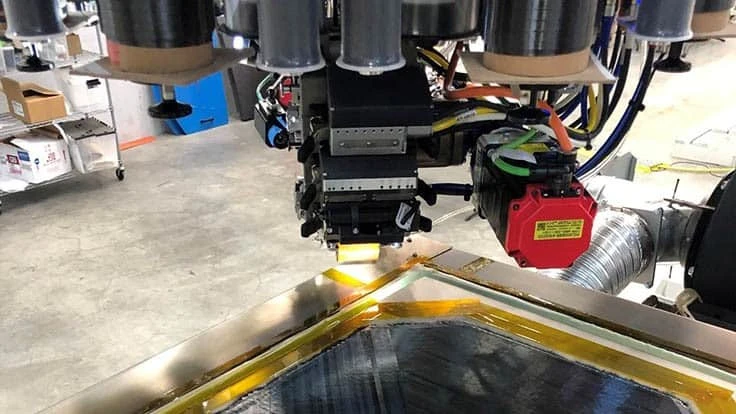

High-speed Automated Fiber Placement (AFP) equipment from Electroimpact has been enhanced for processing thermoplastic materials with a Variable-Spot-Size Laser heating system. This system uses a large range of processing temperatures for robust process control across individual tows to accommodate severe contours while enabling thermoplastic composite parts to be repairable during AFP lay-up, thereby reducing risk of wastage during part manufacture.

Processing speeds of up to 4,000ipm (100m/min) have been achieved with light or heavy tack levels to guarantee part geometry. “When these advancements are combined with increased AFP reliability, in-process real-time inspection and maintenance intervals, the resulting AFP 4.0 processing increases 4x to 6x current productivity,” says Michael Assadi, Chief Engineer at Electroimpact.

To maximize production efficiencies, the AFP layup is formed directly on to an out of autoclave heated lay-up tooling system, engineered by Janicki Industries, which is then fully consolidated in-situ, achieving a complete thermal process cycle in less than one hour. The tooling system is designed for scalability to accommodate parts that are too large for traditional heated press applications and achieves significantly faster cycle times than high temperature autoclaves.

“The key to this technology is rapid heating and cooling rates with edge-to-edge uniformity throughout the process” states Todd Chace, Director of Research and Development at Janicki, “Complete consolidation under vacuum bag only pressure is achieved by controlling the key stages of melt, flow, and crystallization with precise temperature control”.

Toray Cetex® TC1225 low melt PAEK (LMPAEK) uni-directional tape from Toray Advanced Composites was selected to further optimize processing. Proven to show best-in-class levels of impregnation, TC1225 LMPAEK enables the production of highly consistent, quality parts while also eliminating the need to wet-out fiber bundles during the consolidation cycle, allowing out of autoclave processing with near zero porosity. Combined with a relatively low processing temperature when compared to other PAEK-based systems, Toray Cetex TC1225 LMPAEK enables a faster layup speed while achieving comparable mechanical properties.

“Individually, each of these technologies represents a step forward in thermoplastic composite processing. When combined, a major leap in large-scale, rapid part fabrication is achieved, underlining the importance of partnership across the value chain to advance the adoption of thermoplastic composites into industry,” adds Steve Cease, VP Technology & Strategic Marketing at Toray Advanced Composites.

Latest from Aerospace Manufacturing and Design

- GE Aerospace secures Air Force engine contract

- Thomson Industries' online sizing and selection tool

- #53 - Manufacturing Matters - 2024 Leaders in Manufacturing Roundtable

- Join us for insights on one of the hottest topics in manufacturing!

- You can still register for March’s Manufacturing Lunch + Learn!

- Ohio creates Youngstown Innovation Hub for Aerospace and Defense

- Tormach’s Chip Conveyor Kit for the 1500MX CNC Mill

- How to Reduce First Article Inspection Creation Time by 70% to 90% with DISCUS Software