PRAB

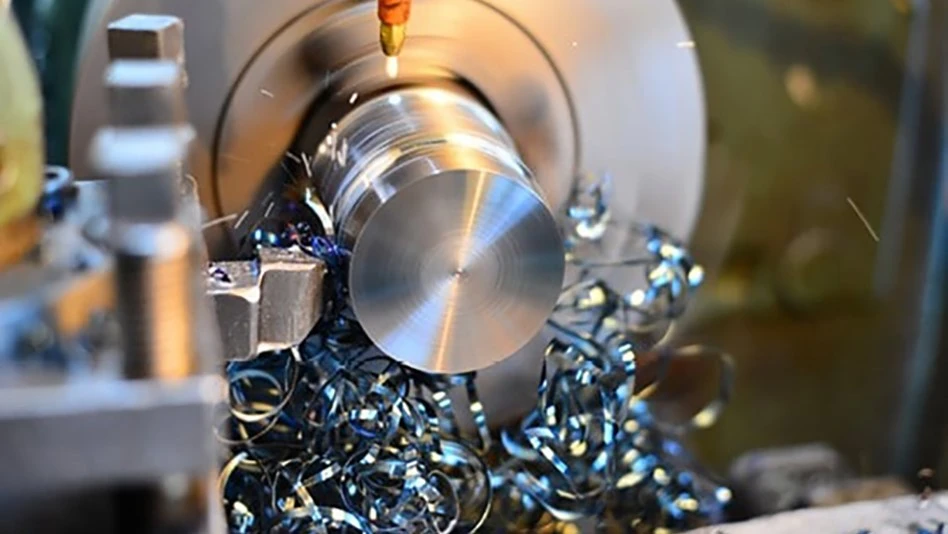

When production is constrained due to circumstances beyond the control of manufacturers, decision-makers look for ways to cut costs to shore up the bottom line. Reviewing the company’s metal scrap processing is a good place to start.

Here are six ways automated metal scrap processing solutions create a pathway for sustainable savings and higher prices from metal scrap recyclers.

1. Lower cutting fluid purchases. Proper cutting fluid’s impact in aerospace manufacturing can’t be underestimated. Using optimal cutting fluid helps fabricators meet tolerances and approval requirements, and it protects tooling and machinery.

When accounting for the costs of cutting fluids for a finished part, estimates swing from 1% to 10%. At $1,500 to $2,300 per drum of cutting fluid, taking measures to maximize fluid utilization is essential.

By removing tramp oils and suspended solids, controlling bacteria, and adjusting fluid concentration, centralized coolant recycling systems enable aerospace manufacturers to recover and reuse valuable cutting fluids. Through filtration and recycling, fluid life is extended 2x to 5x more than typical change-out periods; helping reduce new fluid purchases up to 75%.

2. Extend tool life. Lubricants remove heat from the cutting zone. Maintaining fluid to the manufacturer’s recommended concentration level is essential to providing adequate lubricity for protecting the machine tool. The fabrication process suffers when cutting fluid performance is compromised by off-spec concentration levels, tramp oils, metal fines, and bacteria. Tools begin to weaken, drives are forced to work harder to operate the machine tool, and part quality diminishes.

Tool replacements cost time and money. Perishable tooling is estimated to represent 3% to 6% of total manufacturing costs, while tool replacement contributes to higher cycle times. Using solutions such as centralized fluid recycling, tramp oil separators, or oil recycling systems to remove contaminants extends machine and tool life. Studies show equipment designed to decontaminate cutting fluids extends tool life up to 25%.

3. Higher metal scrap revenue. Metal scrap coated in cutting fluid garners a lower price from scrap dealers than dry metal scrap. By using centrifugal force to remove cutting fluids from chips, wringers reclaim up to 98% of cutting fluids to produce dry chips. Briquetters that compress metal scrap to produce dry, compact pucks can extract up to 95% of fluid for reclamation. Both automated solutions are shown to increase scrap value up to 25%.

4. Lower haul-away/compliance costs. Pass-through costs to meet waste treatment regulation; rising fuel costs; driver shortages; transportation maintenance, equipment, and licensing; and insurance costs all factor into haul-away and disposal costs that erode bottom lines. With costs to transport and treat industrial hazardous waste unlikely to decrease, and environmental compliance requirements likely to increase, metalworking operations can expect these costs to rise in tandem.

Although most logistics variables are outside metalworking shops’ control, there are three areas of metal scrap and fluid waste management that aerospace machining operations can dial in to reduce disposal costs:

High volumes of metal scrap: The bulky shapes and sizes of metal scrap combine to produce a mass of material that is low density and high volume. If it’s coated in cutting fluid, it’ll also be heavy. The more volume there is to haul, the higher the disposal costs. Metal scrap processing systems such as crusher-wringer or shredder-wringer systems can reduce metal scrap volume as much as 90%.

Wasted container space: Left unprocessed, metal scrap is asymmetrical and creates pockets of unused space within bins and containers. Wasted container space yields lower returns and can require additional pick-ups from the hauler. Metal-scrap load-out systems that reach hard-to-fill areas of containers evenly distribute metal scrap so higher volumes of metal scrap can be hauled away per trip.

5. Labor savings. By eliminating manual processes, automated material handling equipment and fluid recycling systems lower labor costs. Conveyors eliminate the need for operators to load and transport metal scrap in bins/containers and support continuous processing. Requiring minimal operator involvement, centralized fluid recycling systems free up personnel previously dedicated to fluid maintenance. Metalworking operations that can use hours previously dedicated to manual processes will better leverage workforce output.

6. Less downtime. Automated solutions eliminating manual processes also decrease downtime, yielding higher productivity and throughput. For example, using application-appropriate conveyors to automate manual material handling processes can raise productivity up to 60%. They also reduce opportunities for human error and decrease floor traffic that creates inefficiencies.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Explore the April 2022 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Beyond Aero refines its hydrogen-electric light jet

- Americase's advanced protective solutions

- Social media - what are your thoughts

- GE Aerospace secures Air Force engine contract

- Thomson Industries' online sizing and selection tool

- #53 - Manufacturing Matters - 2024 Leaders in Manufacturing Roundtable

- Join us for insights on one of the hottest topics in manufacturing!

- You can still register for March’s Manufacturing Lunch + Learn!