NCSIMUL CAM delivers agile CNC programming to streamline the current CAM process and provides flexibility on the shop floor. Fully integrated in the new unified NCSIMUL Solutions V10 platform (including NCSIMUL Machine, NCSIMUL Tool, and NCSIMUL DNC), it embodies Spring Technologies’ response to today’s issues in CNC machine programming: removing the typical organizational method of tool path generation (CAM), post-processing, G-code verification and simulation, and streamlining the conventional CNC programming process.

NCSIMUL CAM delivers agile CNC programming to streamline the current CAM process and provides flexibility on the shop floor. Fully integrated in the new unified NCSIMUL Solutions V10 platform (including NCSIMUL Machine, NCSIMUL Tool, and NCSIMUL DNC), it embodies Spring Technologies’ response to today’s issues in CNC machine programming: removing the typical organizational method of tool path generation (CAM), post-processing, G-code verification and simulation, and streamlining the conventional CNC programming process.

Primary benefits to users will be significant cost savings and optimal use of CNC machines because of the flexible programming capability.

NCSIMUL CAM directly generates verified and optimized CNC programs, while factoring in the physical resources available on the shop floor, including tools, cutting conditions, kinematics, and machine controllers.

With this new solution CAM data (APT neutral file / CL-data) and existing CNC programs can be used easily to generate a valid new CNC program in just a few clicks for another machine using different kinematics and controller. This will enable manufacturers to adapt their existing programs to new resources when retrofitting a machine, buying a new one, or when a machining process is repurposed. With a conventional CAM process (CAM-post-processor-machining simulation), this task could take hours, even days. With NCSIMUL CAM, these times reduce to minutes.

Similarly, if the target machine initially planned for the CAM program is no longer available, it will take just one click with NCSIMUL CAM to switch programming to another machine – whatever complexity, kinematics, or type of controller.

Because of the integration of the NCSIMUL Tool database, NCSIMUL CAM provides a direct access to 3D tool data and cutting conditions and automatically reconfigures the tool magazine, providing manufacturers with the level of flexibility they need to achieve rapid switching of scheduled production from one CNC machine to another.

Spring Technologies

www.springplm.com

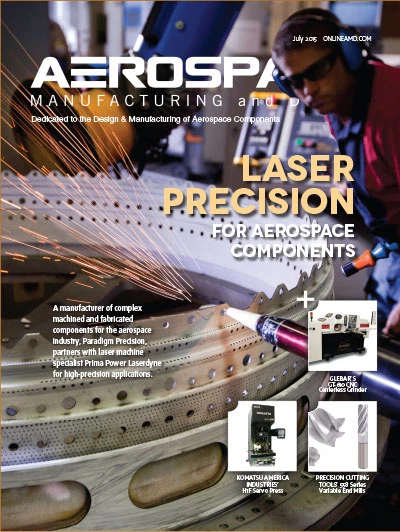

Explore the July 2015 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Piper Aircraft receives its largest ever domestic trainer order

- Miniature, high force-to-size linear voice coil servo motor

- MagniX, Robinson to develop battery electric R66 helicopter

- Zero-point clamping modules

- Hartzell electric engine propeller earns FAA approval for AAM

- Thin profile flame and thermal barrier

- Guill Labs offer materials and extrusion testing

- High production vertical honing systems