GIE Media

1) Technical ceramics

1) Technical ceramics

such as alumina, zirconia, and sapphire can significantly improve the performance of components subjected to extreme conditions, especially in aerospace and defense applications. This becomes extremely valuable when other materials such as steel and glass are susceptible to fatigue/failure and not warranted in complex applications. The advantage to using technical ceramics versus other materials such as steel, glass, and plastics in aerospace/defense applications is most recognizable when high-temperature environments are required. Sapphire can be advantageous for lenses and windows exposed to abrasive, gritty environments as they offer superior scratch resistance. Sapphire also transmits infrared (IR) even at high temperatures.

2) A fabrication specialist,

rather than a raw material producer, is needed for special aerospace/defense applications. A machining specialist that works only on grinding ceramics can be invaluable for achieving precision parts. The specialist can balance sophisticated machine capabilities against tools and fixturing needs and gauge the material response to grinding techniques.

3) Diamond grinding.

While metals are typically machined by single-point cutting, this technology doesn’t work on fired ceramics because they are generally harder than the cutter itself. Machining using grinding wheels with diamond grit embedded in metals or composites removes the material by impact. This process allows for remarkably tight tolerances and fine features that will remain stable far longer than other materials.

4) Accuracy and tolerances.

With the philosophy “if you can’t measure it, you can’t make it,” Insaco has evolved an elaborate quality control (QC) program with best-in-class contact and non-contact instruments. This allows us to measure and document processes and assure parts are made to print or they don’t ship.

5) Technical aerospace, defense, and semiconductor applications.

For 75 years, Insaco’s management has committed to continuous capital upgrades to facilities, cutting edge equipment, and the expertise to work with this equipment. Our upgrades enhance dependability, add form capabilities, consistently achieve tighter tolerances, and increase capacity for our customers’ needs. Insaco is free to procure materials without bias from the most appropriate resource. This can involve size, availability, delivery times, grain size, purity, and of course cost. The emphasis on hiring top-level machinists is to ensure we are capable of delivering what we promise. Insaco engineers are available to talk through a designer’s requirements to help specify the best ceramic material and to analyze drawings from a fabrication perspective to highlight cost driving details before a design is finalized.

Insaco Inc.

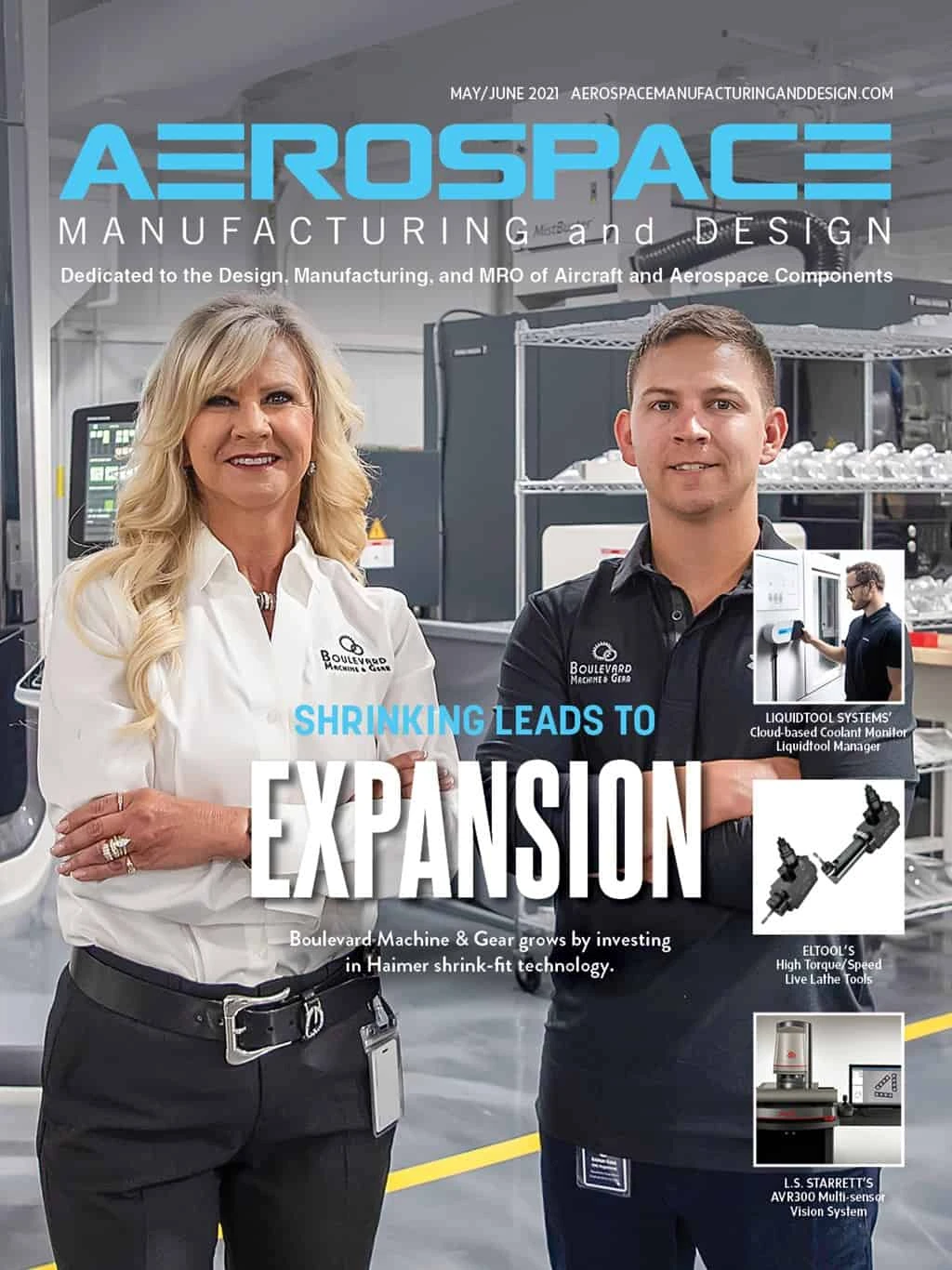

Explore the May June 2021 Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Reamer re-tipping extends life of legacy tooling

- Revitalizing the Defense Maritime Industrial Base with Blue Forge Alliance

- Safran Defense & Space opens US defense HQ

- Two miniature absolute encoders join US Digital’s lineup

- Lockheed Martin completes Orion for Artemis II

- Cylinder CMMs for complex symmetrical workpieces

- University of Oklahoma research fuels UAS development

- Motorized vision measuring system