The VZ500LH was created to handle to the growing demand for large capacity wire EDM machines featuring extreme height capability. This type of machine is often suited for aerospace parts such as turbine hubs, airfoil vanes, instrument panels, and mold cores.

The VZ500LH was created to handle to the growing demand for large capacity wire EDM machines featuring extreme height capability. This type of machine is often suited for aerospace parts such as turbine hubs, airfoil vanes, instrument panels, and mold cores.

Introduced at IMTS 2014, the VZ500LH features a 17.2" Z-axis cutting capacity. Additional standard features include a Super-Jet automatic wire-threader (AWT), wire-tip disposal unit, anti-electrolysis circuit, and dielectric cooling unit (chiller).

The machine’s linear motor axis drives are coupled with glass scales on the X, Y, U, and V axes to ensure precision cutting and positioning accuracy. The drives have no backlash and are backed by a 10-year positioning accuracy guarantee.

The control incorporates collision protection to prevent against operator error. This technology constantly monitors axis load, and when voltage exceeds a pre-determined limit, the machine will stop and give an error message. With the rigid linear motor drive system, the machine has no mechanical connection between the motor drives and the table, unlike ballscrew drives.

The control also features automatic machining condition selection. This database contains details on the best conditions for a particular wire diameter, workpiece material, or workpiece thickness to optimize machining results. Operators can use conditions provided by Sodick or add their own conditions.

Ceramic components are used in the upper and lower arms, base plates, pedestals, workstand, table, and other critical parts. Ceramics offer a very low thermal expansion coefficient (less than one-third that of cast iron), high rigidity, and resistance to aging.

The VZ500LH features a large capacity worktank that includes a vertical access door for ergonomic accessibility. Since the door slides down, the machine requires less operating space. The no-drip feature keeps shop floors clean, maintaining a safe work environment.

Download a flyer at http://bit.ly/1teZtKm.

Sodick Inc.

www.sodick.com

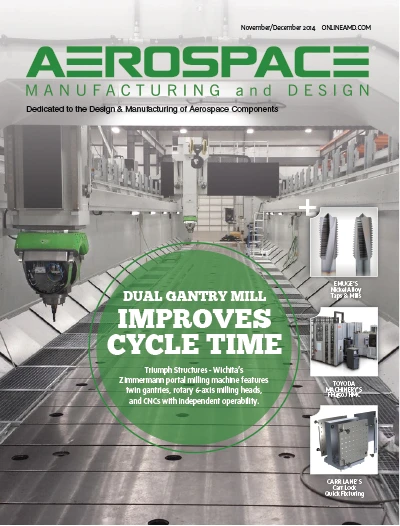

Explore the November December 2014 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Revitalizing the Defense Maritime Industrial Base with Blue Forge Alliance

- Safran Defense & Space opens US defense HQ

- Two miniature absolute encoders join US Digital’s lineup

- Lockheed Martin completes Orion for Artemis II

- Cylinder CMMs for complex symmetrical workpieces

- University of Oklahoma research fuels UAS development

- Motorized vision measuring system

- Everyone's talking tariffs