With rising material costs, government regulations, and customers resisting price increases, there is no room for waste in the aerospace metal fabrication supply chain.

With rising material costs, government regulations, and customers resisting price increases, there is no room for waste in the aerospace metal fabrication supply chain.

Aerospace OEMs once had the time, margins, and procurement staff to afford two-month lead-times for fabricated metal components subcontracted to vendors, each taking a slice of profit and adding weeks of lead time. That is no longer the case.

Aerospace OEMs’ latest competitive advantage is one-stop precision metal fabrication, which streamlines the supply chain. Full-service metal fabrication under one roof can not only cut cost, lead time, and improve quality but also satisfy rush orders and just-in-time (JIT) requirements.

Optimizing the supply chain

Traditionally, aerospace OEMs have relied on metal suppliers to provide parts using processes such as cutting, drilling, grinding, and polishing. Secondary operations such as finishing, forming, coating, welding, and assembly were completed by other companies, usually at different locations.

The problem with outsourcing to multiple vendors – all with their own processes, inspection, lead-times, shipping, freight costs and profit mark ups – is that it can inflate the cost of doing business. It can also delay orders weeks or months to the point of losing the order, particularly if errors occur and subcontractors engage in the finger pointing-blame game, rather than fixing the problem and expediting the order.

The more layers of vendors involved, the slower the precision metal fabrication process, and worse the transparency. If you have to juggle several subcontractors with limited capabilities to fill a large rush order, any delay can snowball. One delay will impact the next vendor, since most vendors only understand small pieces of the puzzle.

Recognizing the need to optimize the aerospace OEM supply chain, some custom metal fabricators have gradually expanded their in-house capabilities – upgrading their facilities and equipment to essentially act as a full-service metal fabrication company.

To be a one-stop fabrication facility means delivering additional fabrication, finishing, and assembly operations under one roof. Many metal parts manufacturers claim to have additional capabilities, but in reality they simply farm it out to others.

Shipping aerospace products to multiple vendor locations increases the risk of transport damage and quality problems, if not properly inspected at each step. This applies to metal part suppliers that purchase other companies or capabilities but do not bring them under one roof. This gives them a little more control, but does not eliminate the inefficiencies of cost, transport, and lead times moving products between different geographic locations.

.jpg) Getting parts from a source that does the work under one roof can help meet commitments, even large rush orders with a single point of contact. It is much faster to move components to value-added processes within the same building than to ship them to vendors across the state or country.

Getting parts from a source that does the work under one roof can help meet commitments, even large rush orders with a single point of contact. It is much faster to move components to value-added processes within the same building than to ship them to vendors across the state or country.

It is possible for OEMs to save by eliminating unnecessary layers of subcontractor profit, shipping, packaging, accounting, and follow up. Further savings are possible by working with a company that can purchase raw materials at mill-direct pricing.

Smaller machine shops typically buy in small quantities from metal service centers that include a middleman mark-up. Larger metal fabricators have the buying power to purchase direct from the mill. These savings are then passed along to the OEM.

For aerospace OEMs, there is one additional competitive advantage to working with a one-stop shop: simplifying quality auditing. Instead of having to track and audit several vendor subcontractors, it is simpler to monitor one full-service vendor.

Summit Steel and Mfg.

www.summitsteelinc.com

About the author: Gary Romig is founder and CEO of Summit Steel and Mfg., a metal component fabrication provider located in Reading, Pennsylvania. He can be reached at 610.921.1119.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

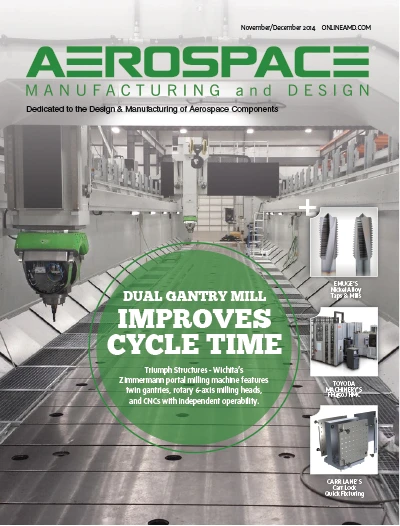

Explore the November December 2014 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Beyond Aero refines its hydrogen-electric light jet

- Americase's advanced protective solutions

- Social media - what are your thoughts

- GE Aerospace secures Air Force engine contract

- Thomson Industries' online sizing and selection tool

- #53 - Manufacturing Matters - 2024 Leaders in Manufacturing Roundtable

- Join us for insights on one of the hottest topics in manufacturing!

- You can still register for March’s Manufacturing Lunch + Learn!