A machine-learning (ML) algorithm developed at Sandia National Laboratories could provide aerospace and other industries a faster, more cost-efficient way to test bulk materials.

The technique was published recently in the scientific journal Materials Science and Engineering: A.

Production stoppages are costly. So, manufacturers screen materials such as sheet metal for formability before use to make sure the material will not crack when stamped, stretched, and strained as it’s formed. Companies often use commercial simulation software calibrated to the results of various mechanical tests, says Sandia scientist David Montes de Oca Zapiain, the lead author on the paper. However, these tests can take months to complete.

While high-fidelity computer simulations can assess formability in only a few weeks, companies need access to a supercomputer and specialized expertise to run them.

Sandia has shown ML can dramatically cut time and resources to calibrate commercial software because the algorithm doesn’t need information from mechanical tests or a supercomputer. Additionally, it opens a new path to perform faster research and development.

“You could efficiently use this algorithm to potentially find lighter materials with minimal resources without sacrificing safety or accuracy,” Montes de Oca Zapiain says.

The ML algorithm Material Data Driven Design – MAD3 (mad cubed) – works because metal alloys are made of microscopic, crystallographic grains. Collectively, these grains form a texture that makes the metal stronger in some directions than others, a phenomenon called mechanical anisotropy.

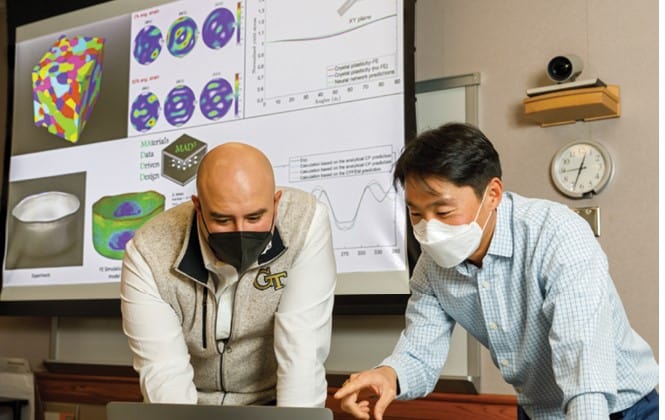

“We’ve trained the model to understand the relationship between crystallographic texture and anisotropic mechanical response,” Montes de Oca Zapiain explains. “You need an electron microscope to get the texture of a metal, but then you can drop that information into the algorithm, and it predicts the data you need for the simulation software without performing any mechanical tests.”

Teaming with The Ohio State University, Sandia trained the algorithm on the results of 54,000 simulated materials tests using a technique called a feed-forward neural network. The Sandia team then presented the algorithm with 20,000 new microstructures to test its accuracy, comparing the algorithm’s calculations with data gathered from experiments and supercomputer-based simulations.

“The developed algorithm is about 1,000x faster than high-fidelity simulations. We’re actively working on improving the model by incorporating advanced features to capture the evolution of the anisotropy since that’s necessary to accurately predict the fracture limits of the material,” says Sandia scientist Hojun Lim, who also contributed to the research.

The National Nuclear Security Administration funded the ML research through the Advanced Simulation and Computing program.

Sandia National Laboratories Advanced Simulation and Computing

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Explore the April 2022 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Ralliant to establish global headquarters in North Carolina

- Philatron MIL-DTL-3432 military cables

- Beyond Aero refines its hydrogen-electric light jet

- Americase's advanced protective solutions

- Social media - what are your thoughts

- GE Aerospace secures Air Force engine contract

- Thomson Industries' online sizing and selection tool

- #53 - Manufacturing Matters - 2024 Leaders in Manufacturing Roundtable