1. How do metrology solutions add dimensional control when machining precision parts?

All machining operations have inherent variation caused by machine positioning errors, material variances, fixturing, tooling load, and thermal changes. Many companies employ metrology at the end of machining to ensure that good parts go out the door, but it does little to improve manufacturing efficiency.

As a high-precision manufacturer, Renishaw has learned that applying metrology before and during machining processes keeps operations in tight control, significantly improving process yield and final part quality at a much lower cost of production. This is especially important as companies move to automated manufacturing where process control is imperative to prevent producing scrap at unprecedented rates. Renishaw views our customers as partners, openly sharing our expertise to help them make the best decisions when implementing process control and final part validation.

2. What types of solutions can be applied?

Renishaw applies solutions using our Productive Process Pyramid which provides a systematic approach to deploying effective process control. The process has 4 steps:

Process Foundation – Machine calibration tools determine a machine’s capability and compensate to improve a machine’s accuracy. Our QC20W Ballbar, XL80 Laser, XM60 Volumetric Laser, and XR20W Rotary Calibrator can calibrate virtually any metal cutting machine. Most major machine tool builders use these devices to ensure accuracy during build and installation, but they are more frequently used directly by companies that want to maintain machines with the highest level of capability. These products provide direct traceability to national and international standards such as ANSI B5 and ISO 230.

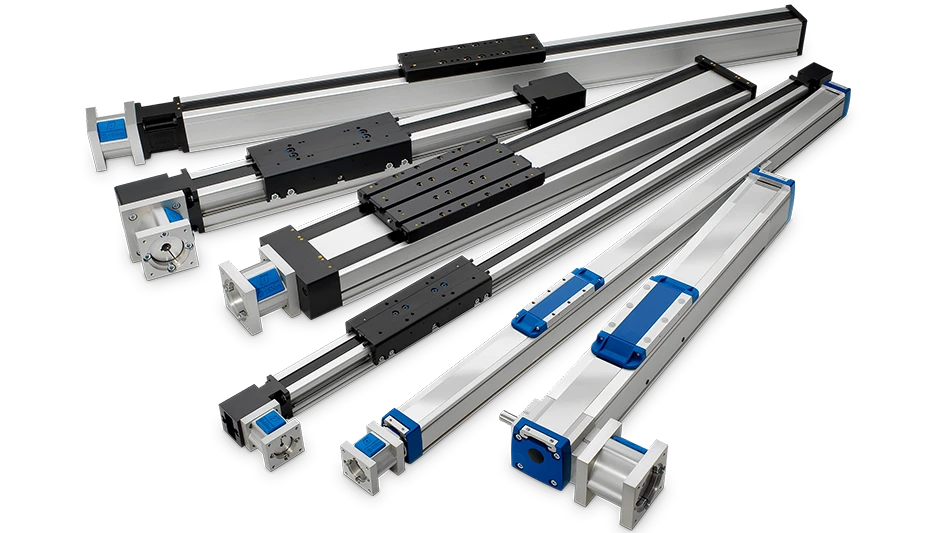

Process Setting – Establish the location of fixturing, workpiece, and tooling within machine travels, just prior to cutting. Renishaw makes an assortment of probing systems and software that are available, factory installed, on most major brands of metal cutting machines and can also be retrofit to existing machines at our customer’s factories. Dual probing packages such as the OMP/OTS or RMP/RTS systems provide wireless operation of both part and tool setting probes from a single interface. These systems support fully automatic operation that greatly reduces setup time while increasing overall precision.

In-Process Control – Use metrology to make automated adjustments while the machine is in cycle to control variation that is inherent in all processes. For low-volume/high-value operations a cut-measure-cut strategy – where a cut is made then the result is measured and an offset is applied to a final cut – brings the feature directly into nominal dimension, all automatically. Using our new Supatouch or Supascan packages and accompanying probing systems enables companies to employ this type of in-process measurement at speeds previously unobtainable. For higher volume/short cycle time operations, our Equator Gaging System can measure select features and provide direct work and tool offsetting using our Integrated Process Control (IPC) software.

Post Process Monitoring – Final part inspection provides full understanding of process results. The goal here is to measure all critical features with high accuracy, as quickly as possible, with minimal floor space and operator interaction. To achieve this, Renishaw has developed our Revo 5-Axis Multi-sensor system for Coordinate Measuring Machines (CMMs). The Revo system can measure complicated parts at speeds up to 20x faster than those currently employed by most companies. It employs an infinitely positioning head that has 0.08arc/second resolution encoders and an integral laser positioning system that supports surface scanning speeds up to 500mm/sec. The Revo system is the heart of a growing family of complementary sensors to measure surface finish, vision, and ultrasonic thickness. The combination of 5-axis positioning and automatic sensor changing allows companies to significantly reduce the floor space and manpower required for inspection.

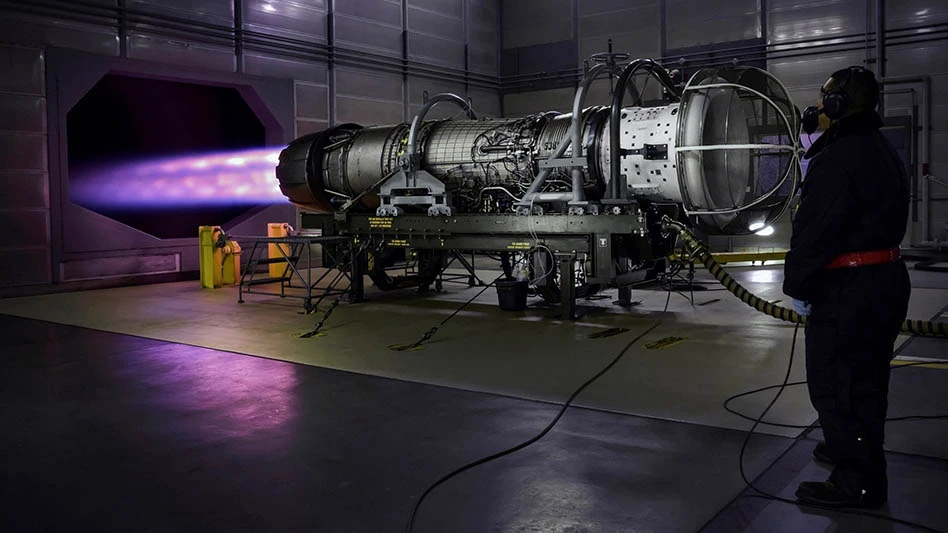

3. How can aerospace manufacturers use metrology systems and data to increase production and reduce the industry’s backlog of unbuilt planes?

The aerospace industry has an enviable problem – more orders than capacity to produce products.

To increase production and reduce backlog, aerospace manufacturers should focus first on reducing or eliminating non-conformance during operations by ensuring process control using the Productive Process Pyramid as a guide. Dimensional problems that are caught after machining are very costly in scrap, rework, and delayed shipments. By ensuring a stable process, scrap and rework can be significantly reduced or eliminated. Then, work on increasing throughput on final certification. Inspection time of critical components can be more than the actual machining time. Renishaw Revo 5-Axis CMM systems have effectively reduced inspection time by up to 90% in aero engine components, significantly reducing backlog.

4. In the medical field, what advances in metrology systems support the smaller, more intricate workpieces needed for modern surgical procedures and implants?

Because each device is implanted in a human, quality is the highest concern for medical manufacturers. Advances in machine tool calibration, such as our XM60 laser that can measure all 6 degrees of freedom (6DOF) in each axis, can provide a comprehensive picture of machine capability – before any machining begins.

Many of the smaller implantable devices are made on Swiss-type turning machines which benefit from our Equator gaging system. The Equator gage can quickly scan components for dimensional accuracy and provide feedback to the process to ensure effective process control. Styli can be fit down to 0.3mm (0.012") to provide access to small intricate features. Advances in non-contact sensors such as our RVP vision sensor on our Revo system can perform final inspection without touching the part.

5. In the motor vehicle space, what systems can manufacturers use to support higher-strength materials needed to support high-torque motors in electric-drive systems?

The automotive industry is going through a rapid change from internal combustion engines to hybrid and full electric powertrains. To remain competitive, automotive machining lines must be flexible to support a shifting product mix. Moves toward programmable Equator gaging are allowing manufacturers to quickly adapt production to new products.

For high-torque drives to be efficient, the dimensional tolerances of fixed and rotating elements must be held very tightly. Form and surface finish of features are also more critical as the mating tolerances are reduced. Renishaw’s Sprint high-speed scanning probe can be employed directly on cutting machines to measure form of features before and during production. Revo high-speed scanning can be used after machining for final validation of size, location, form, and surface finish.

For more information:

https://www.renishaw.com

Explore the Inspection Target Guide Issue

Check out more from this issue and find your next story to read.

Latest from Aerospace Manufacturing and Design

- Drop in for an interactive webinar on automation in manufacturing

- SW’s wing rib technology for the aerospace industry

- Mach Industries launches Mach Propulsion

- Murata Machinery USA's MT1065EX twin-spindle CNC turning center

- Electra reaches 2,200 pre-orders for its Ultra Short aircraft

- Heule's DL2 tooling for deburring of small bores

- Ralliant to establish global headquarters in North Carolina

- Philatron MIL-DTL-3432 military cables