GIE Media

1) Sekisui Voltek.

The company is a subsidiary of Sekisui Chemical, a prominent Japanese company with subsidiaries around the world. Located in Coldwater, Michigan, Sekisui Voltek has sales offices in California and Massachusetts. With more than 50 years of experience, Sekisui Voltek has never stopped creating new, innovative products. Sekisui Voltek’s in-house research and development (R&D) team creates foam backed by science. Sekisui Voltek’s four main product lines are:

2) Extremely Lightweight.

Soflton LHR is one of the lightest foams designed to meet aerospace needs. It has an 80% weight savings compared to a solid polymer. Why is this important? Think of all the money you or your customers could save on fuel due to increased fuel efficiency. Also, the lighter the plane is by design, the more weight it can carry as it takes your customers to new destinations.

3) Luxury Aesthetics.

Softlon LHR is designed to have a soft-touch feel without compromising strength. It’s engineered for comfort and can be customized to meet your needs. This foam can be thermoformed into many shapes, including the curvature of the shells, suites, and interior panels. It can be fitted inside them for an added soft touch of luxury. It’s also extremely durable and is non-particulating. It’s designed with consistent cell structures. Softlon LHR is formed in continuous rolls for easy lamination, plus the foam is adhesive friendly. You can upgrade your passengers’ experience, even if they’re already flying first class.

4) Non-Toxic.

Soflton LHR has one of the lowest toxicity rates because it’s made of olefin. Softlon LHR is chemical resistant, making it the safer option for your customers. It has a low volatile organic compound (VOC), which means there’s no distinct plastic scent. This removes the risk of harmful side effects from VOC. Softlon LHR is also formaldehyde-free. Softlon LHR is a closed-cell foam; therefore, it doesn’t allow moisture to be trapped. This makes it naturally resistant to viral and bacterial growth.

5) Safety Regulations.

Softlon LHR meets all current aerospace safety regulations. Softlon LHR meets the Federal Aviation Administration’s (FAA) regulations, including vertical burn rate, heat release, and smoke density. Softlon LHR passes the FAA tests with a margin large enough for other materials to be laminated. Softlon LHR meets original equipment manufacturer (OEM) specifications such as toxicity gas emission for flaming and non-flaming materials.

Learn more about Sekisui Softlon LHR Foam: https://www.sekisuivoltek.com/products/softlon

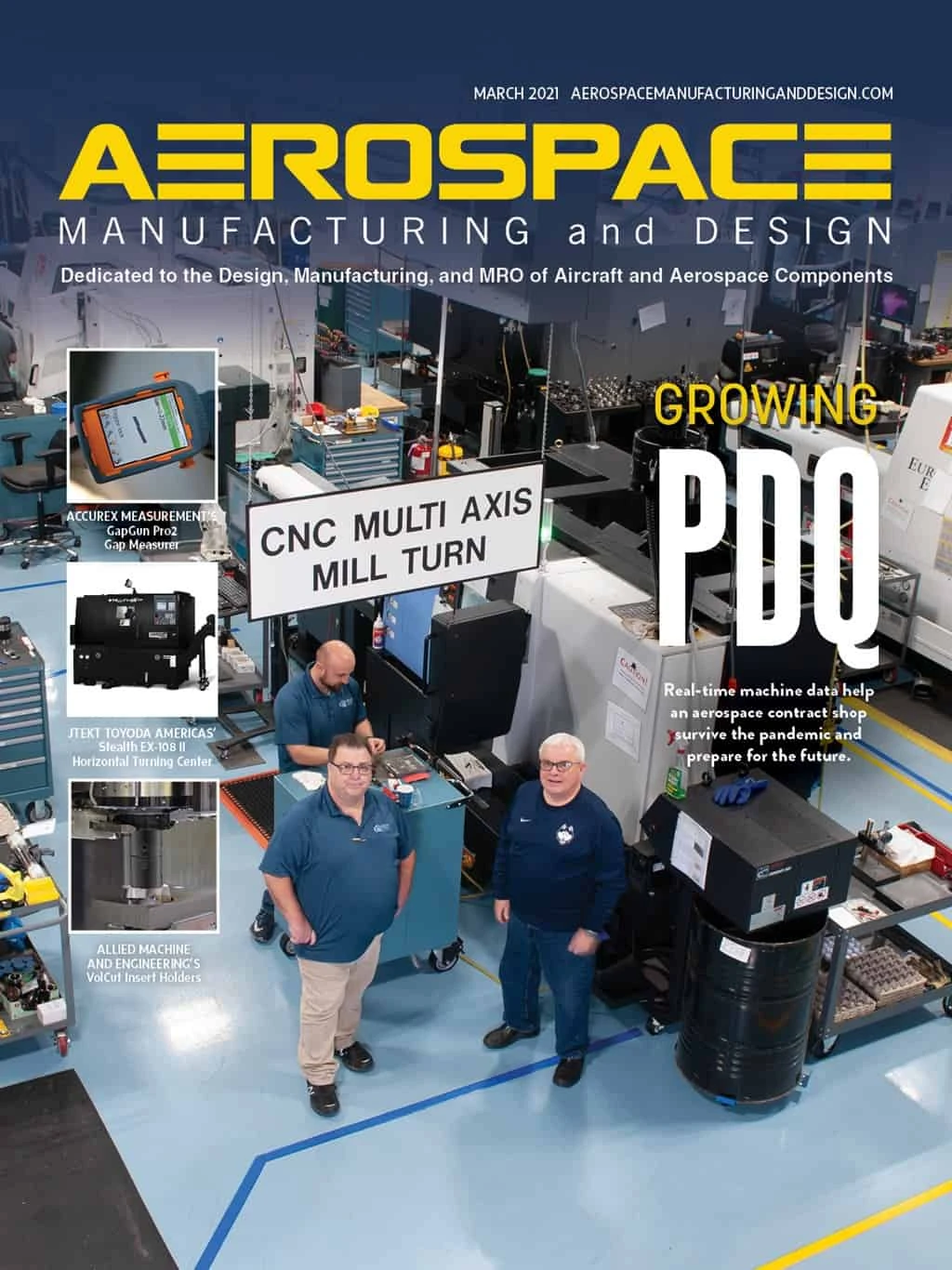

Explore the March 2021 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Talking machine tools with the professionals who build them

- Tools and strategies for improving your machining processes

- America Makes announces QTIME project call

- Innovation meets precision for 40% faster machining

- Upcoming webinar: Pro tips from a supply chain strategist

- Heart Aerospace relocates to Los Angeles

- Fixtureworks introduces Stablelock Clamps

- Piasecki acquires Kaman's KARGO UAV program