Series 319SW twin cutters create 0.787" to 8.000" holes and provide heavier cuts for greater efficiency.

Designed for heavy-duty rough boring and semi-finishing, the tool eliminates multiple passes on the same bore and allows smaller tools to create a starting hole. Cast parts sometimes have more material to remove than expected, so balance- or step-cutting with the same boring head minimizes tooling and cycle times.

Insert holders with an adjustable insert cartridge allow the bore to be completed and produce the blend angle in one pass, eliminating the need for follow-up tooling. Back boring holders can eliminate expensive dedicated special tools, and face grooving holders allow plunge cutting versus milling, speeding the process while producing a better surface finish.

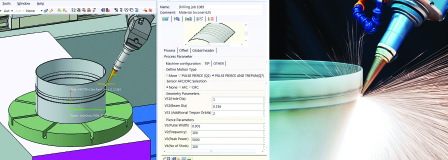

Laser processing software

Fastrim CAD/CAM software allows users to model parts, design part fixtures, and define process paths and feature locations. It supports 2D and 3D laser welding, drilling, and cutting.

The software supports the Laserdyne 795, Laserdyne 430, and Laserdyne 606D systems, allowing welding (with and without wire feed), percussion drilling, hole trepanning, and cutting using quasi continuous wave (QCW) and continuous wave (CW) lasers.

Z-axis measuring electronic microscope

The ZDM-3 Z-axis electronic depth- measuring microscope features an LED co-axial illuminator to focus on the top or bottom of the part being inspected. The illuminator has a green filter that adjusts to control light, color, and intensity.

It can measure heights of the bonded portion of lead wire, wafer bump, lead frames, and solder on semiconductors. The microscope also measures step heights of hybrid integrated circuits and terminal steps on multi-layer PC boards, as well as minute cracks and engraving depth.

The ZDM-3 can be fitted with a video adapter to increase magnification range and provide greater accuracy.

Machine vision lighting

SmartVisionLink wireless connectivity allows remote adjustment of key parameters for six or more compatible lights using a smartphone app. Users can remotely manage, configure, and digitally store the intensity of multiple LED sources or zones in a multi-zone light via the app’s controls, allowing lights to be calibrated with others to ensure a homogeneous surface light pattern.

Explore the May 2019 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Ralliant to establish global headquarters in North Carolina

- Philatron MIL-DTL-3432 military cables

- Beyond Aero refines its hydrogen-electric light jet

- Americase's advanced protective solutions

- Social media - what are your thoughts

- GE Aerospace secures Air Force engine contract

- Thomson Industries' online sizing and selection tool

- #53 - Manufacturing Matters - 2024 Leaders in Manufacturing Roundtable