The iSpeed5 is a fully tool changeable, high speed electric spindle system. As a 350W (0.5hp) variable speed system, it is available in 60,000rpm or 80,000rpm max. speeds. The controller can run multiple motor spindles at different parameters and fully integrates with a machine tool CNC control. The system eliminates the need for external motor cords or air lines, allowing for continuous lights-out high-speed machining. The motor spindles connect to the controller through a constant clean stop block. The iSpeed5 delivers less than 1µm TIR. Spindles are available in most CAT, BT, and HSK tapers. NSK America Corp.

CT metrology system

New features have been added to the 225kV microfocus X-ray computed tomography (CT) system, including:

Rotating.Target 2.0: More efficient cooling enables 3x smaller focal spot size for clearer imaging; data quality, image resolution maximized; doubles running time before preventive maintenance is required

Half.Turn CT: Novel method for nearly halving the angle through which a specimen rotates during the X-ray cycle, speeding the process without losing image quality

Motorized focal spot to imager distance (FID) adjustment: No need to increase X-ray power; shorter FID may be selected, giving faster scan times or a higher signal-to-noise ratio when using low-energy X-ray power

Local.Calibration: Allows rapid, repeatable, automated calibration of voxel size at any CT scan position

Auto.Filament Control: Controls X-ray source, doubling lifetime of the filament, lowering cost, increasing system uptime without losing microfocus resolution

Quick.Change plug-and-play filament cups: Easily repeatable process that reduces downtime, eliminates human error

Hydraulic vise

The 130mm double-acting hydraulic vise with high holding forces offers quick clamping and repeatability for improved speed and part tolerance. The vise comes with multiple mounting patterns, jaw options, and easily accessible plumbing and maintenance ports.

Positioning the jaws just outside the workpiece minimizes travel when clamping, and combined with hydraulic workholding speed, reduces clamping and unclamping operations to 1 second. These repeatable operations lead to measurable machine uptime and productivity increases, especially for high-mix, low-volume manufacturers.

Hydraulic pump kits include everything to hook up and control a vise including the compact pump – mounted horizontally or vertically – and a manual or solenoid zero leak valve to control clamping.

LED profile projector

The PJ-Plus series of profile projectors uses LED lighting, provides reliable measurements, and offers stable dimension and angle measurements in harsh environments.

The LED illumination source eliminates the need for a cooling fan in the main unit, decreasing the entry of oil, mist, and dust into the measuring instrument. It also uses a more efficient stepless illumination control instead of the conventional 2-step illumination adjustment system, allowing for lighting levels to be set to suit the surface texture and workpiece color.

Counterbalance support hinge

The CB counterbalance support hinge can be used in tandem with the CB counterbalance hinge, for applications where the counterbalance hinge supports full torque requirements of the panel or lid.

It enables ergonomic lifting and position control when combined with a CB counterbalance hinge by using stored energy to balance the weight distribution of a lid or panel. Hinges are fully adjustable, allowing opening and closing performance to be tailored to the application’s requirements.

With robust, all-aluminum construction, the hinges offer improved corrosion resistance and consistent performance in hot and cold temperatures and increased life cycle, reducing the need for maintenance.

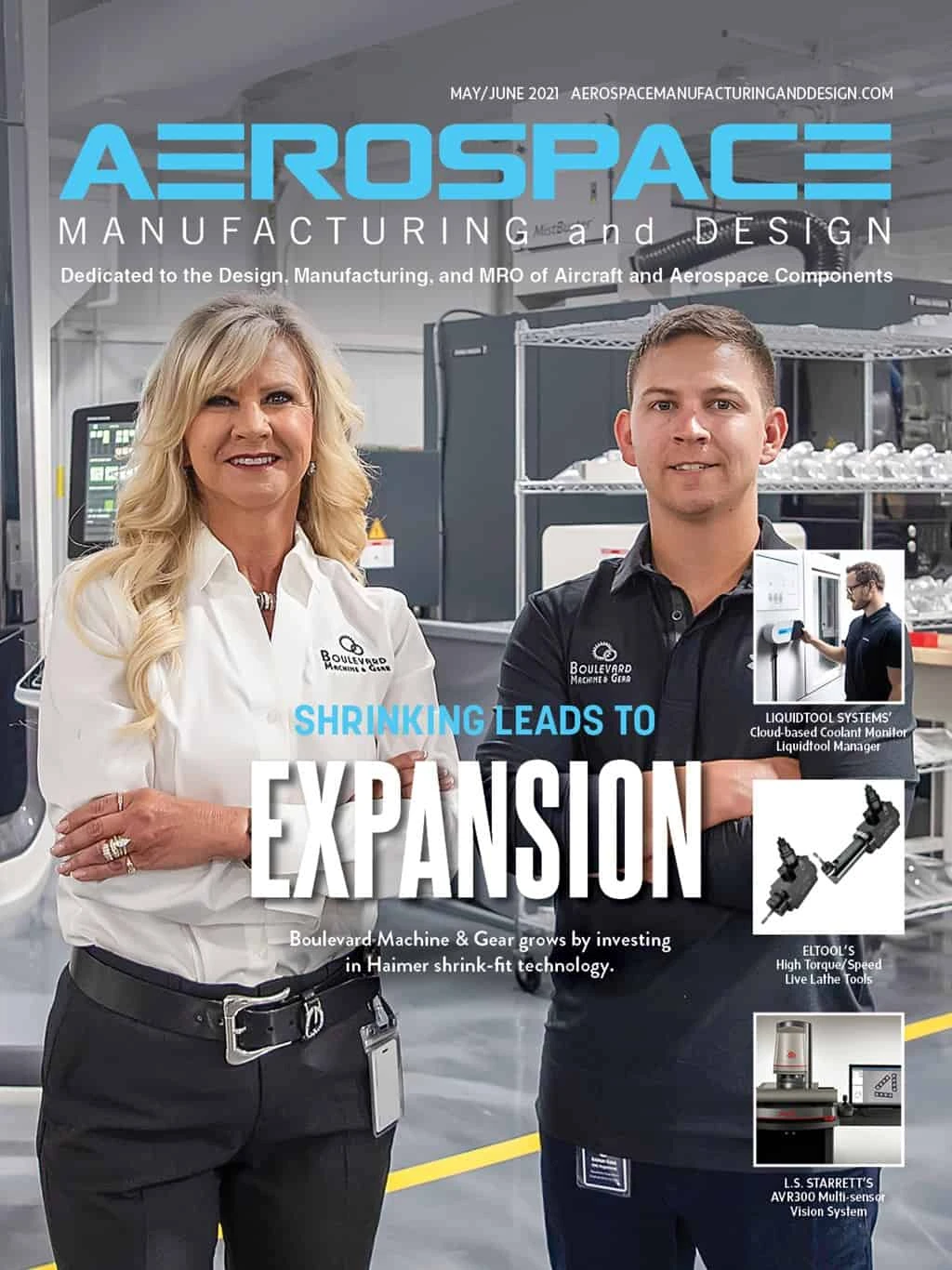

Explore the May June 2021 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Taiwan’s China Airlines orders Boeing 777X passenger, freighter jets

- Reamer re-tipping extends life of legacy tooling

- Revitalizing the Defense Maritime Industrial Base with Blue Forge Alliance

- Safran Defense & Space opens US defense HQ

- Two miniature absolute encoders join US Digital’s lineup

- Lockheed Martin completes Orion for Artemis II

- Cylinder CMMs for complex symmetrical workpieces

- University of Oklahoma research fuels UAS development