1U power supply rack, dual 3kW outputs

1U power supply rack, dual 3kW outputs

Built to house high-efficiency power supplies, the HFE1600D1U rack allows users to install supplies with different output voltages on either side of the rack’s split power bus. Measuring 1U in height, this new design allows for more flexibility when creating hot-swappable power architectures for data centers, wireless base stations, industrial automation, telecommunications, RF power amplifiers, network equipment, storage systems, and distributed power architectures.

Each half of the rack is capable of delivering 3,040W, for a total of 6,080W. For higher power architectures, up to two power racks containing up to eight HFE1600 series power supplies can be zero-stacked, requiring no space between racks.

HFE1600 series power supplies are available in standard output voltages of 12VDC, 32VDC, 24VDC, and 48VDC. Outputs are user adjustable. Each HFE1600 supply has two variable-speed cooling fans and can operate from -10°C to 70°C. An integrated keying system ensures that the correct HFE1600 is inserted where multiple voltages are used within a system.

All HFE1600 series hot-swap, front-end power supplies comply with EN55022 and FCC Class A radiated and Class B conducted emissions, and meet IEC61000-4 immunity.

Specifications

- Input voltage range

- 85VAC - 265VAC, 47Hz - 63Hz

- Input current (max.)

- 100/230VAC 14.2/8.1A

- Inrush current <35A

- Power factor correction - Meets EN61000-3-2, PF > 0.98 at full load

- Temperature coef?cient <0.02%/°C

- Overcurrent protection 105% - 120%

- Overvoltage protection 110% (tracking). Cycle AC to reset or utilize remote on/off

- Overtemperature protection – Shutdown with automatic reset; warning signal provided

- Hold up time >10ms, 100/230VAC input, 80% loading

- Leakage current < 0.75/1.5mA 100/230VAC, 60Hz

For more specs, visit http://bit.ly/1g06C9T.

TDK-Lambda

www.us.tdk-lambda.com/lp

Metal-to-plastic part conversions

Metal-to-plastic part conversions

The continued advances in high performance plastic technologies have allowed conversions of an increasing number of traditional metal parts to high-performance plastic. Replacing aluminum components with Polyphenylene Sulfide (PPS), for example, reduces weight and cost. Increased reliability through corrosion resistance also cuts costs. The company reviews each application ensuring the design and material selected are best suited for their intended application. When design is finalized, components are tested using finite element analysis (FEA) so that their thickness is optimized, eliminating costly excess plastic.

Metal-to-plastic conversion benefits

- Reduced weight

- Increased corrosion resistance

- Reduced development time

- Lower costs

- Decreased time to market

Minnesota Rubber and Plastics

www.mnrubber.com

High-g, triaxial, piezoresistive shock accelerometers

High-g, triaxial, piezoresistive shock accelerometers

The Endevco model 7284 series, a family of lightly damped, high-g, triaxial, piezoresistive shock accelerometers, is designed for high-g data recorders and other extreme-g applications. These rugged sensors, available in 20,000g and 60,000g ranges, offer survivability and low power consumption.

Sharing the same footprint, bolt pattern, and survivable sensing system of company’s single-axis 7280A series, the 7284 makes high-g shock measurements across three mutually perpendicular axes. With a frequency response extending down to DC (steady state), it can measure long-duration transient shocks.

Model 7284’s design incorporates three sensors mounted in a triaxial arrangement within a single housing. Each axis features a piezoresistive MEMS sensor with light gas damping to attenuate resonant amplitudes and prevent breakage in overload conditions. Because units are only lightly damped, they still respond to fast rise times and short duration shock motion. All sensing elements are manufactured in-house at a ISO9001-certified MEMS facility in Sunnyvale, Calif.

Screw-mount installation with factory controlled and tested cross-axis performance makes the model 7284 easier and more effective to install than three single-axis accelerometers with a mounting block. The sensor also features a robust, eight-conductor cable designed to withstand repeated high-g shock acceleration inputs. Input voltage of 5V and cable length of 48" are standard, but both are easily configured to customer requirements.

Recommended accessories include model 126 three-channel DC bridge amplifiers, model 136 three-channel signal conditioners, and model 436 DC differential voltage amplifier.

Meggitt Sensing Systems

www.meggittsensingsystems.com

www.endevco.com

Interconnect solutions

Interconnect solutions

Due to growing market demands for weight saving, EPXB2 with M and J plating has been developed as a lightweight alternative to EPXB2 with N plating. The connectors can withstand temperatures up to 125°C and 175°C, allowing users to adapt this solution to the aircraft area where it will be installed. Users can choose the most effective solutions for weight and cost savings.

EPXB2 with M and J plating are fully intermateable and interchangeable with EPXB2 with N plating and with themselves, using the same inserts, accessories, and panel mounting.

Specifications

- Up to 24% weight saving

- Temperature range: -65°C to 175°C

- Backwards compatibility with existing EPXB2 shells

- Compliant with EN4644 standard

Radiall USA Inc.

www.radiall.com

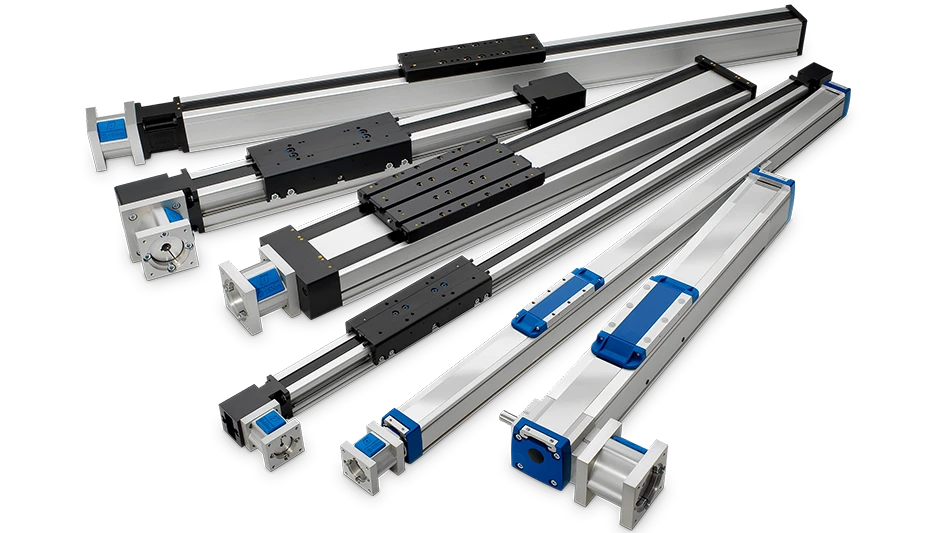

Small NEMA motor stepper gearboxes

Small NEMA motor stepper gearboxes

The SureGear PGCN series of stepper gearboxes is a choice for stepper and other motion-control applications requiring a NEMA-size input/output interface.

Available in NEMA 17, 23, and 34 sizes and gear ratios of 5, 10, 25, 50, and 100:1, SureGear stepper gearboxes are designed with a nominal speed of 3,500rpm and maximum input speed of 6,000rpm. Additional features include a low backlash of 30 arc-min or less, and a 20,000 hour service life.

The PGCN series is an accurate, high-performance solution for material handling, pick and place, automation, packaging, and other motion control applications requiring a NEMA input/output. While SureGear planetary gearboxes can be mounted in any orientation, they are not designed for back driving.

These gearboxes require no additional lubrication for the life of the unit and hardware is included for mounting to SureStep stepper motors. Optional shaft bushings are available for mounting to other motors.

For more information on the SureGear PGCN series stepper gearboxes, visit: http://bit.ly/1iSXXpA.

AutomationDirect

www.automationdirect.com

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Explore the March 2014 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Drop in for an interactive webinar on automation in manufacturing

- SW’s wing rib technology for the aerospace industry

- Mach Industries launches Mach Propulsion

- Murata Machinery USA's MT1065EX twin-spindle CNC turning center

- Electra reaches 2,200 pre-orders for its Ultra Short aircraft

- Heule's DL2 tooling for deburring of small bores

- Ralliant to establish global headquarters in North Carolina

- Philatron MIL-DTL-3432 military cables