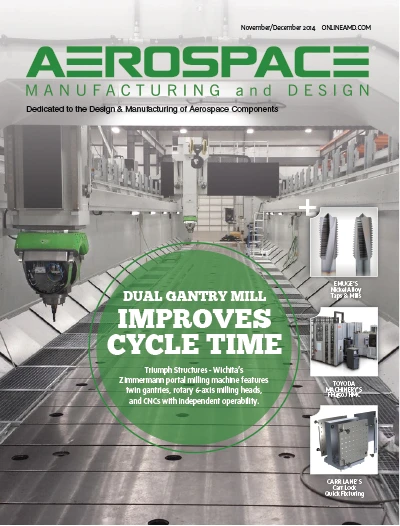

Triumph Structures - Wichita, a Triumph Group company, brought a unique challenge to the engineers at Zimmermann in Novi, Michigan, and the solution has yielded various benefits to this major supplier of aerospace components. Harry Thurmond, president at the Kansas-based Triumph location explains, “We had requirements for spars and stringers that often reached 22ft in length, but we also do a variety of production jobs on smaller sections such as bulkheads. This creates the need for fast, reliable, and adaptable machine tools.”

Triumph Structures - Wichita, a Triumph Group company, brought a unique challenge to the engineers at Zimmermann in Novi, Michigan, and the solution has yielded various benefits to this major supplier of aerospace components. Harry Thurmond, president at the Kansas-based Triumph location explains, “We had requirements for spars and stringers that often reached 22ft in length, but we also do a variety of production jobs on smaller sections such as bulkheads. This creates the need for fast, reliable, and adaptable machine tools.”

Triumph considered a variety of options to expand on the capabilities of its existing milling machines, some of which had been in operation for decades.

Triumph’s Wichita operation specializes in complex, high-speed, monolithic precision machining and sub-assembly of aluminum and titanium structural airframe components, often with wall thicknesses down to 0.02". Currently, 21 individual 5-axis machining centers are resident in this facility, with a maximum length of 960". More than 20 other 3-axis and 4-axis machines complete the machining capability for aluminum structures. Triumph runs a gamut from build-to-print precision machining of aluminum and hard metal, small-to-large parts – especially aircraft wing spars, skins, bulkheads, and landing gear components.

Triumph had the machine capabilities at Wichita, but it needed a particular machine that could be used to serve multiple purposes. First, it had to machine very long parts with volumetric compensation to manage material expansion and the tool-tip position over a very long cutting cycle, often multiple days. The aerospace supplier has extensive experience in this area; however, engineers thought that a single machine might also be capable of running multiple smaller parts or operate in twin fashion, occasionally using the entire machine bed with both heads working the same part in tandem. The latter scenario would demand close attention to collision avoidance between the gantries, and consistency of surface machining at the points where the twin machining heads intersected.

To achieve Triumph’s requirements, Zimmermann, its longtime partner and portal machine supplier, modified its popular FZ100 machine with twin gantries, each equipped with a three-rotary-axis head and independent Siemens Sinumerik 840D sl CNC.

Zimmermann Inc. President Matthias Tockook notes, “We had a variety of machine styles available, but the best solution was a head with three rotary axes, A-B-C integrated in a forked milling head. This provided simultaneous 6-axis cutting in a very compact design, with no pole position, less overall axis rotation, a constant feed rate capability, and improved surface quality.”

The individual head machining time scenario was further detailed. If the maximum time was achieved using an A- and C-head with infinite C-axis, the alternative A-B-C integrated rotary axis head could accomplish the same work in 25% of that time.

The individual head machining time scenario was further detailed. If the maximum time was achieved using an A- and C-head with infinite C-axis, the alternative A-B-C integrated rotary axis head could accomplish the same work in 25% of that time.

In designing the final work envelope and machine structure, Zimmermann engineers determined the best solution was a removable breakwall built into the midpoint of the machine bed that would allow completely independent operation of the entire machine, literally running as two machine tools in one. When removed, the machine bed could accept parts up to 960" in length and process them using the twin heads working in tandem and monitored for total collision avoidance by the two CNCs onboard.

The volumetric compensation feature of the Siemens CNC bases machining upon the actual tool-tip position, so the point of intersection for the twin heads was easily addressed and resolved. Surface integrity on the workpiece would be preserved, while machine and operator safety would remain paramount.

The machine was built throughout a period of 18 months. Parts were sent to Zimmerman to be fully tested prior to being erected onsite at Triumph.

According to Thurmond, the Zimmermann head design provides significant advantages in speed on the typical peaks and pockets found in aerospace structure machining, working in tandem with the look-ahead feature on the CNC. “It slows down and speeds up in anticipation of the next required surface contour. Over long run times, this can translate into an improvement of 35% or better, because there is no deburring or polishing required. We routinely get better than a 125rms finish on inside pocket surfaces and up to a 32rms on the outside of the Series 7000 aluminums we run. Combined with the flexibility of the machine to work a single structure or individual workpieces simultaneously, we have been quite satisfied with the results to date.”

On longer runs, Thurmond says the chilled coolant used on the Zimmermann is helpful in minimizing thermal expansion of the material, a critical factor in long run machining work. Additionally, the machine produces workholding and fixturing devices. Lastly, Thurmond notes that the Zimmermann machine is equipped with test probes, so it can be used as a coordinate measuring machine to measure workpieces in process.

On longer runs, Thurmond says the chilled coolant used on the Zimmermann is helpful in minimizing thermal expansion of the material, a critical factor in long run machining work. Additionally, the machine produces workholding and fixturing devices. Lastly, Thurmond notes that the Zimmermann machine is equipped with test probes, so it can be used as a coordinate measuring machine to measure workpieces in process.

The 3-axis head avoids the pole position of the traditional 2-axis A-C head at A = 0°. In this Zimmermann head design, the B-axis moves ±15° inside a rigid curved guideway for handling the inner sloping and especially the pockets typically found on aero structures, so simultaneous 6-axis machining is achieved with high surface finish integrity.

The new machine is further equipped with a stationary clamping table, fixed mounted side walls, and DemTec composite fill on the base and side walls for enhanced stability and vibration damping.

Backlash-free drives with rack-and-pinion mechanisms are sealed from contamination and guided on both sides. All axes have feed rates to 60m/min and accelerations to 4m/sec2. Each head can access a 60-position toolchanger on the machine.

For communication of data from the machine, Triumph integrates the CNCs into its Ethernet network via DNC and hard-wiring. Through a remote monitoring feature on the Sinumerik 840D sl CNC, Zimmermann can also maintain awareness of all conditions on the machine in real-time.

Thurmond notes, “We had grown steadily over the last decades since our incorporation of 5-axis work in the 1990s and were ready to jump to a new level of competence for our customers, who represent the top players in both commercial and military aircraft, making Triumph Structures – Wichita a more value-adding supplier. Our part length capability had been 22ft here in Wichita, and we were committed to expanding it, to compete in the 40ft to 80ft part ranges. As with all aerospace structure machining, material removal rates are extremely high. We can start with a 5,600 lb workpiece that ends up at 100 lb, for example.” He adds that the machines at Triumph must be robust with high-precision control of the cutting cycles, which often run for multiple days.

Thurmond notes, “We had grown steadily over the last decades since our incorporation of 5-axis work in the 1990s and were ready to jump to a new level of competence for our customers, who represent the top players in both commercial and military aircraft, making Triumph Structures – Wichita a more value-adding supplier. Our part length capability had been 22ft here in Wichita, and we were committed to expanding it, to compete in the 40ft to 80ft part ranges. As with all aerospace structure machining, material removal rates are extremely high. We can start with a 5,600 lb workpiece that ends up at 100 lb, for example.” He adds that the machines at Triumph must be robust with high-precision control of the cutting cycles, which often run for multiple days.

Commenting on the CNC selection, Tockook observes, “With all the challenges we had on this machine, including the axes of motion, the integration of the twin gantry movements, the substantial safety factors involved and the need for independent and also co-dependent gantry operations, we quickly determined that only twin Sinumerik 840D sl CNCs could handle this job.”

The machine built for Triumph also includes Siemens servo motors and drives plus Fischer spindles running at 73kW (95hp) and operating at 27,000rpm. Siemens Industry Inc.

Drive Technologies — Motion Control (Machine Tool)

www.usa.siemens.com/cnc

Zimmermann Inc.

www.zimmermann-inc.com

Triumph Structures - Wichita

www.triumphgroup.com

Explore the November December 2014 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- NASA-supported technology outfits Venus Aerospace hypersonic engine

- To the Smoothest Surfaces, Finishes, and Beyond | Okuma GA26W

- Extraordinary Starts Where Limits End | Okuma

- Satair, Champion Aerospace sign multi-year distribution agreement

- EMUGE-FRANKEN USA expands N. American solid carbide drill program

- AURA AERO unveils INTEGRAL R to the US market

- Creform Tite-Space AGV fleet

- Cyient Group, Deutsche Aircraft finalize multi-year contract